Used NAPSON RG-15D #9240737 for sale

URL successfully copied!

Tap to zoom

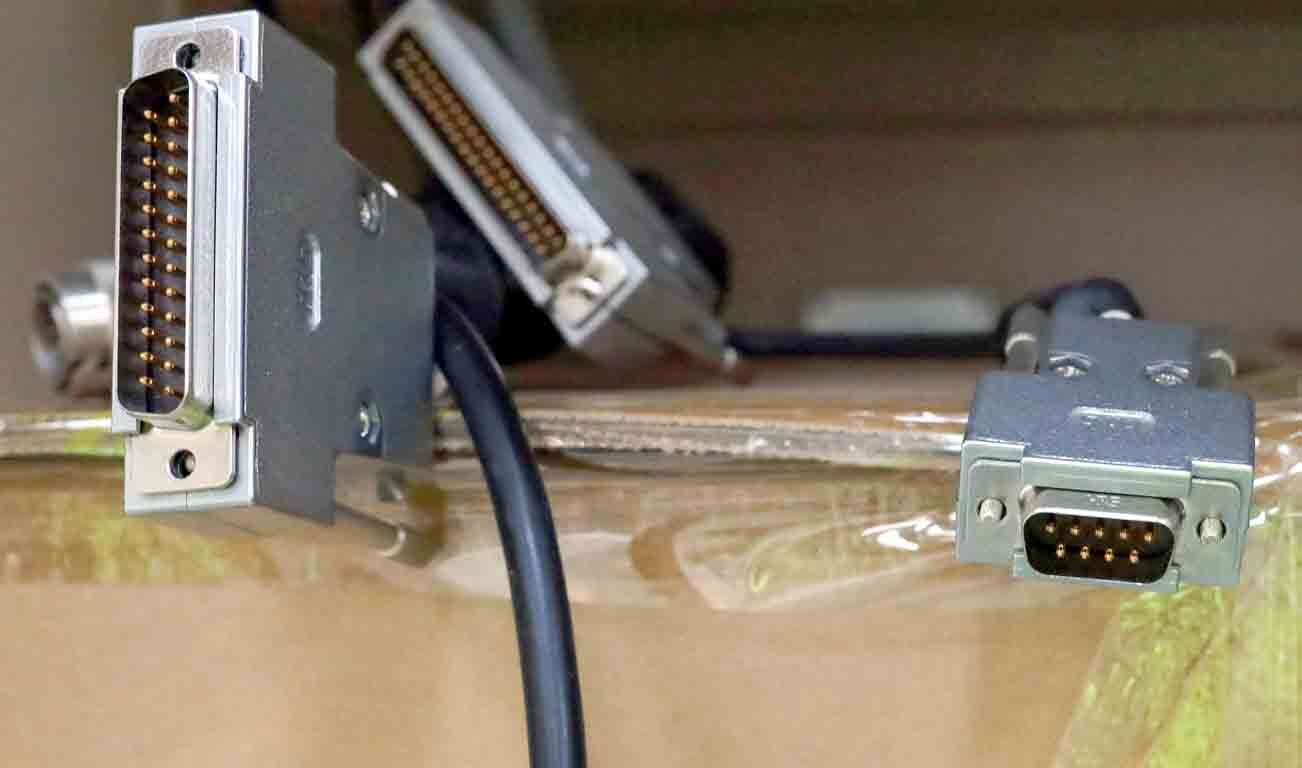

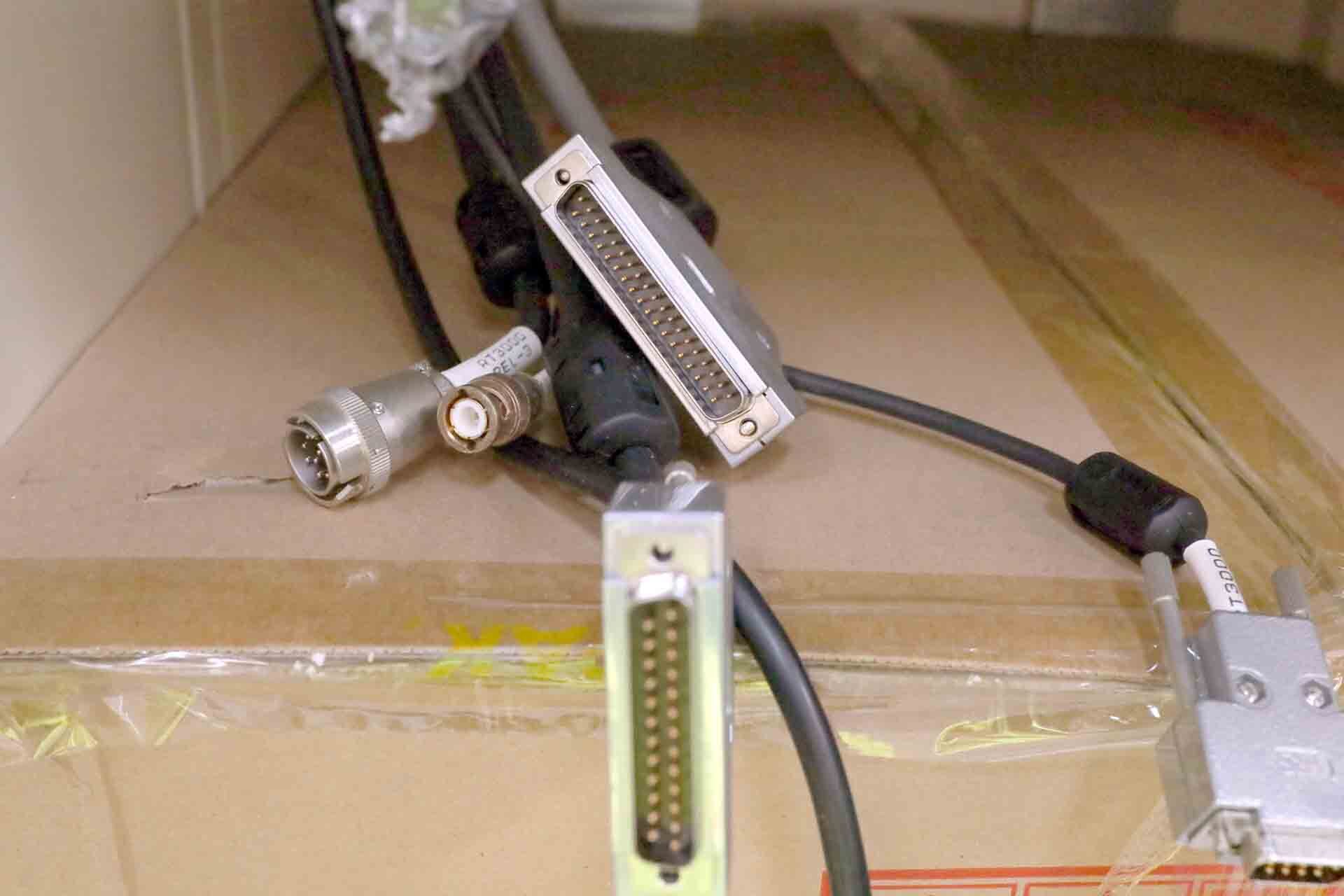

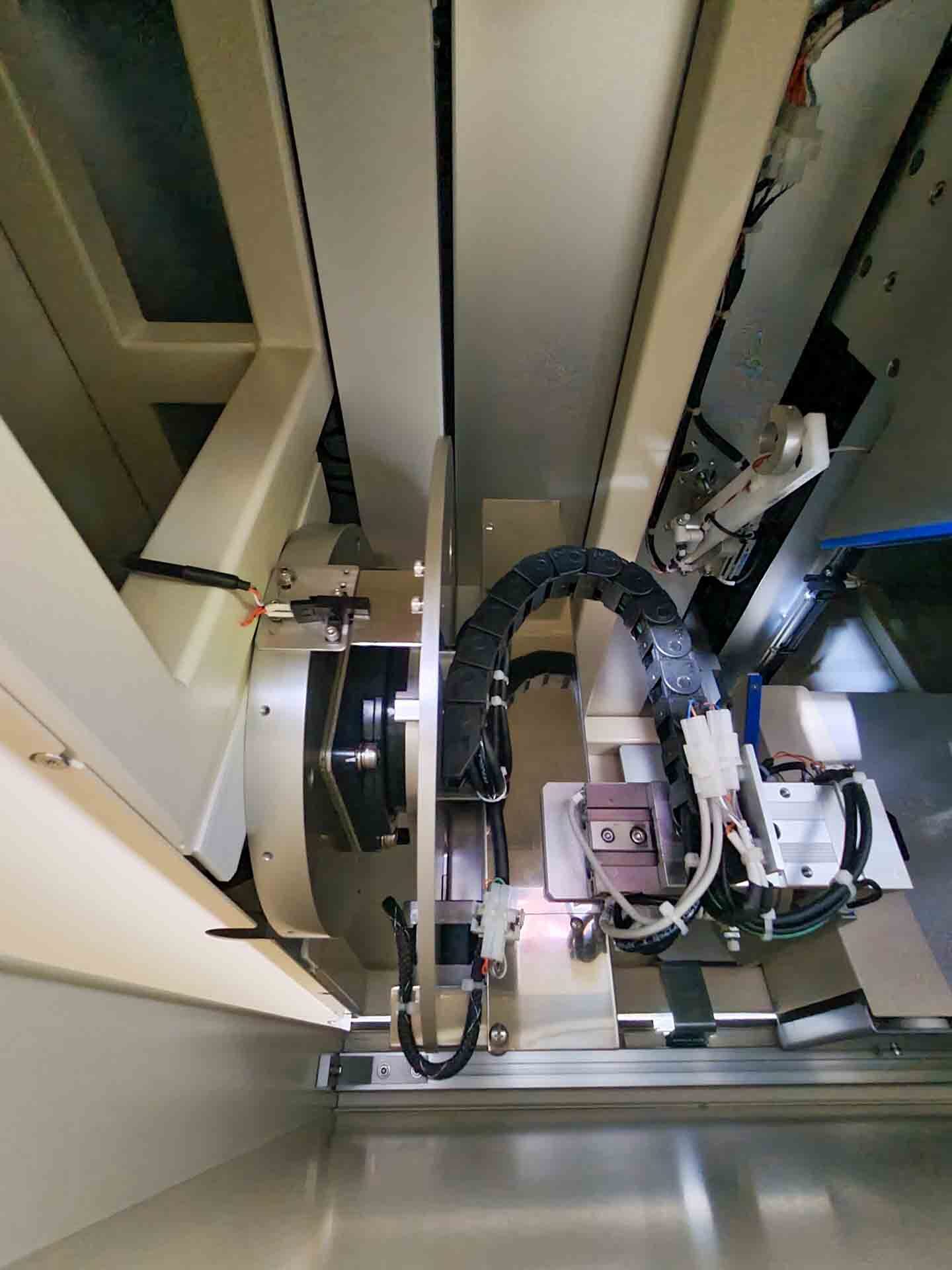

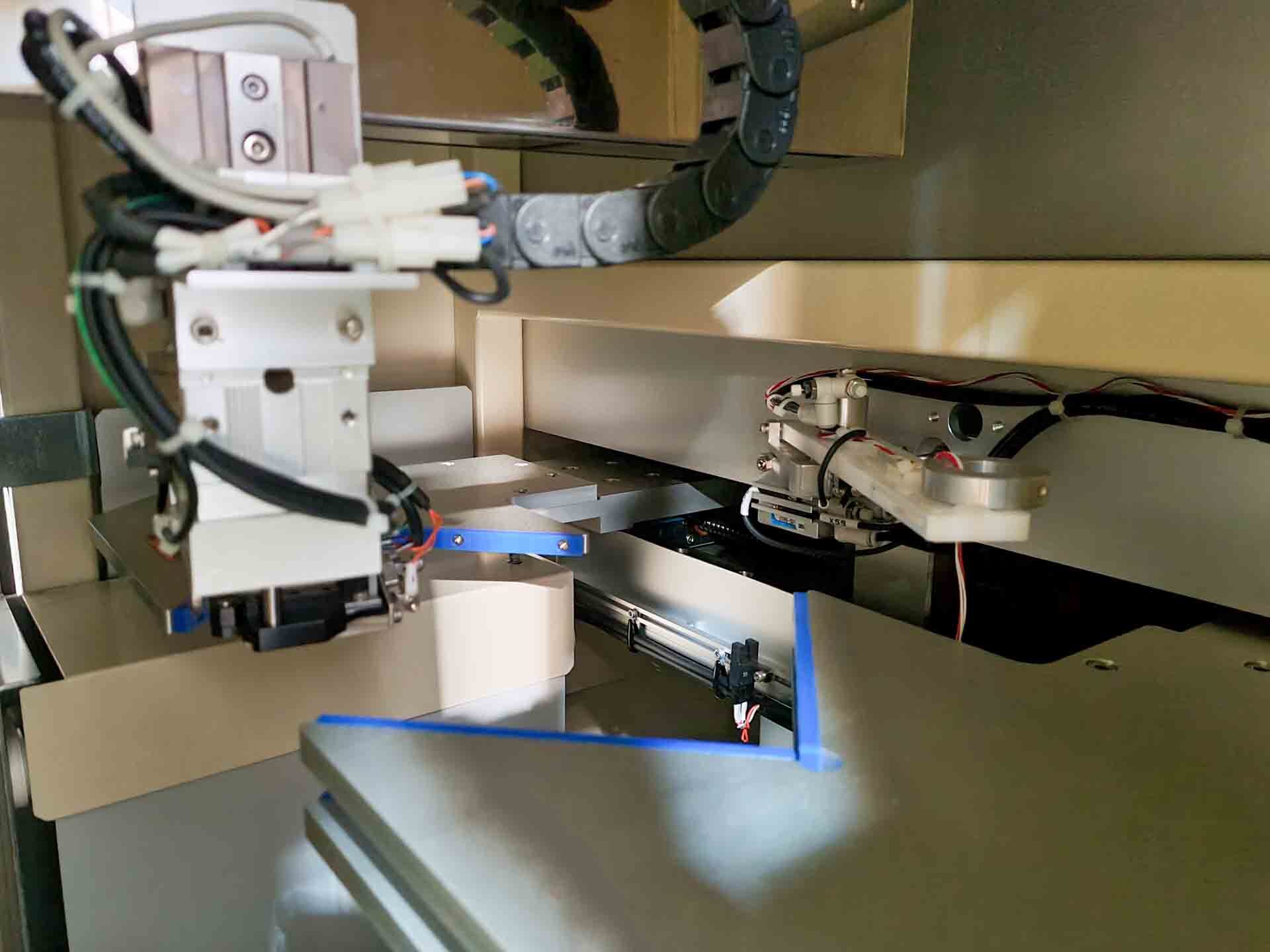

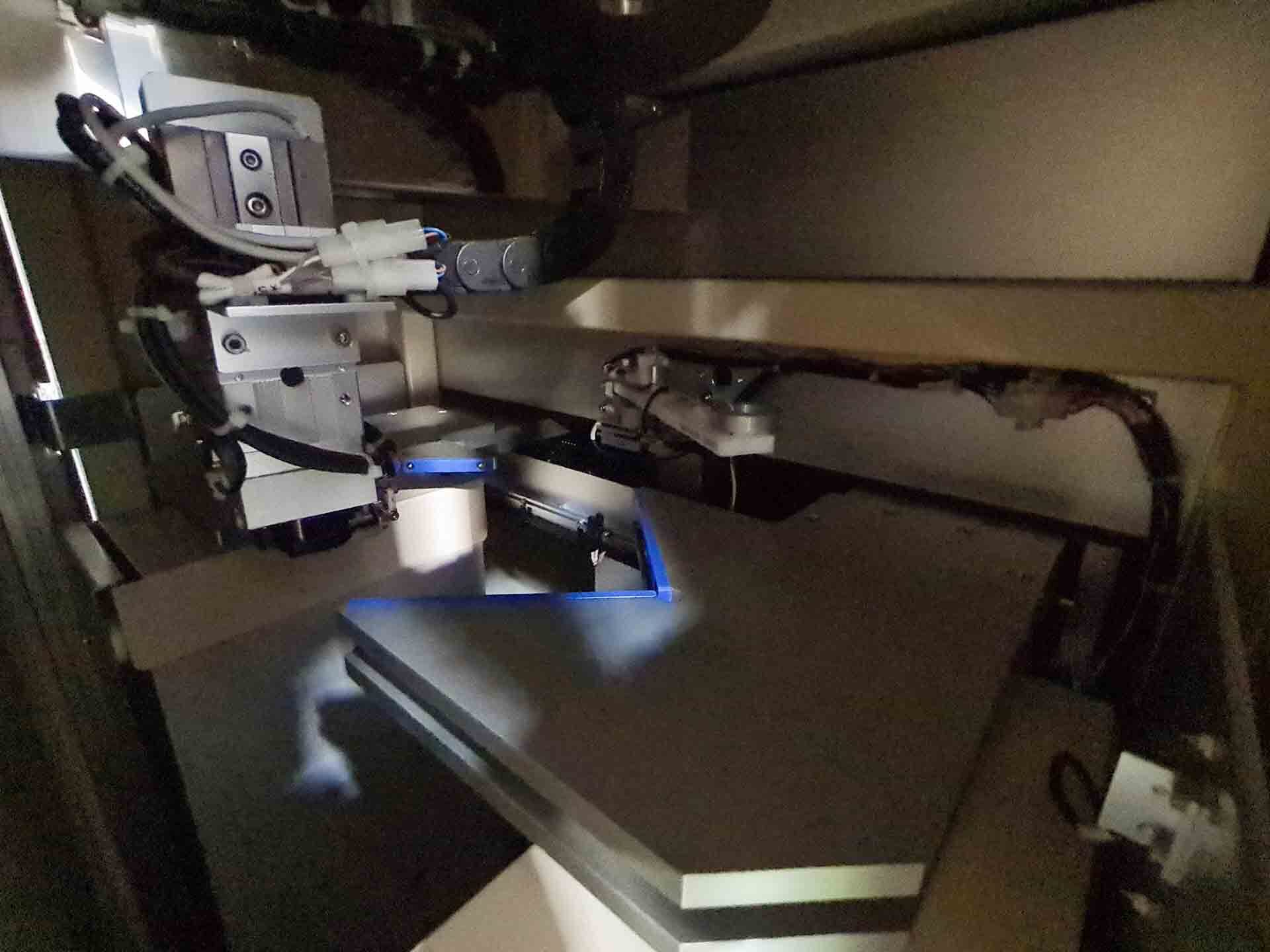

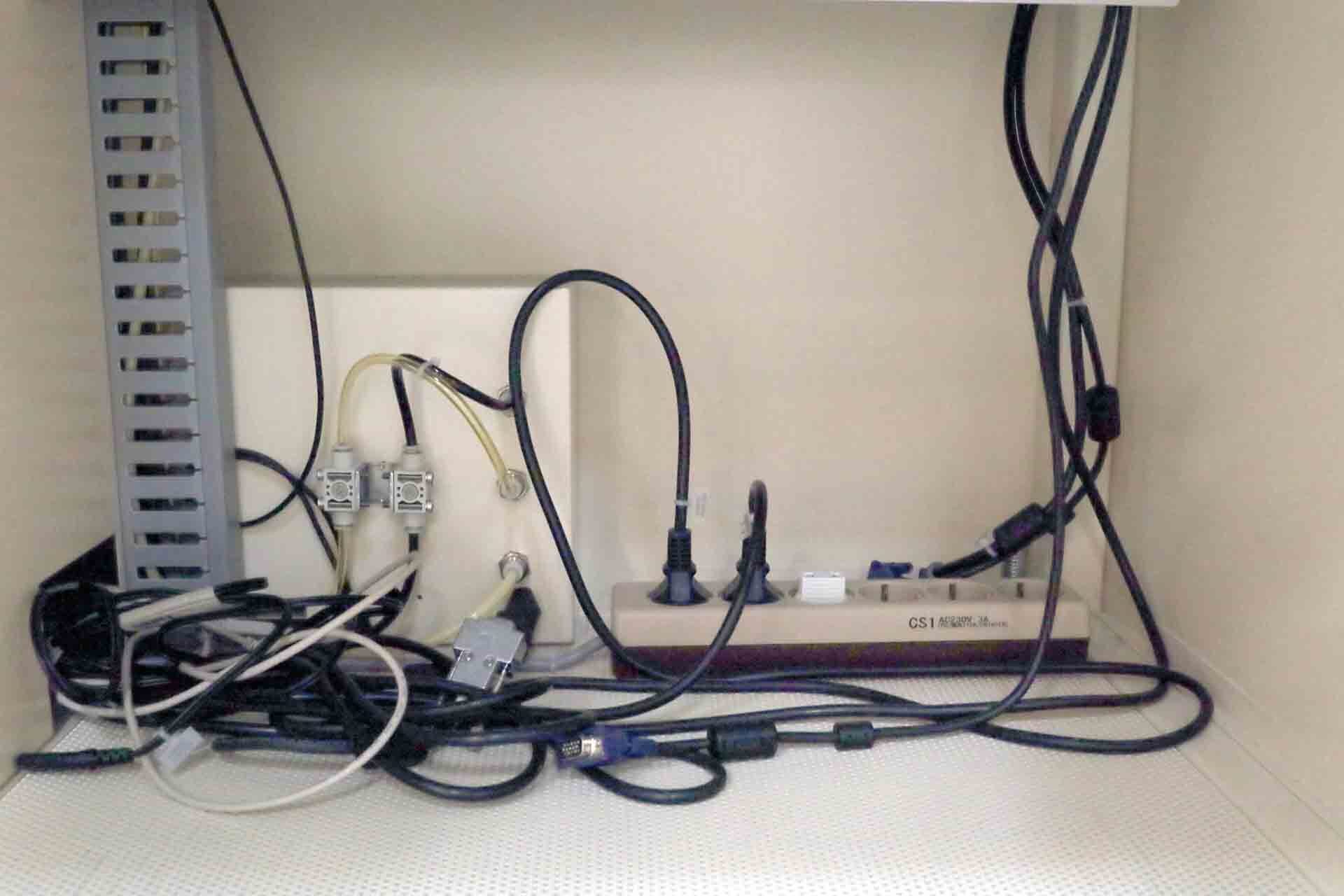

NAPSON RG-15D Mask & Wafer Inspection equipment is a fully automated, high speed, non-contact optical inspection system for the evaluation and inspection of microelectronic masks, LCD panel masks, and wafers. RG-15D combines high magnification, high resolution imaging with a sophisticated optical filtering unit to detect tiny defects and variances in the device under inspection. The machine is capable of imaging without contact up to 45x magnifications and is equipped with two 16 megapixel cameras for capturing high magnification images. NAPSON RG-15D is designed to increase productivity and quality control while reducing inspection time. The tool uses a double central imaging asset, an optical filtering model, and a double-stroke mirror technique to capture the high resolution images. The equipment features a wide field of view and high contrast imaging which makes it able to detect extremely small defects with a minimum of false positives. It captures high resolution images quickly, allowing for inspections to be performed in a matter of seconds. The imaging system is equipped with variable illumination levels and a wide range of adjustable parameters which make it suitable for a wide range of applications. RG-15D Mask & Wafer Inspection unit also features advanced defect detection software. The software is designed to identify defects quickly and accurately and is capable of processing multiple images simultaneously. The software is also able to recognize patterns and apply various analytics such as size, shape, orientation, and other criteria to identify potential defects. The software is also able to evaluate the quality of the product under inspection by matching it to predetermined criteria. The machine also includes a number of industry standard interfaces for integration with other inspection systems and data management systems. NAPSON RG-15D is also equipped with a dry process chamber which is a hermetically sealed, vacuum isolation chamber. This allows for efficient operation in any environment and ensures that all imaging parameters, including background noise, temperature, and humidity, are accurately and consistently maintained. Overall, RG-15D Mask & Wafer Inspection tool is a highly advanced and efficient inspection asset designed to improve productivity and accuracy in the microelectronics manufacturing industry. The model tackles the challenge of inspecting all types of masks and wafers quickly and accurately with an advanced combination of imaging and software technology. The equipment is ideal for a variety of inspection tasks and is capable of producing excellent results in the most demanding of conditions.

There are no reviews yet