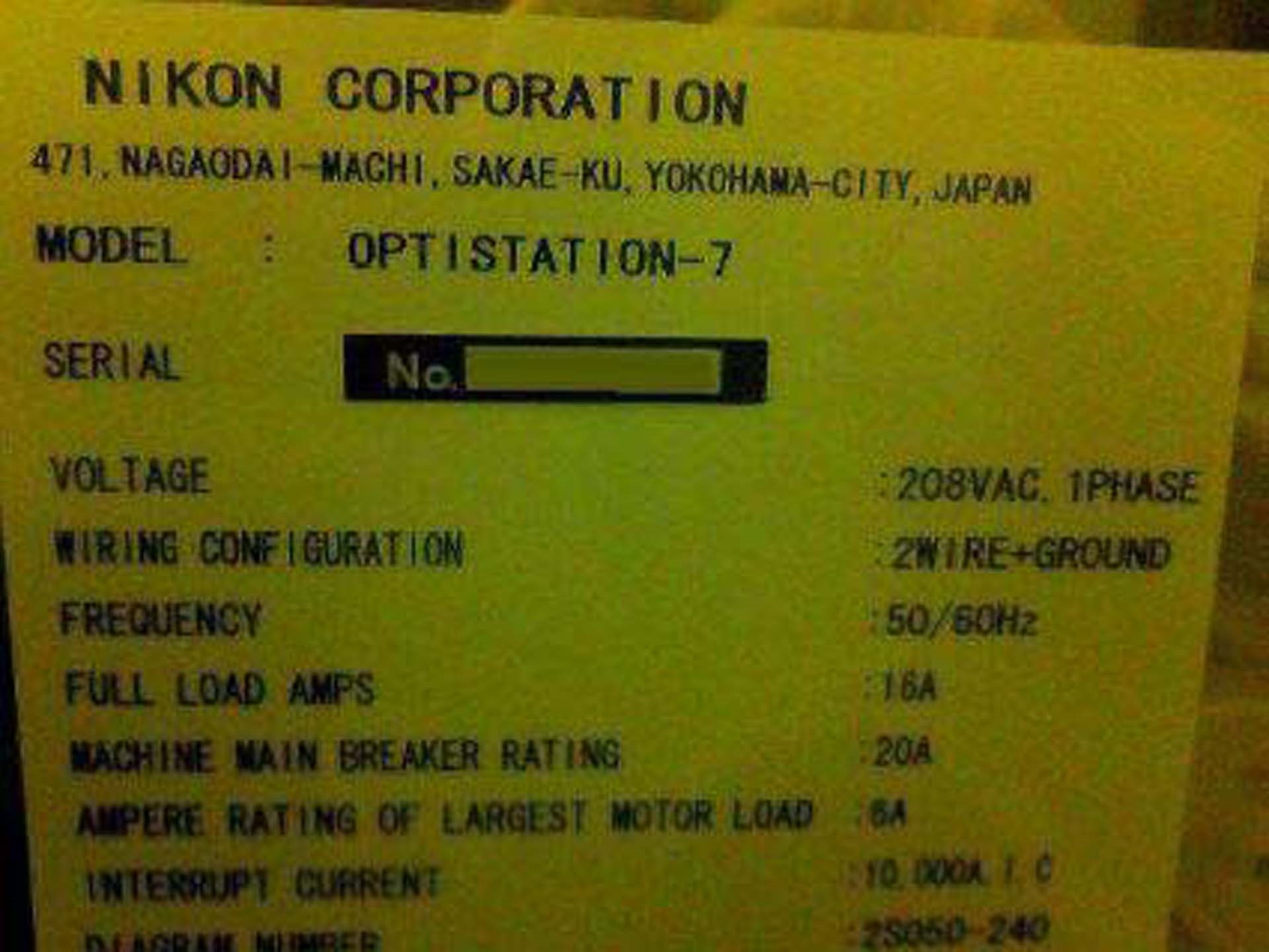

Used NIKON OPTISTATION 7 #9234683 for sale

URL successfully copied!

Tap to zoom

ID: 9234683

Wafer Size: 12"

Vintage: 2007

Wafer inspection system, 12"

Cassette type: FOUP 25 Wafer

Chuck materials: PEEK

Transfer robot

Optical system: BF/DF

Auto forces function

Remote operation: Magnification changer, BF/DF changer, AS, FS

Microscope stage pre-alignment accuracy:

Eccentricity: 3σ ≤ 35µm

Attitude angle: 3σ ≤ 2°

Optical system: Infinity optical

Objective lens: BF/DF Observed BD-PLM 5x, 10x, 20x, 50x, 100x

Eyepiece lens: CFUWN 10x (F.N.25)

Observation tube: Super wide field trinocular tilt observation tube UWTT

Eyepiece angle: 10° to 30°

Motorized revolving nosepiece: Quintuple for BF/DF

Microscope illumination: 12 V, 100 W Halogen lamp

Throughput:

Macro-inspection (2 Sec)

Cassette all point ≤ 6 min 30 sec

Micro-inspection (5-Points, per 1 sec) ≤ 10 min

Auto-focus:

Detective method: LED Illumination slit projection AF

Illumination source LED: Wavelength 770 nm

Observed method: BF/DF

Eyepiece lens: 10x-150x

Stage:

X-Y Stage:

Observed area, 12"

θ Rotation: Rotating angle: 3.5°

Pre-alignment type: Non-contact pre-alignment

Eccentricity: 3σ ≤ 35µm (X,Y)

Attitude angle: 3σ ≤ 2°

Arm type: Belt drive

FOUP (Load port):

ASYST FL300S3 Side loading type port

SEMI (E-15-1) Standard

Alignment load wafer

Illumination source: LED 910 nm

Detector: Photo-transistor (PT)

Eccentricity: Macro-stage ≤ ± 1.5 mm

Macro stage

Surface macro

Auto drive

Tilt angle: Infinity

Speed: ≤ 15 RPM

Angle: -90° to -120°

Special halogen lamp L1L-100

Backside macro: 15 V, 100 W Halogen lamp (Fiber illumination type)

2007 vintage.

NIKON OPTISTATION 7 is a high-end, automated mask and wafer inspection equipment designed for manufacturers who require high-precision optical instruments and advanced automation capabilities. The system provides high-resolution imaging and precise measurement capabilities with a major focus on defect inspection, process evaluation, and yield prediction. The unit features an advanced automated stage for easy loading and unloading of samples. It offers a quad-detector configuration—Fourier, Edge, Broadband Contour, and Shading Inspection—to ensure the highest degree of accuracy and efficiency in the examination process. It also has an enhanced software for efficient image processing and high performance analysis. NIKON OPTISTATION-7 features a high optical resolution of up to 16 megapixel cameras and an image resolution up to 5133 dpi, allowing for highly accurate and precise measurements. The machine also has an adjustable LED illumination tool, enabling it to inspect transparent, diffraction, and diffuser wafer samples. OPTISTATION 7 employs a set of user-friendly, intuitive tools that streamline the inspection process. It allows users to customize parameters such as exposure time, light intensity, focus, and more, to ensure that each sample meets specified criteria. OPTISTATION-7 also maintains minimal downtime with advanced maintenance options and universal programming API. The asset is capable of running automated scripts to inspect up to 4 parts simultaneously, and it can be integrated with inspection systems from other manufacturers via a networkable interface. NIKON OPTISTATION 7 is a reliable instrument for both lithographic and process-driven defects that allows manufacturers to confidently inspect high-end products for reliable performance. With its user-friendly interface, advanced automation capabilities, and high-resolution imaging techniques, the model is sure to deliver reliable, consistent results.

There are no reviews yet