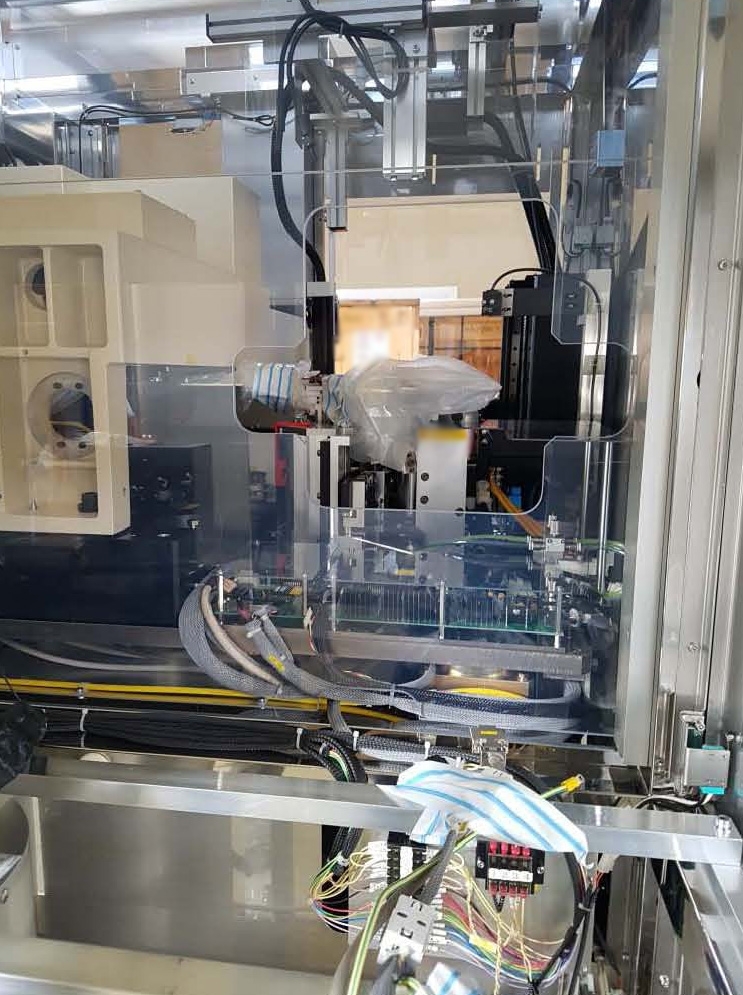

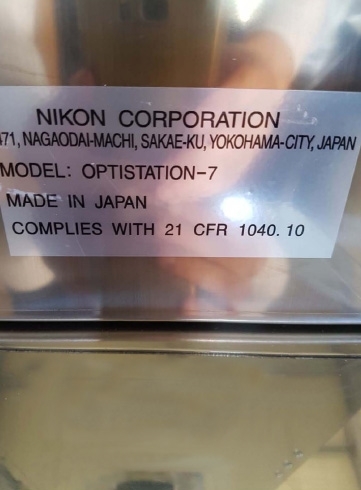

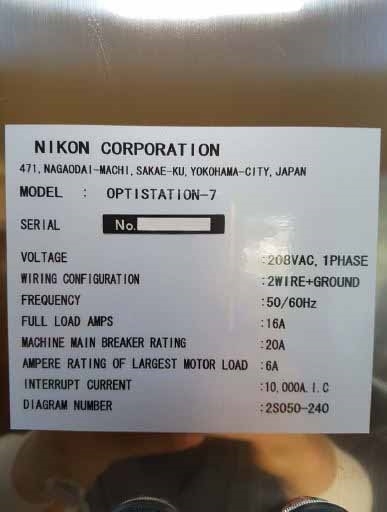

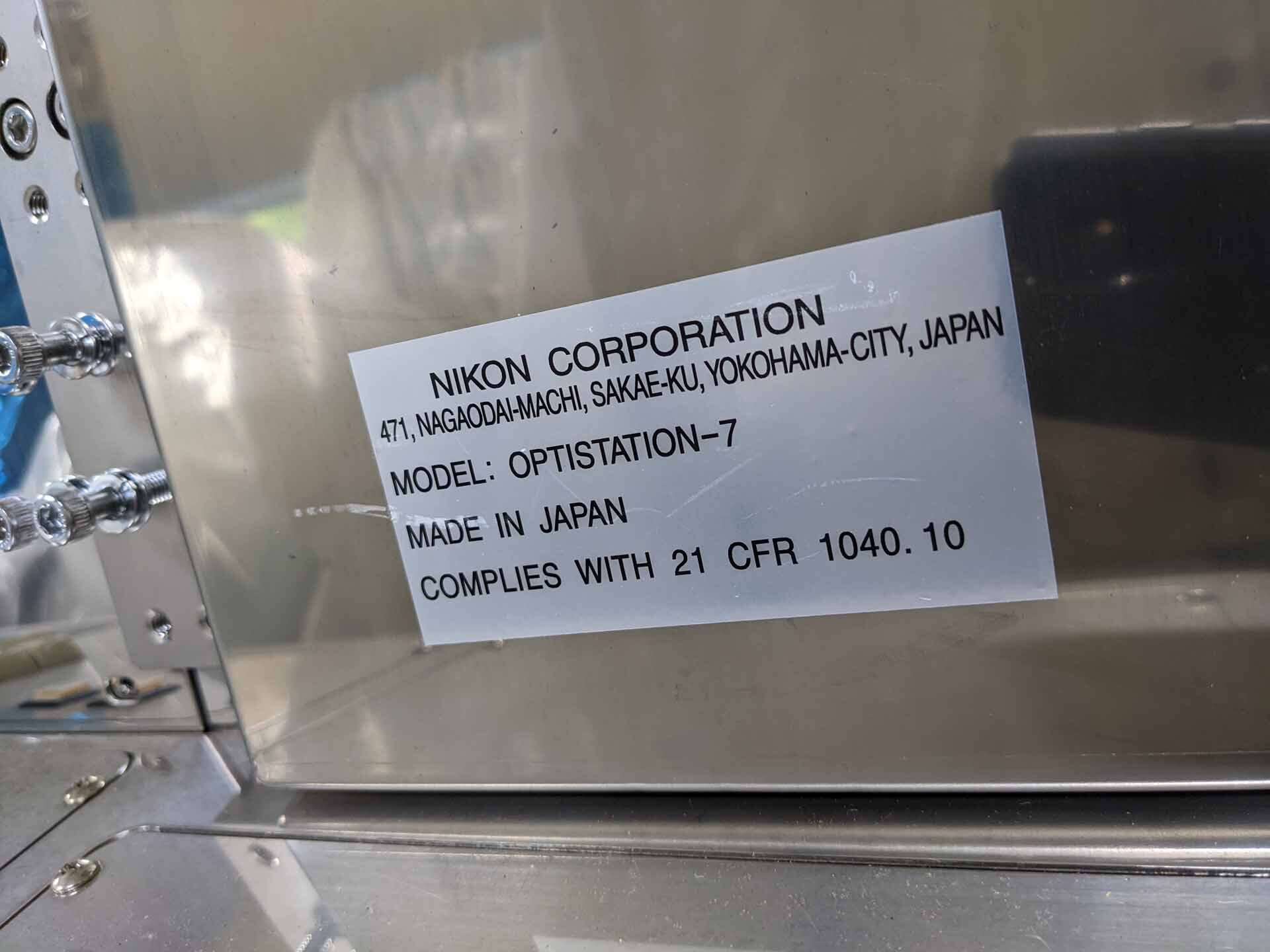

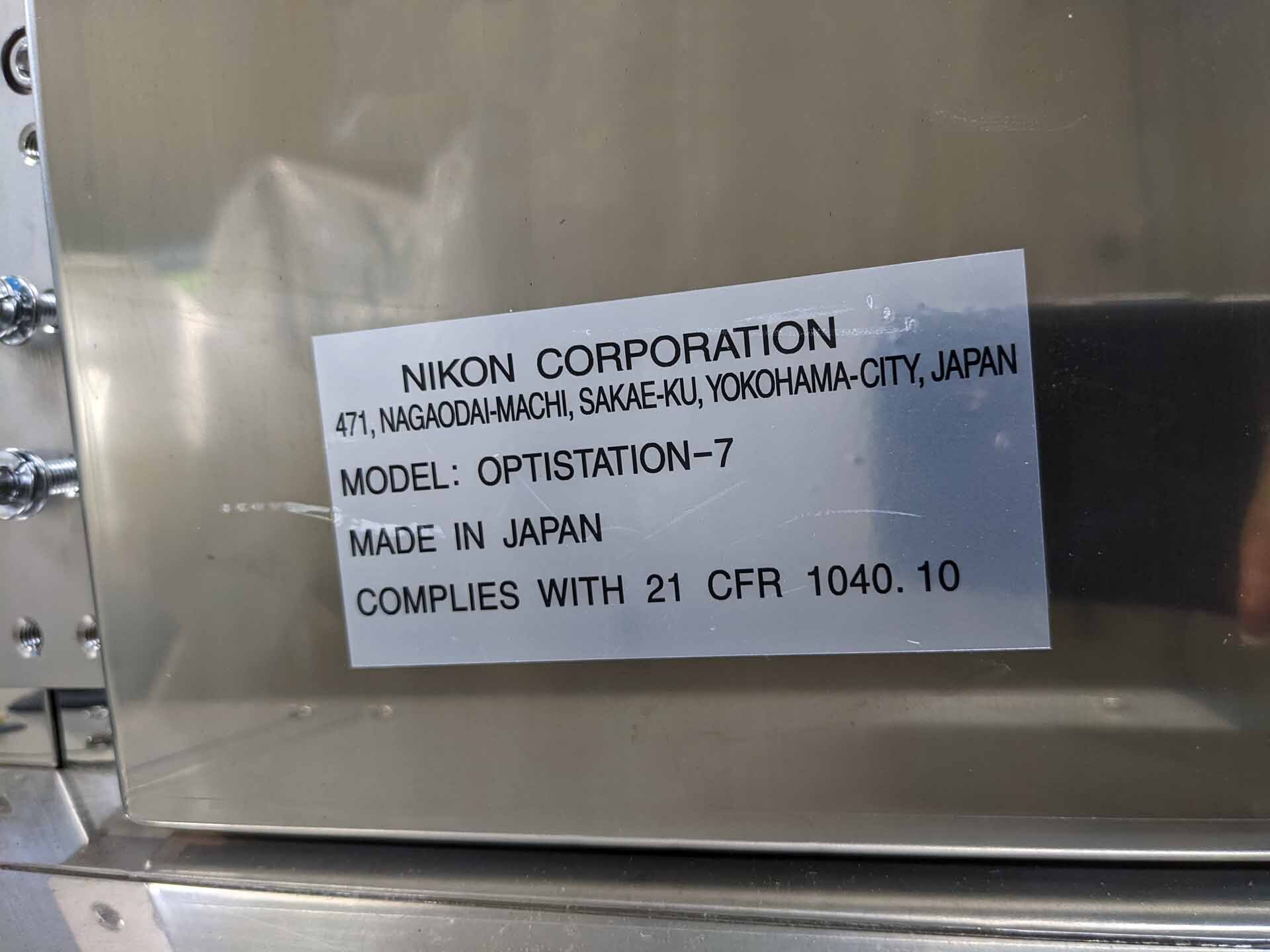

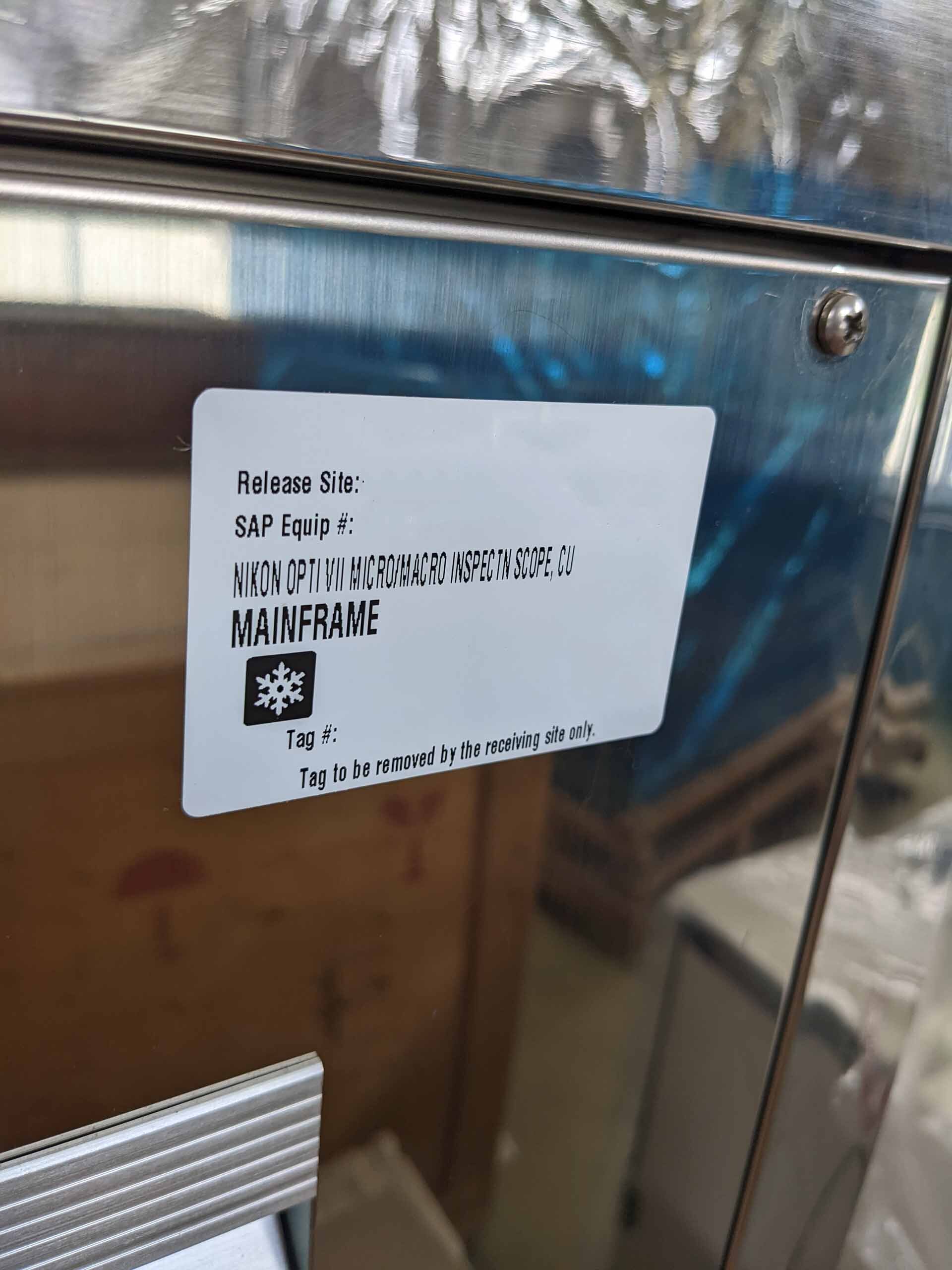

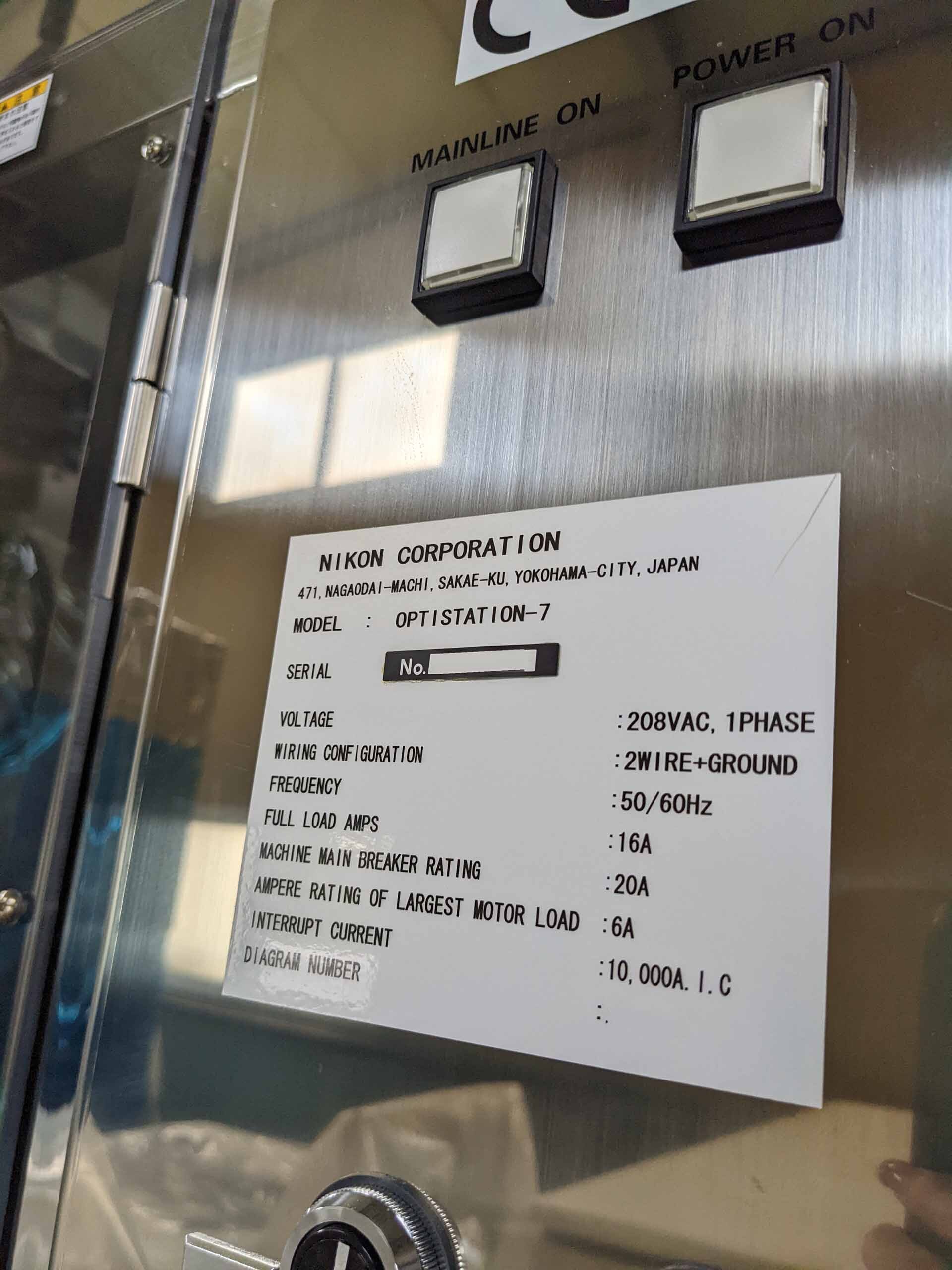

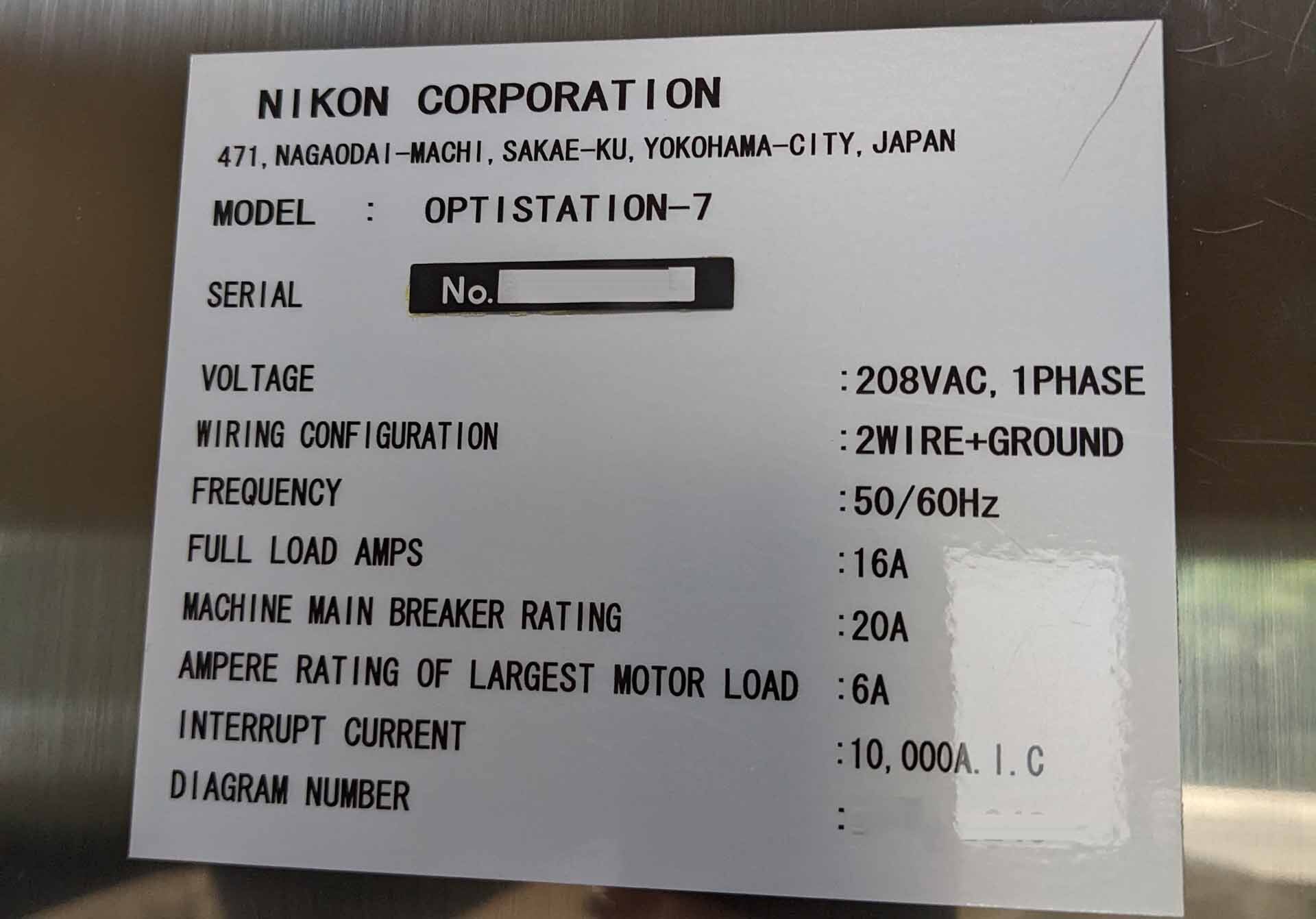

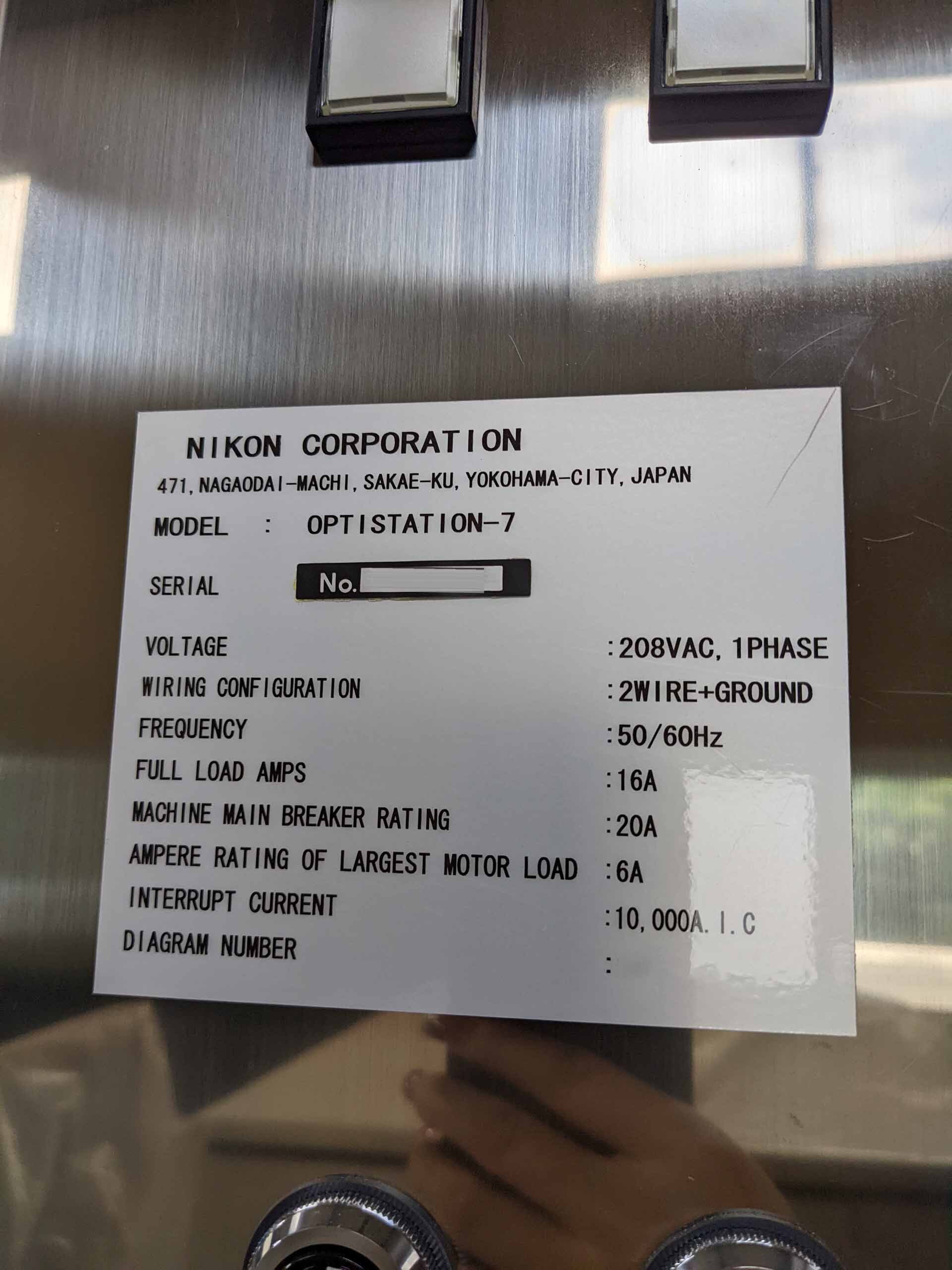

Used NIKON Optistation VII #293592368 for sale

URL successfully copied!

Tap to zoom

ID: 293592368

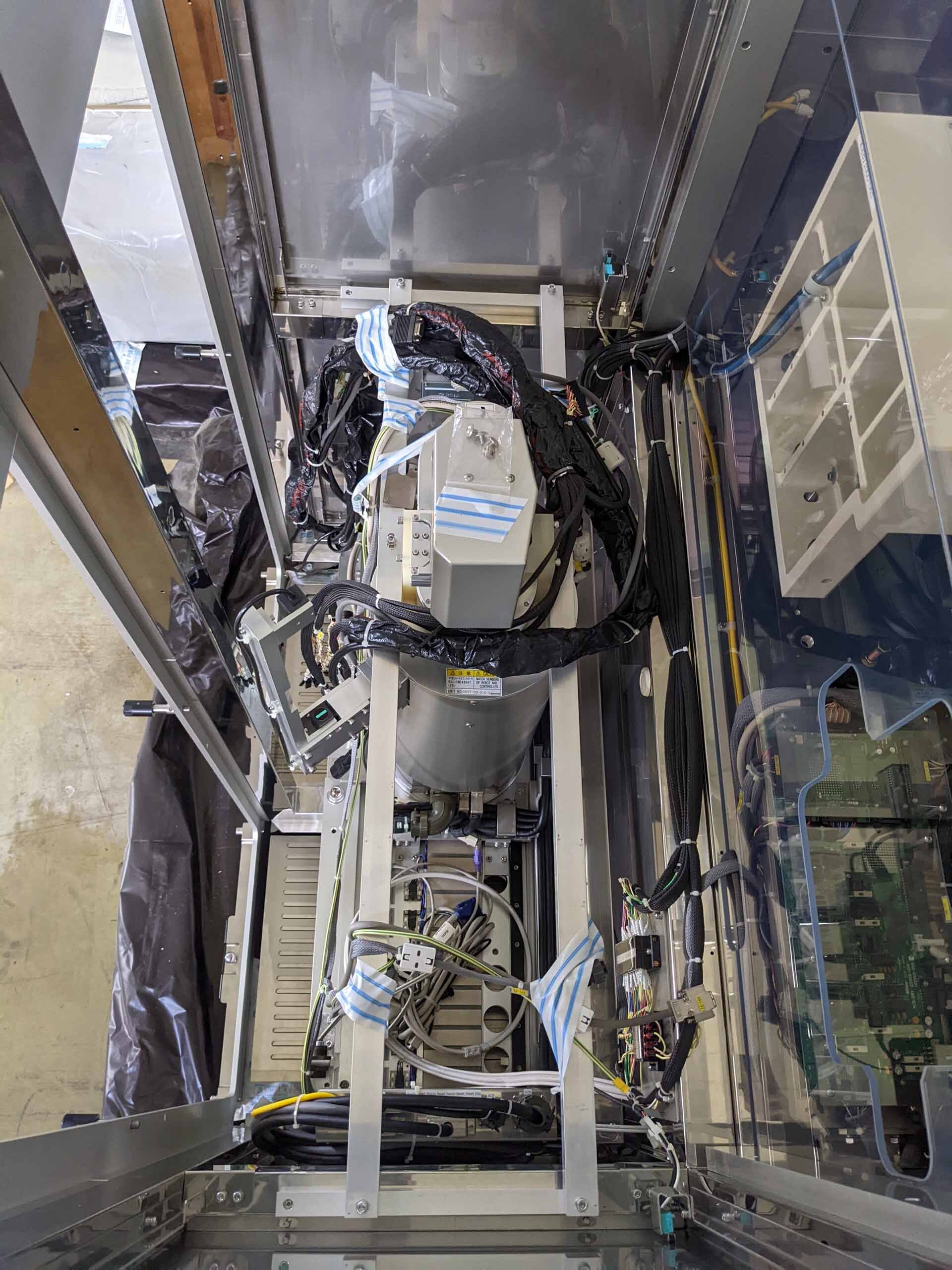

Wafer defect inspection system, 12"

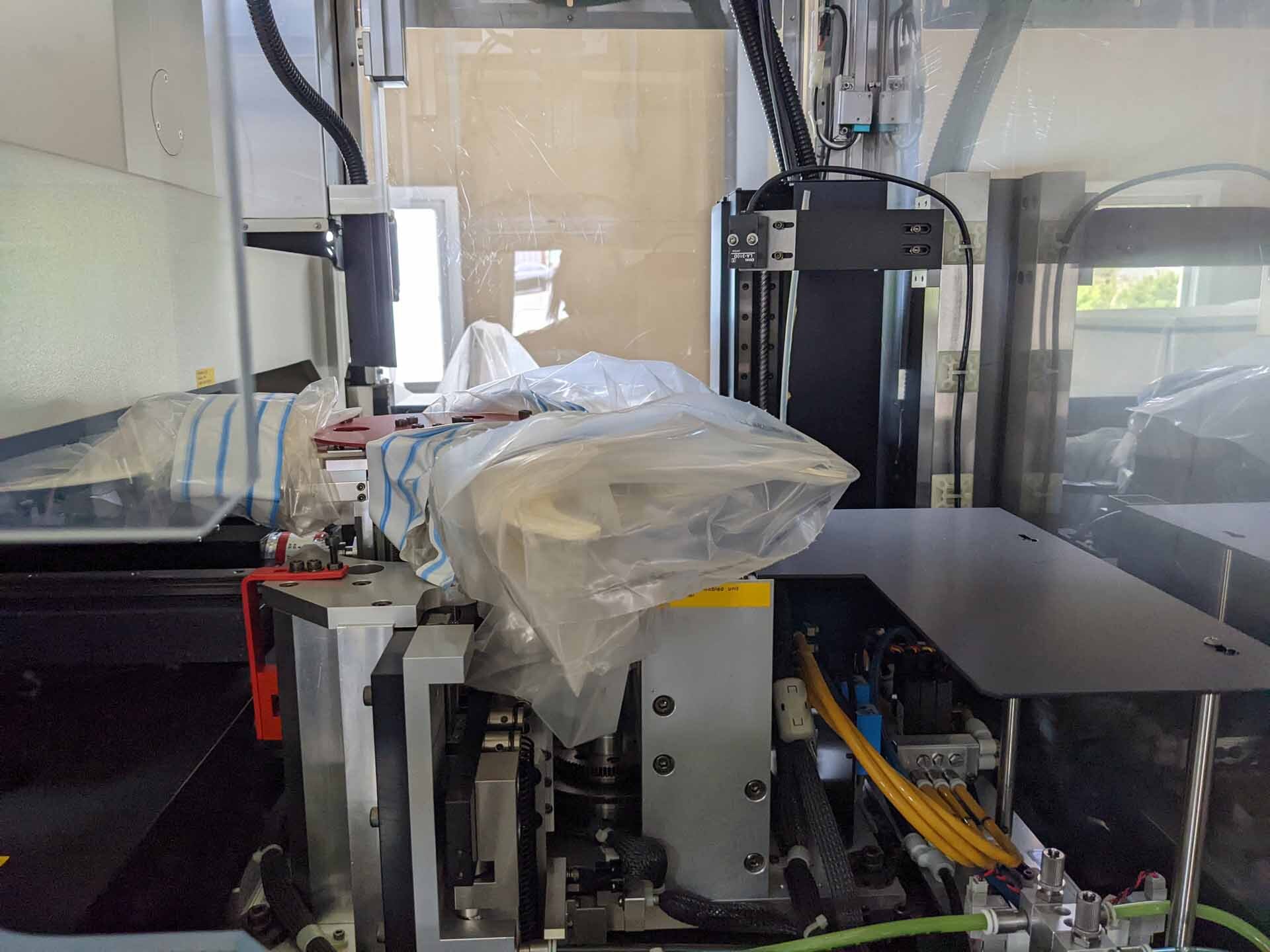

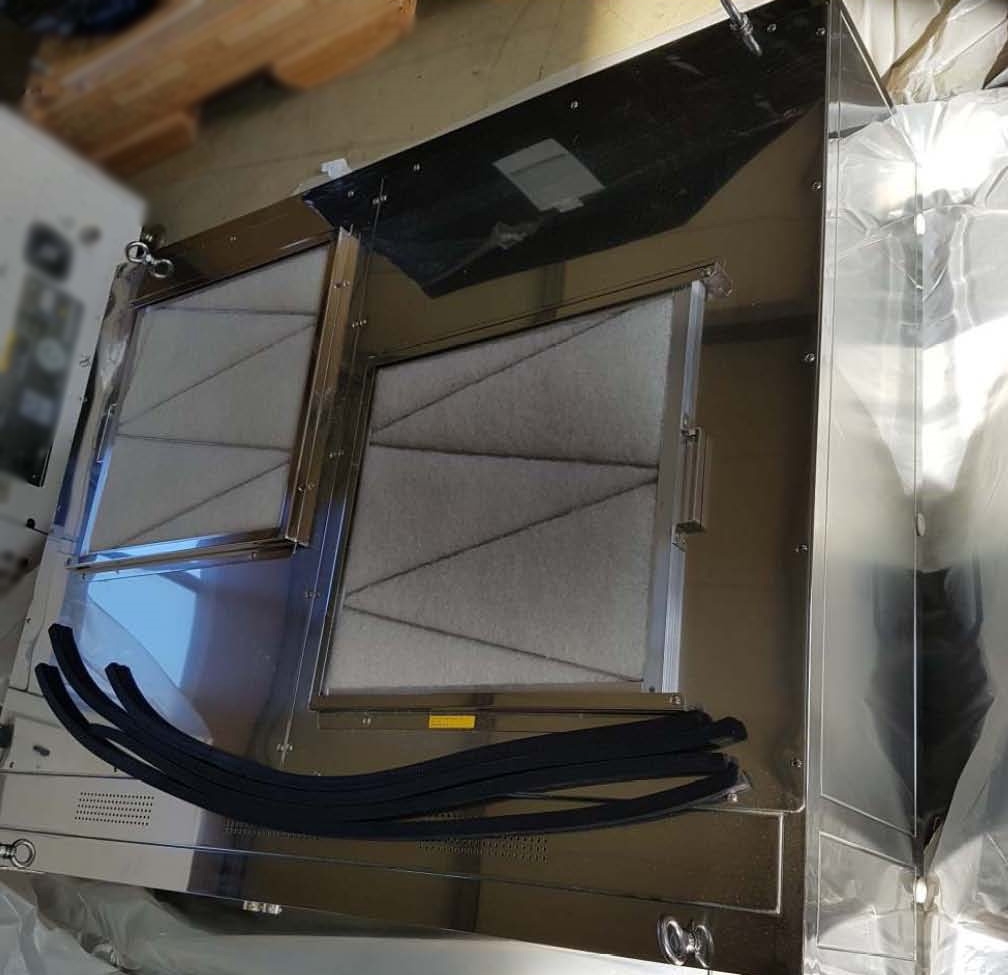

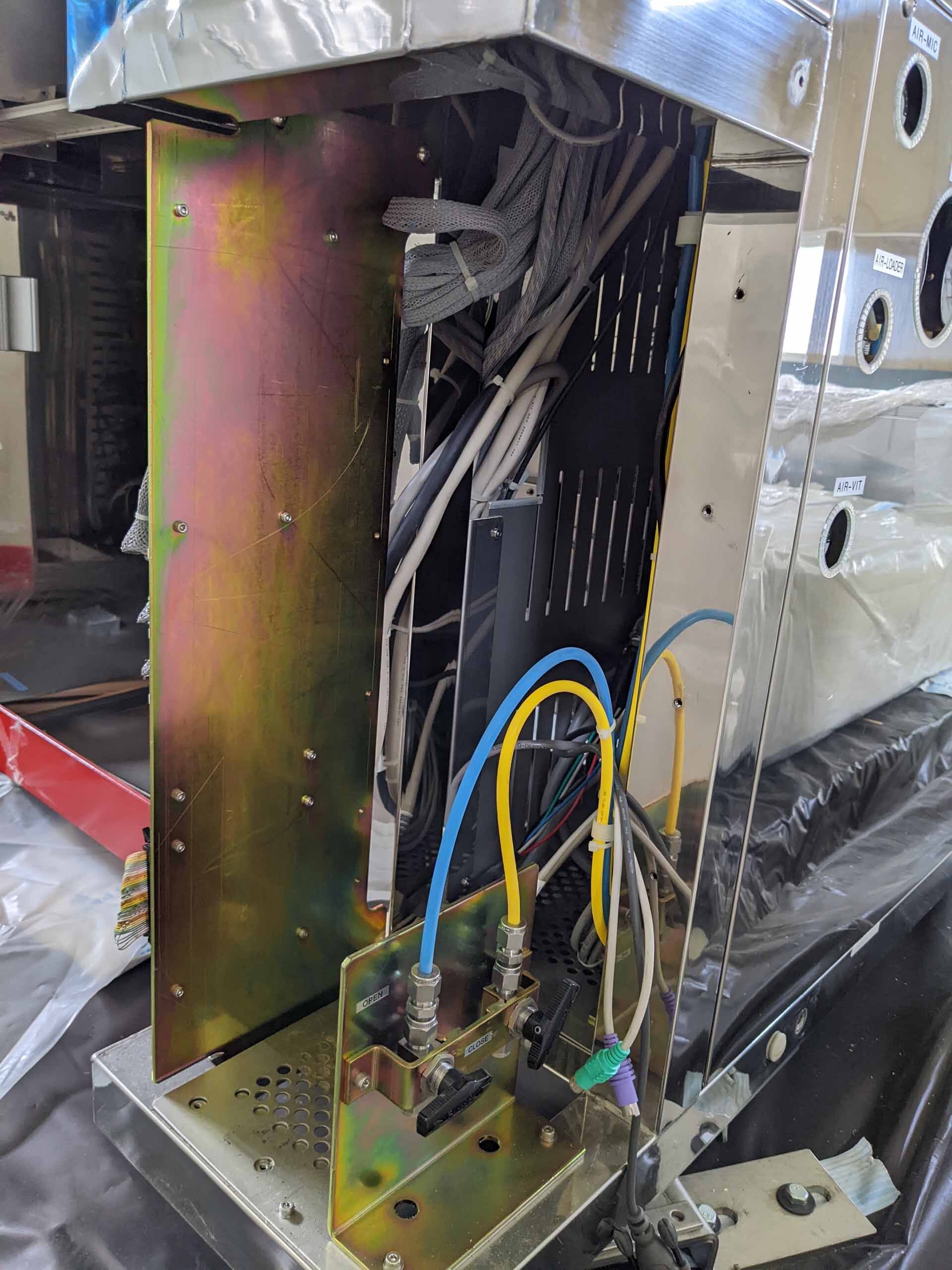

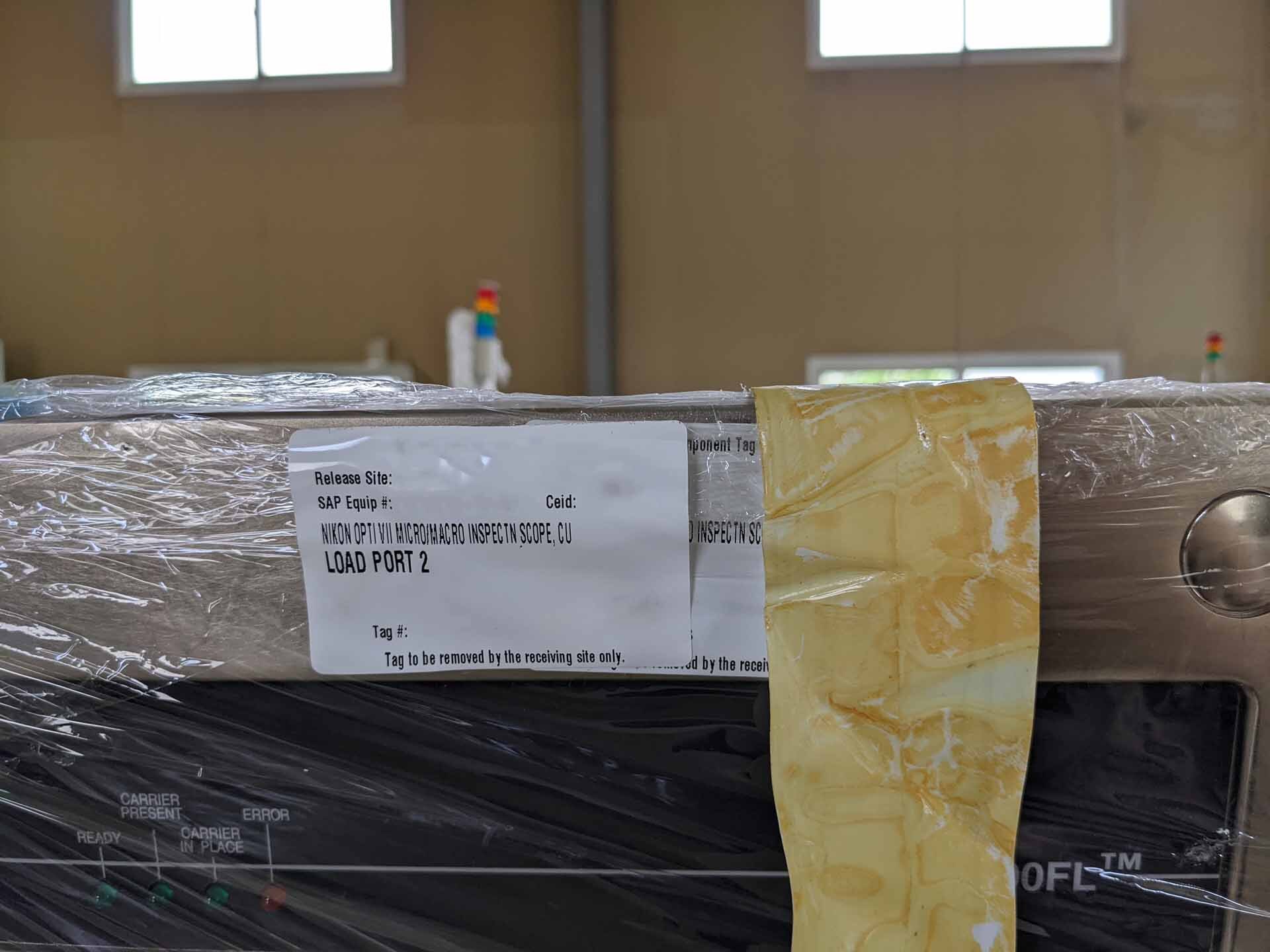

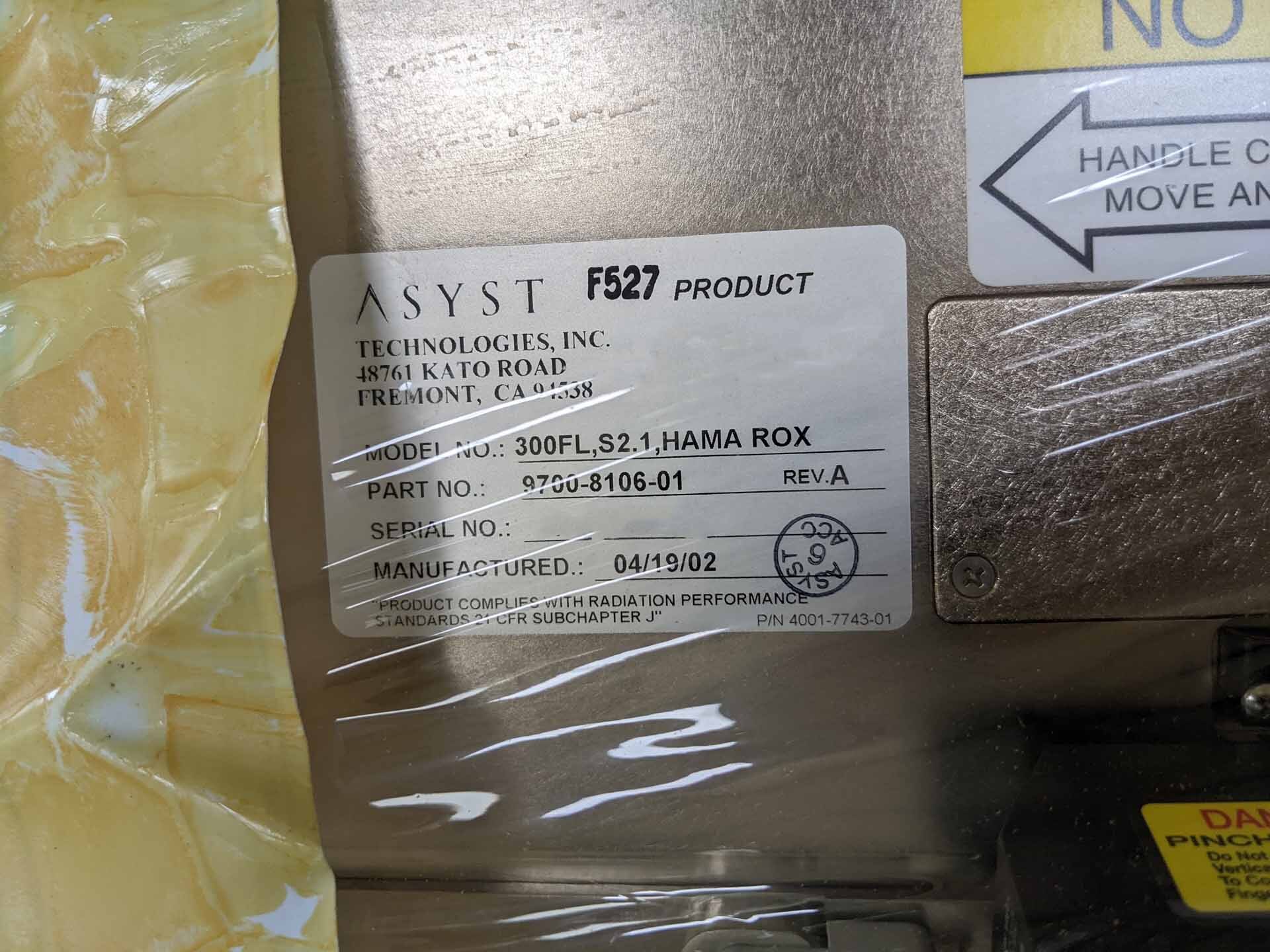

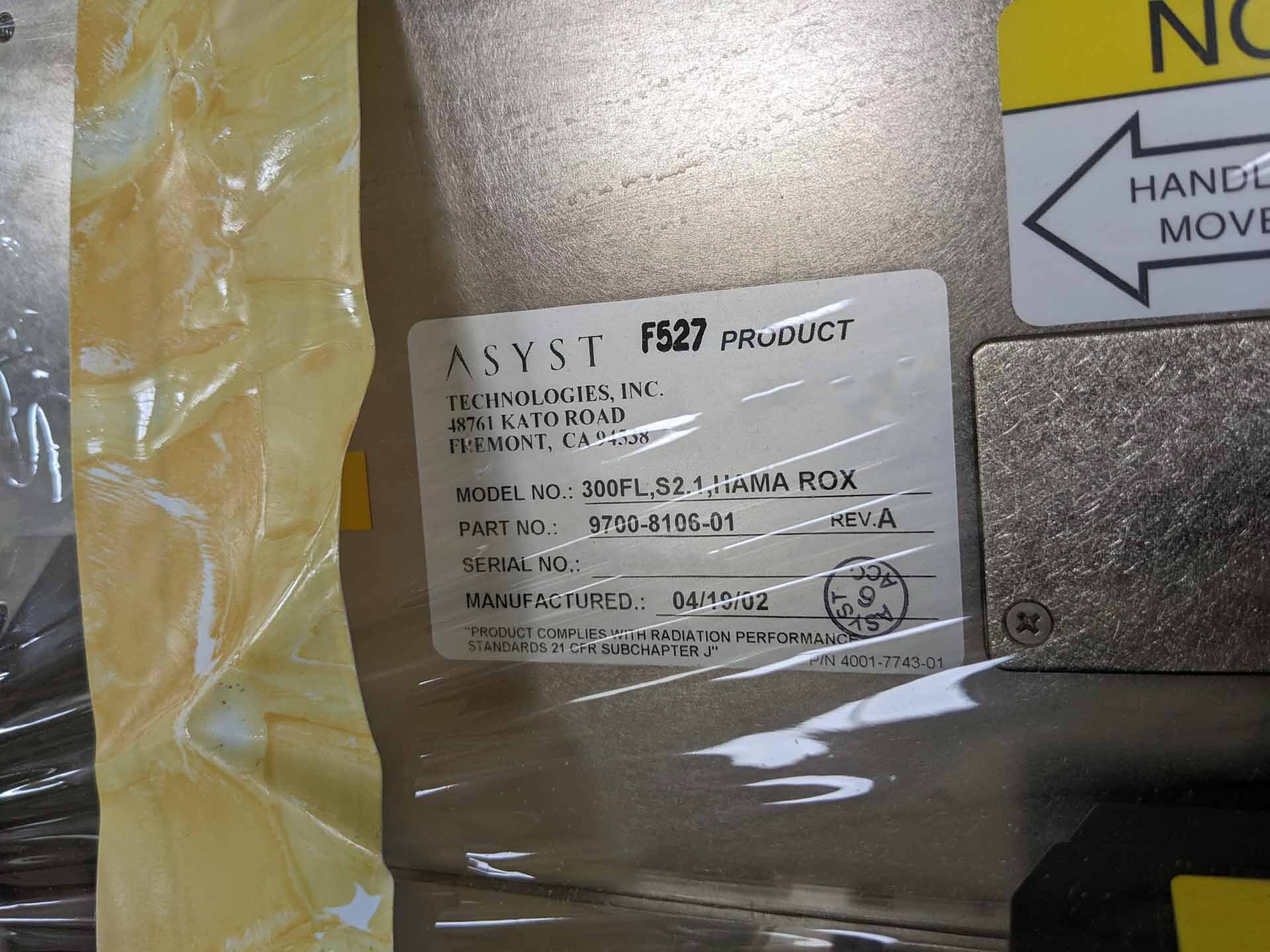

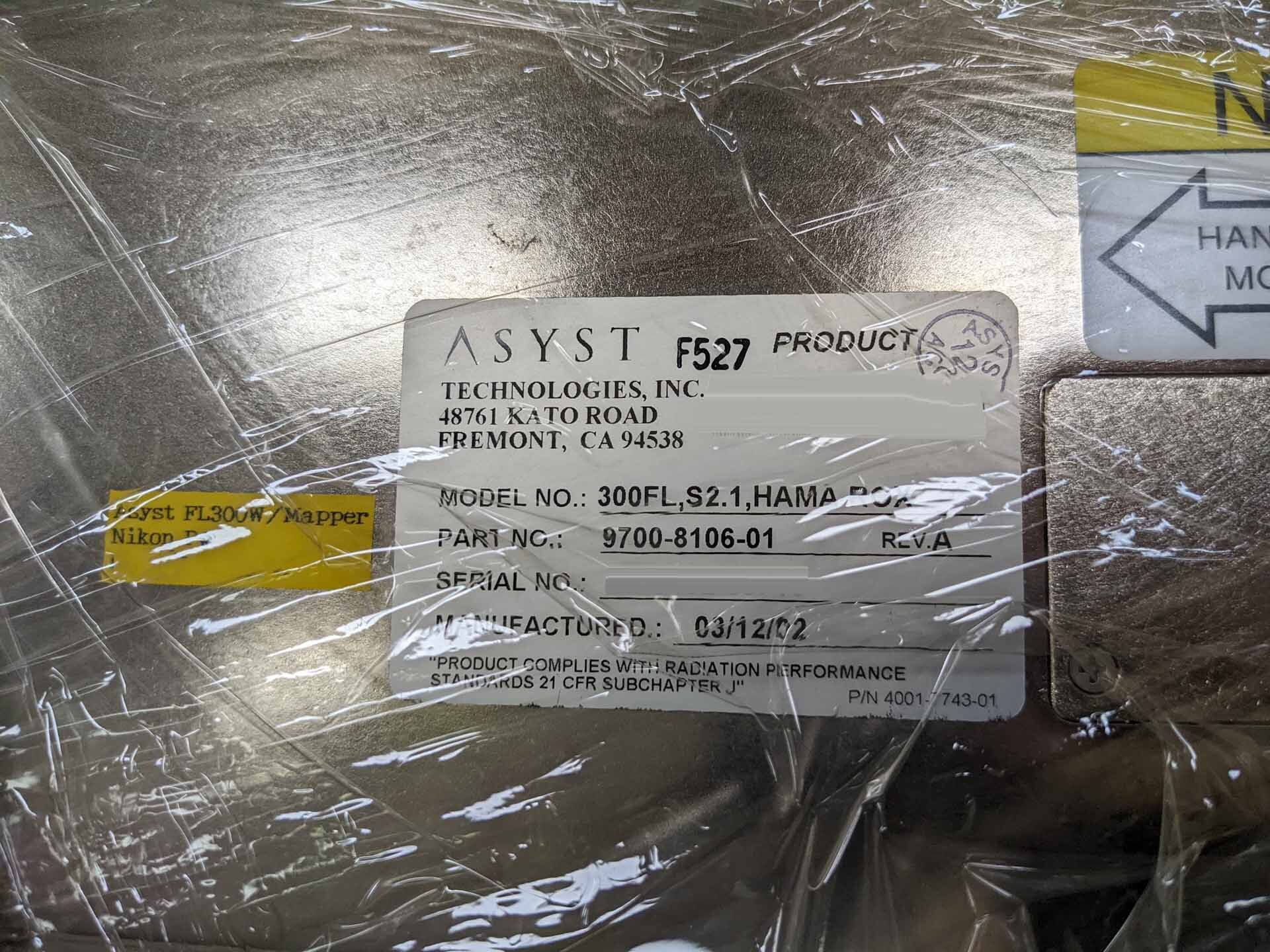

(2) FOUP Front end load ports

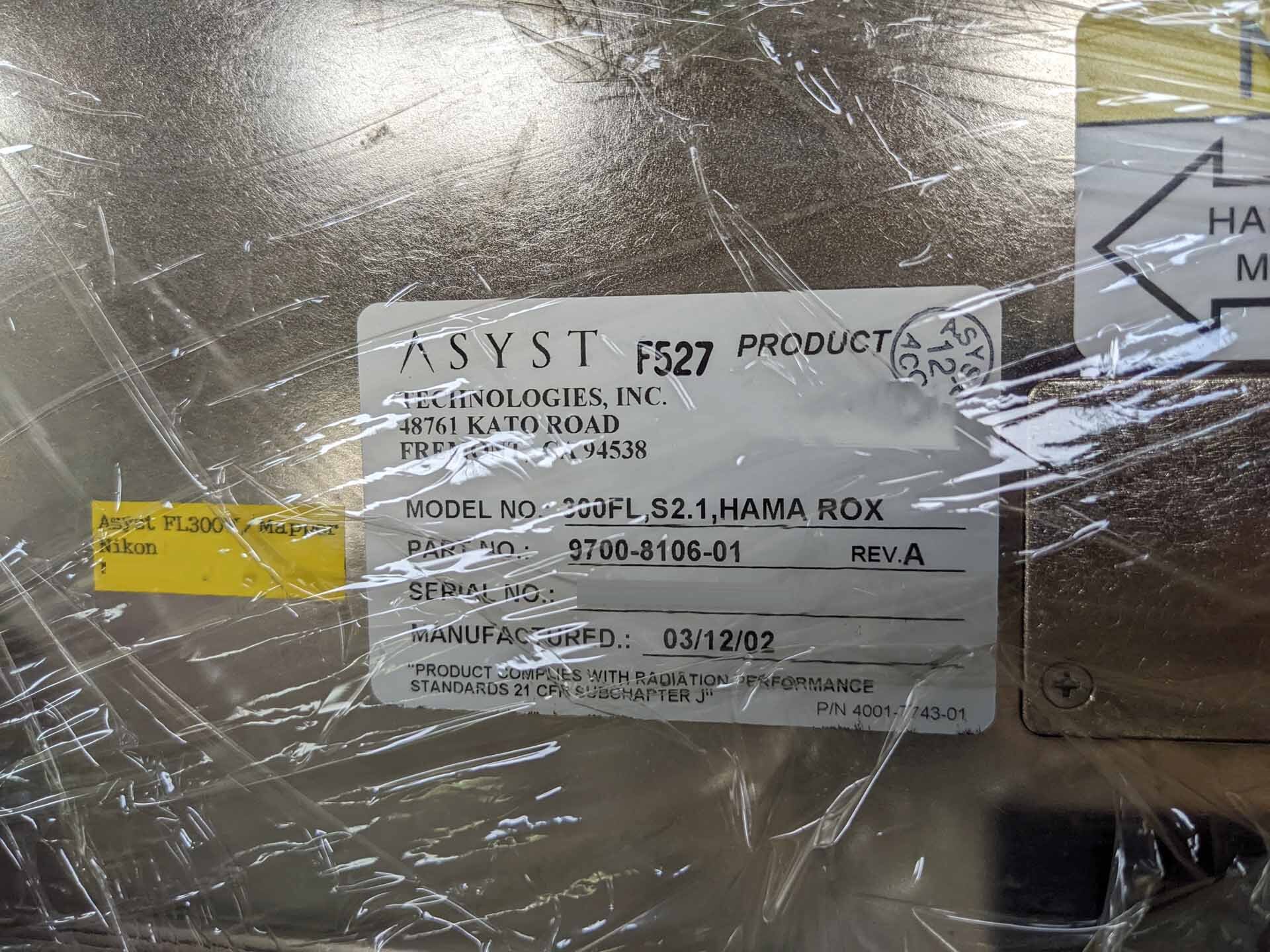

ASYST ISO Port FL300 with mapper and RF ID

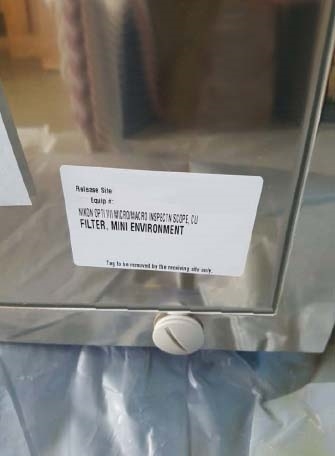

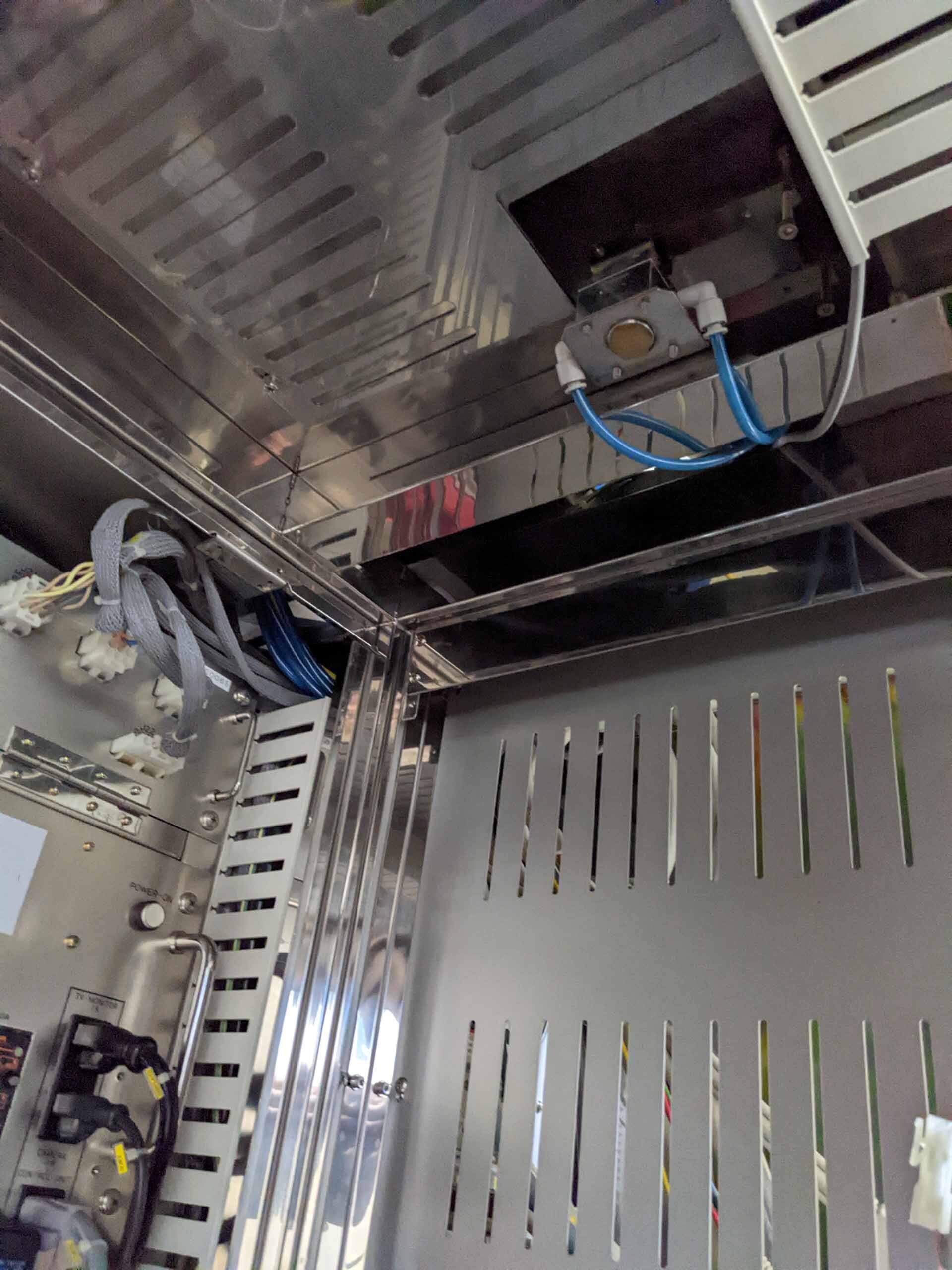

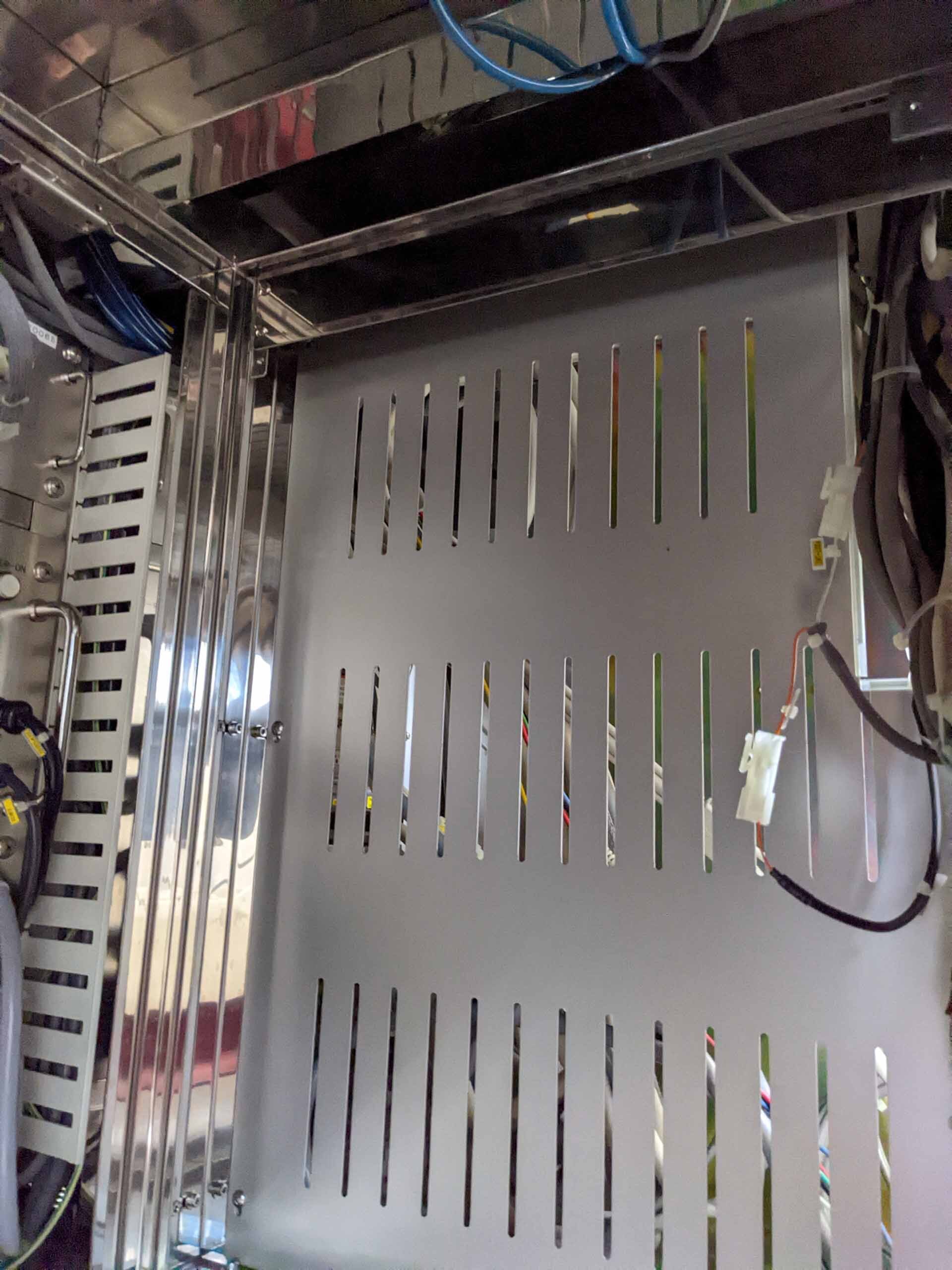

ULPA Filtration system

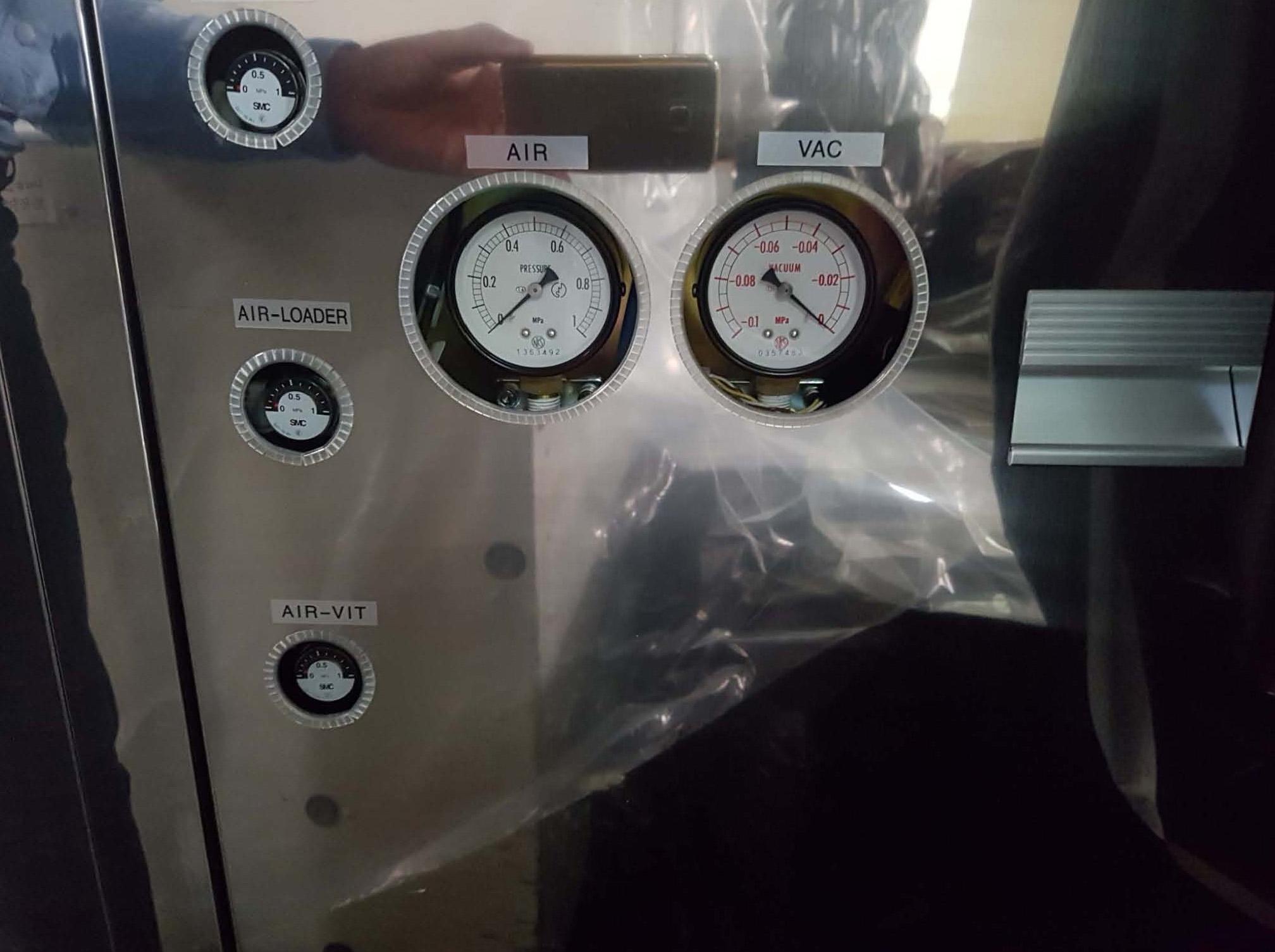

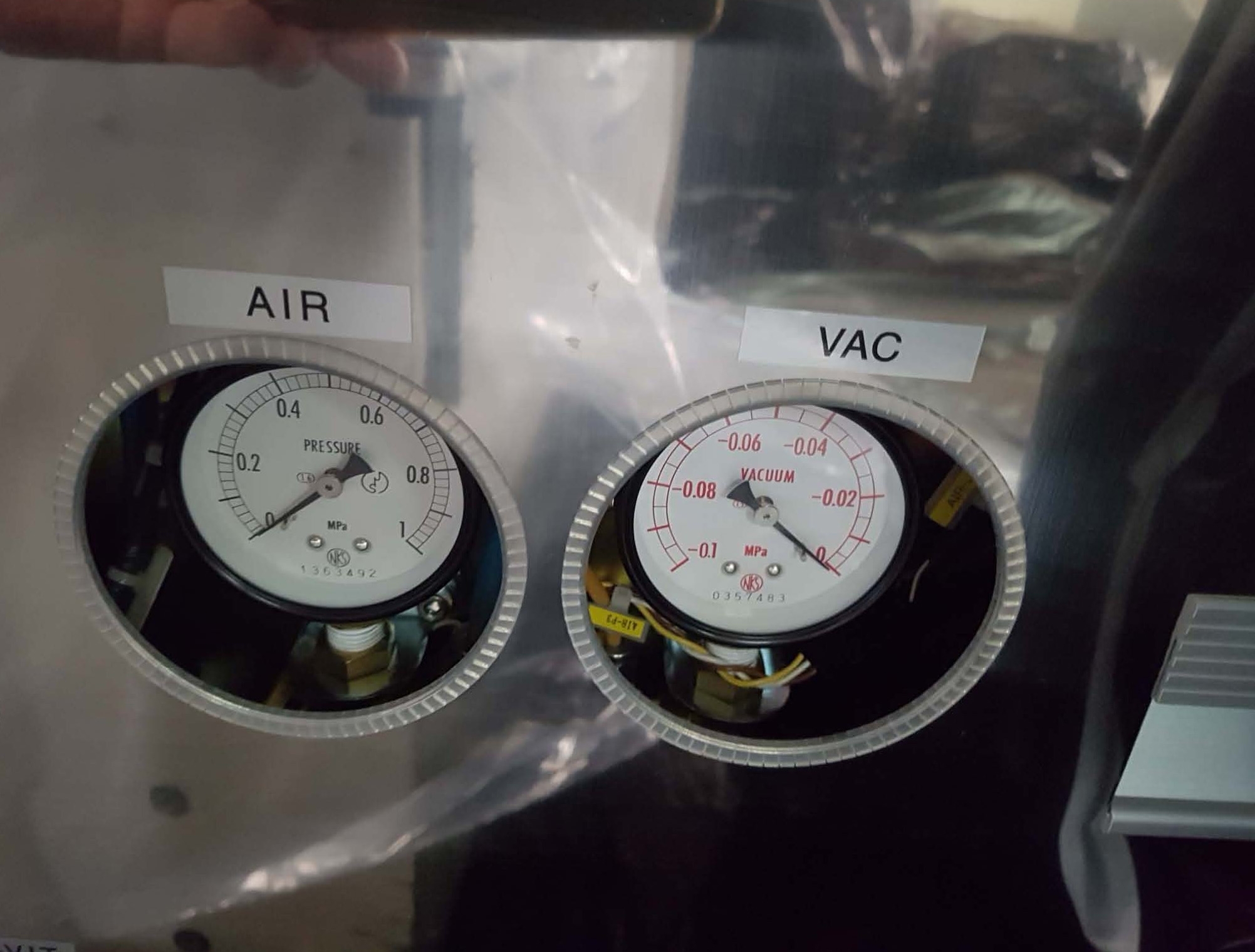

Air suspension vibration isolation table

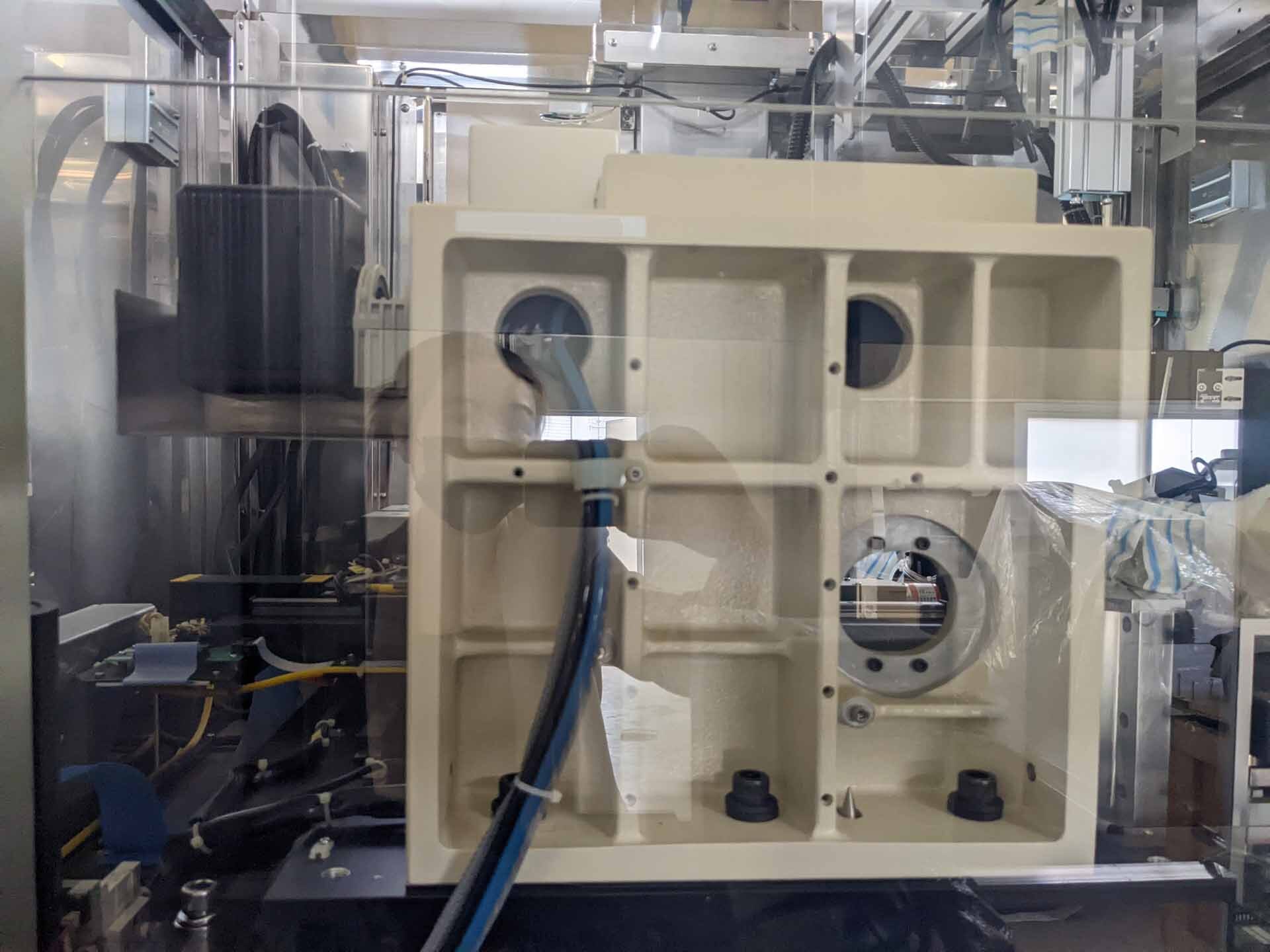

Standard microscope unit with automated control

Eyepieces: 10x

Objective lens: 2.5x

0.075 W.D. 8.8 mm

10x N.A. 0.300 W.D. 6.50 mm

20x N.A. 0.460 W.D. 3.10 mm

50x N.A. 0.900 W.D 0.42 mm

150x N.A. 0.900 W D.0.29 mm

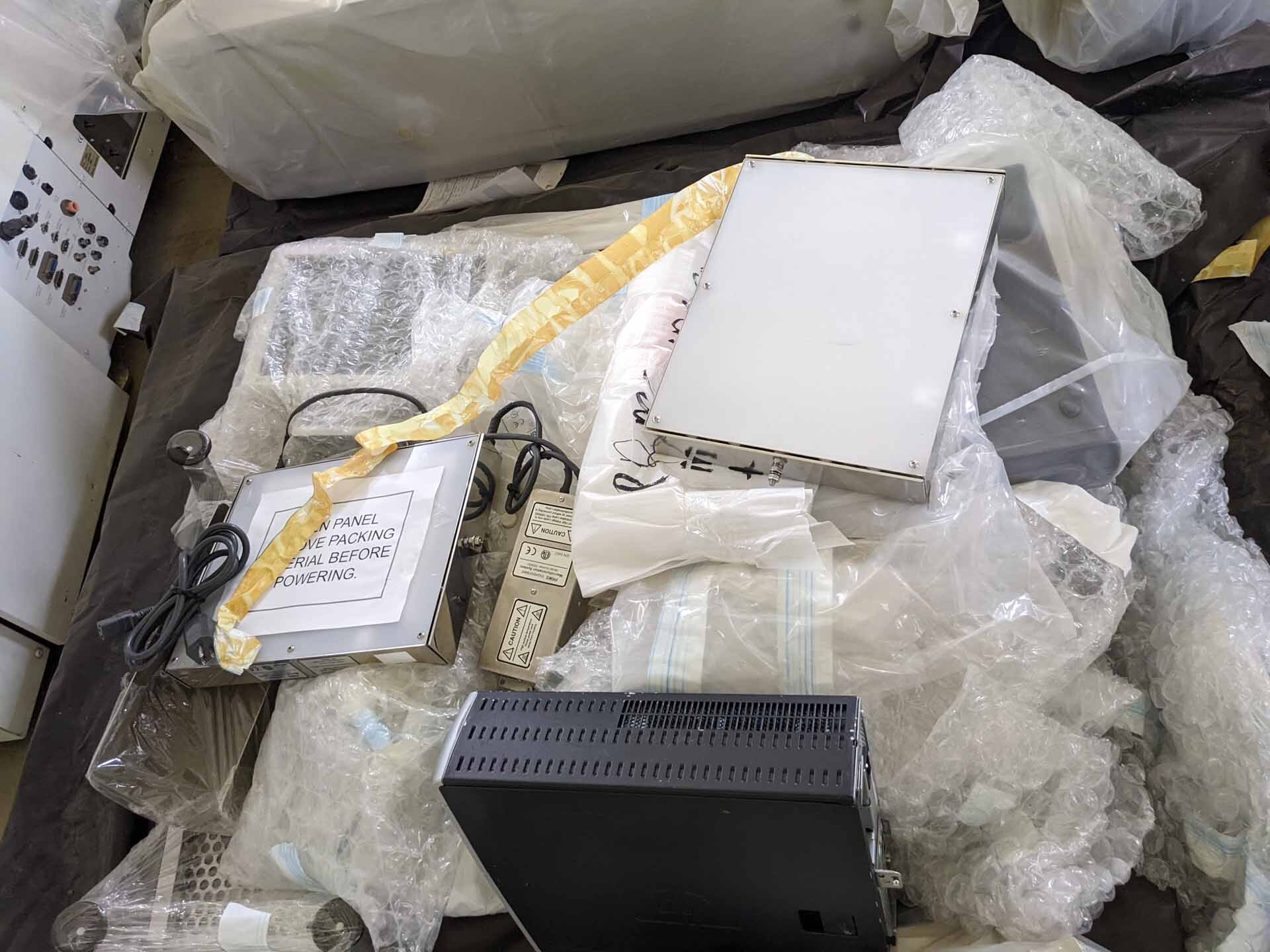

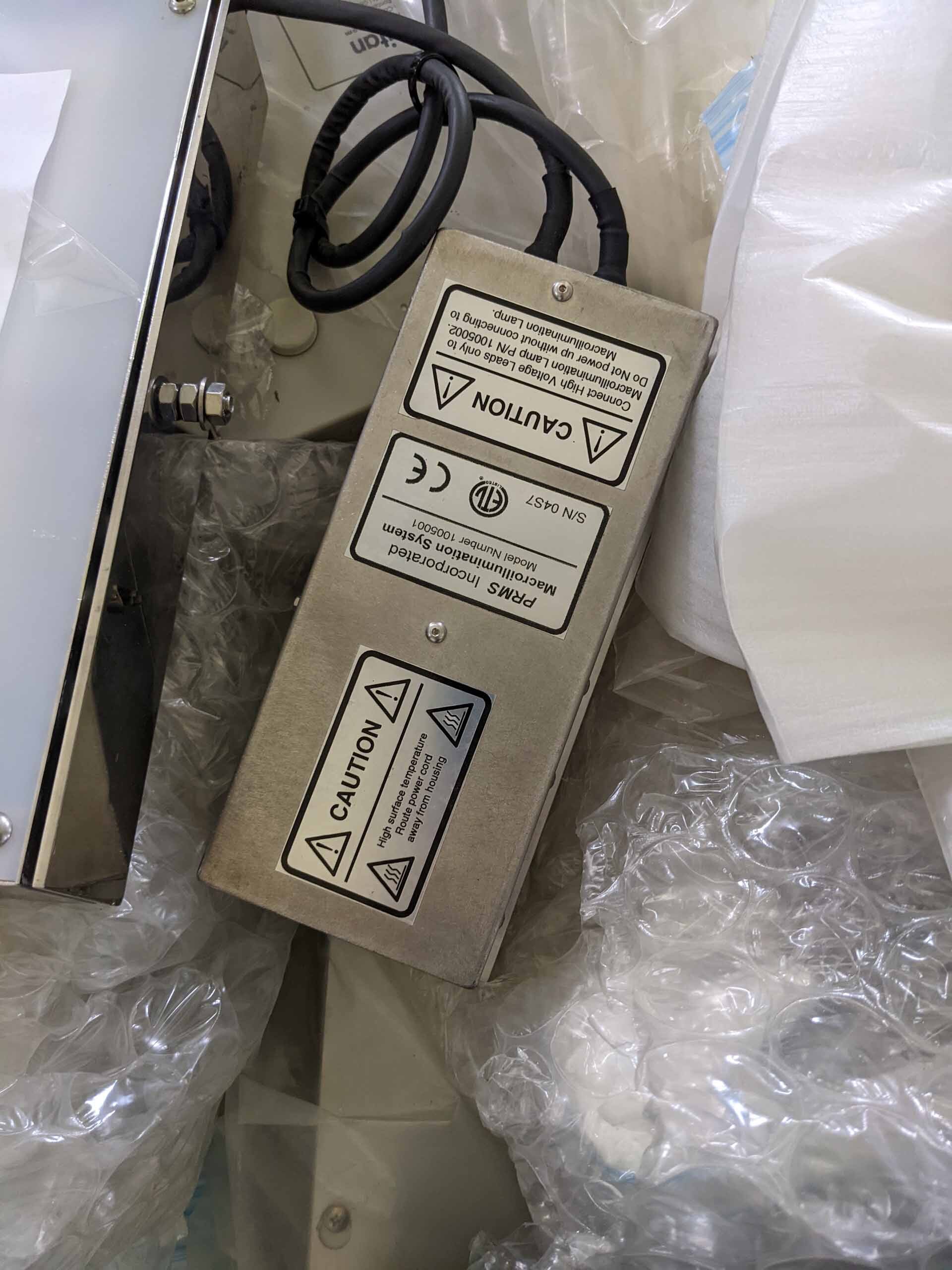

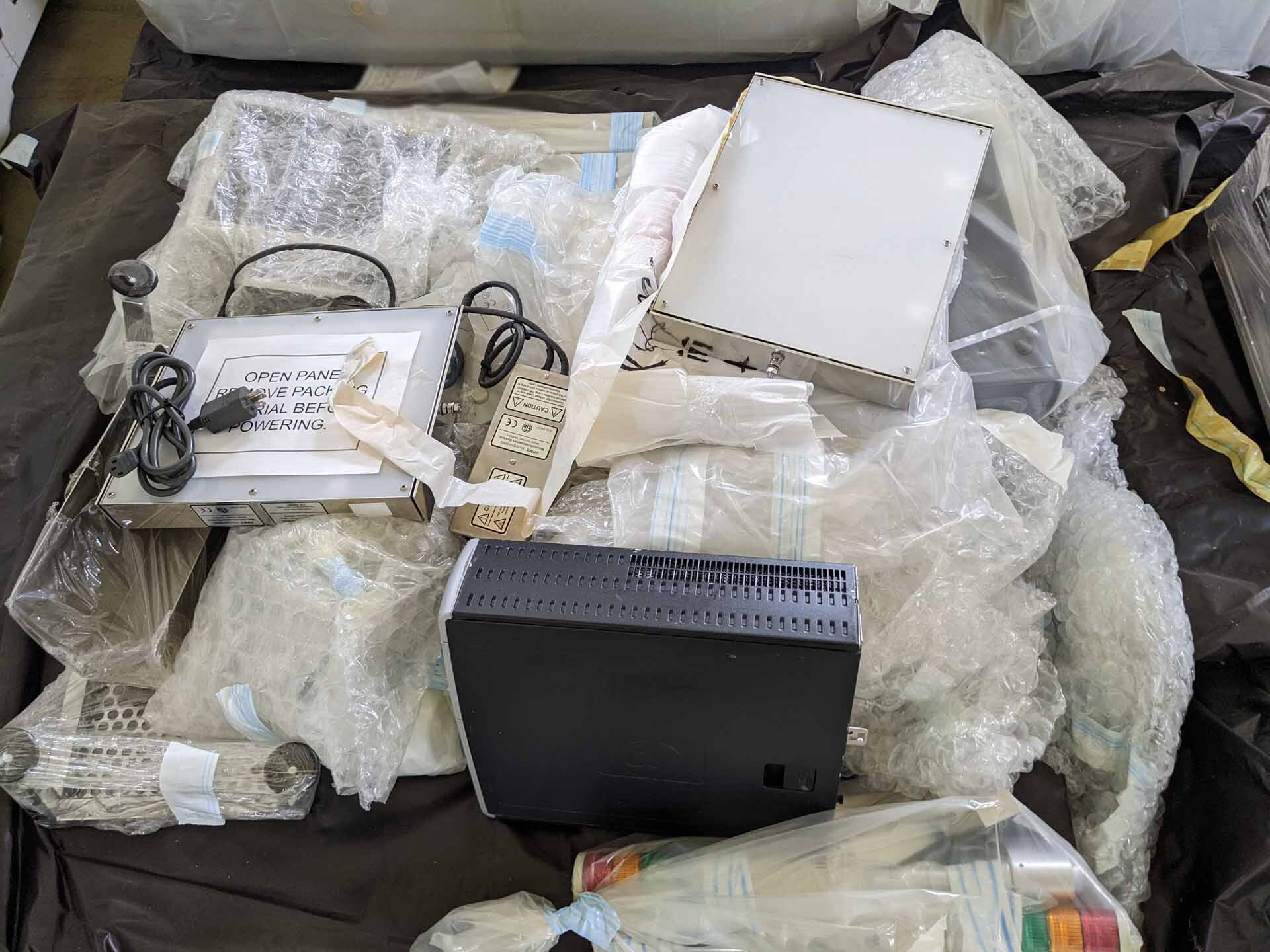

Halogen lamp house: 12 V, 100 W

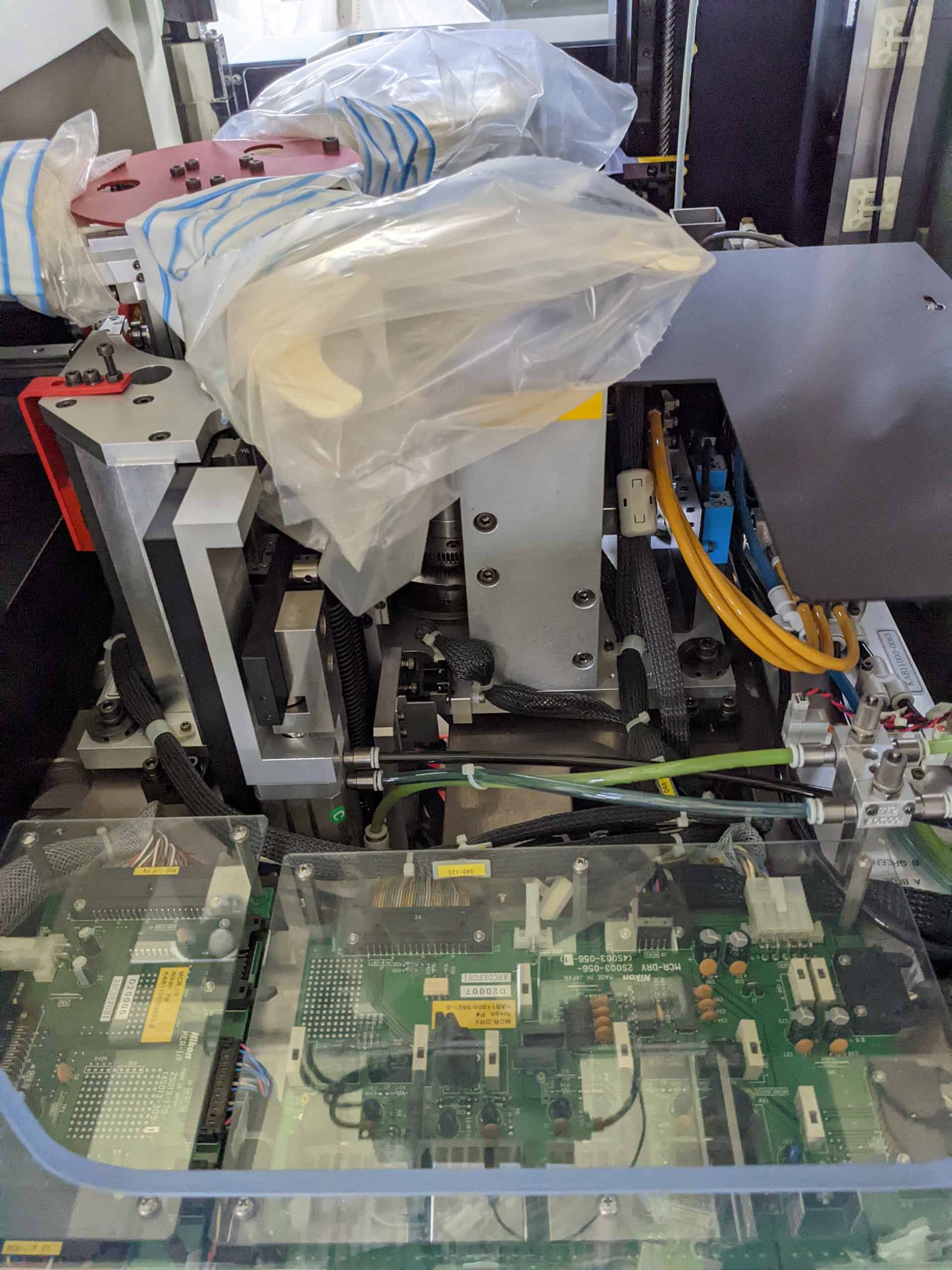

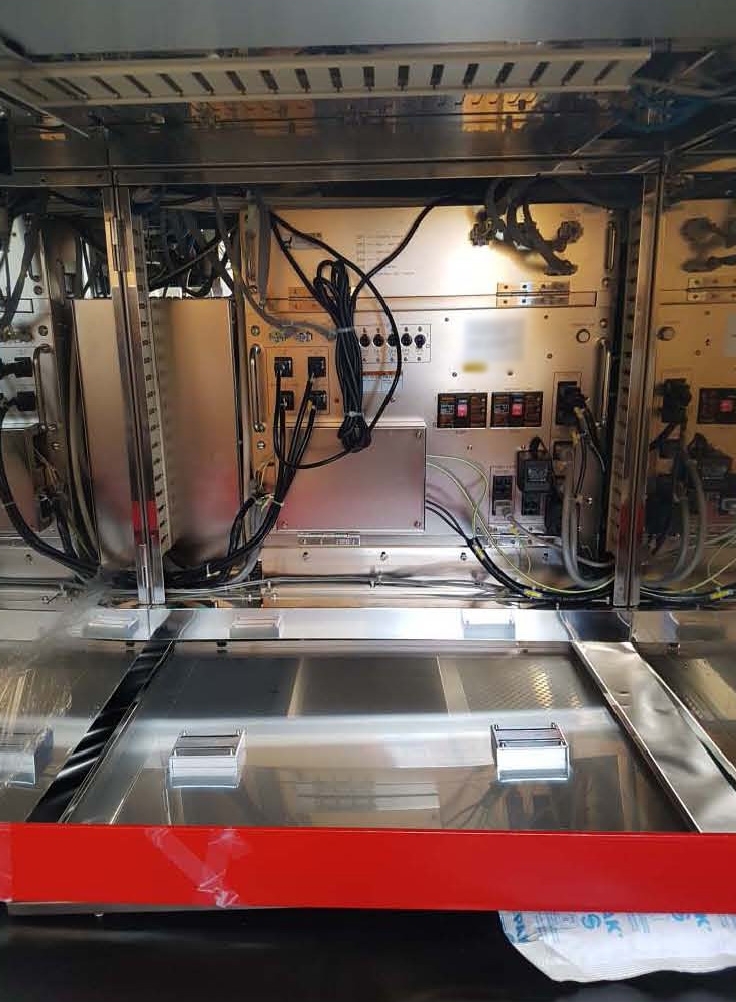

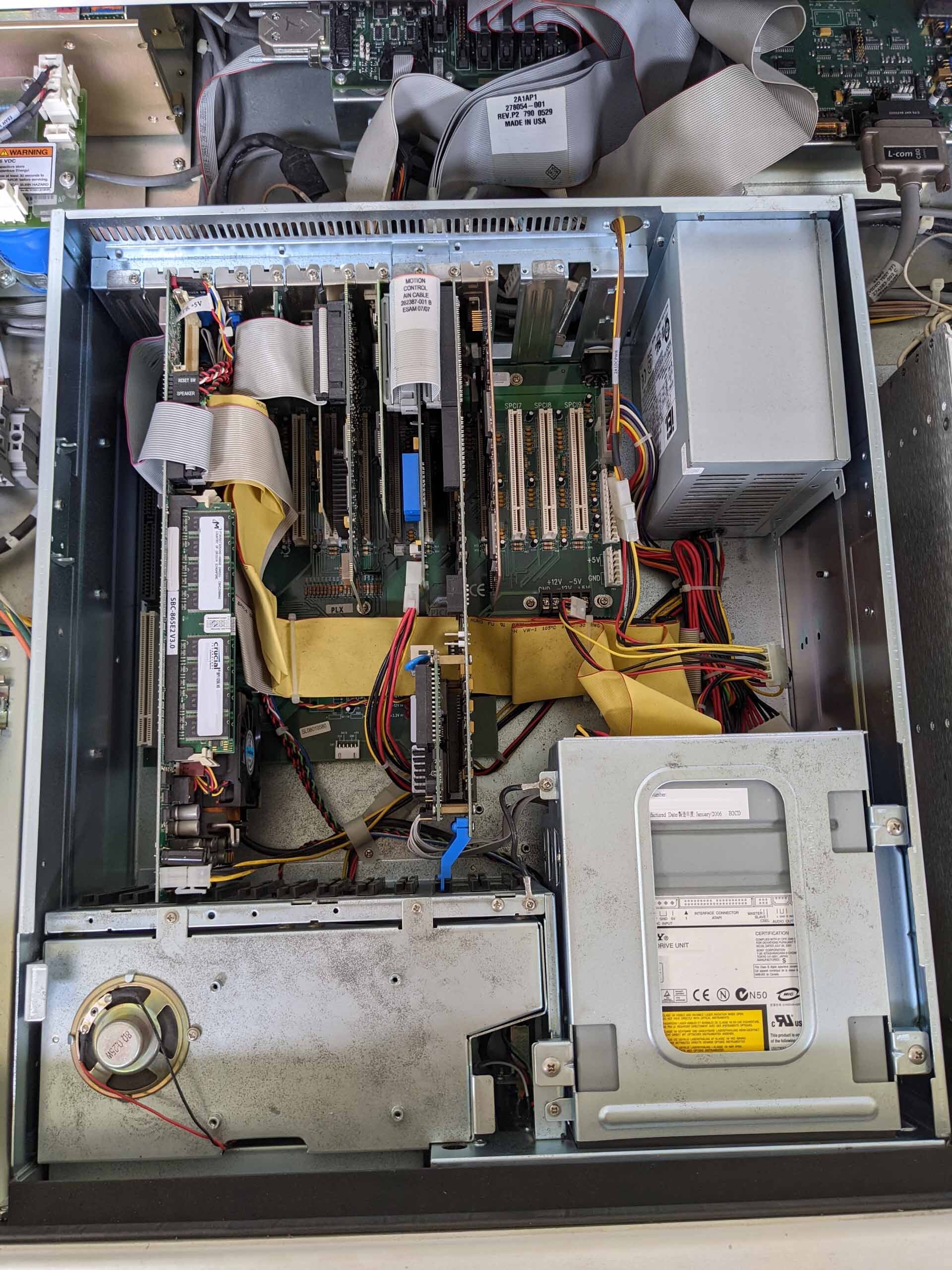

Robot controller

Ceramic robot arm

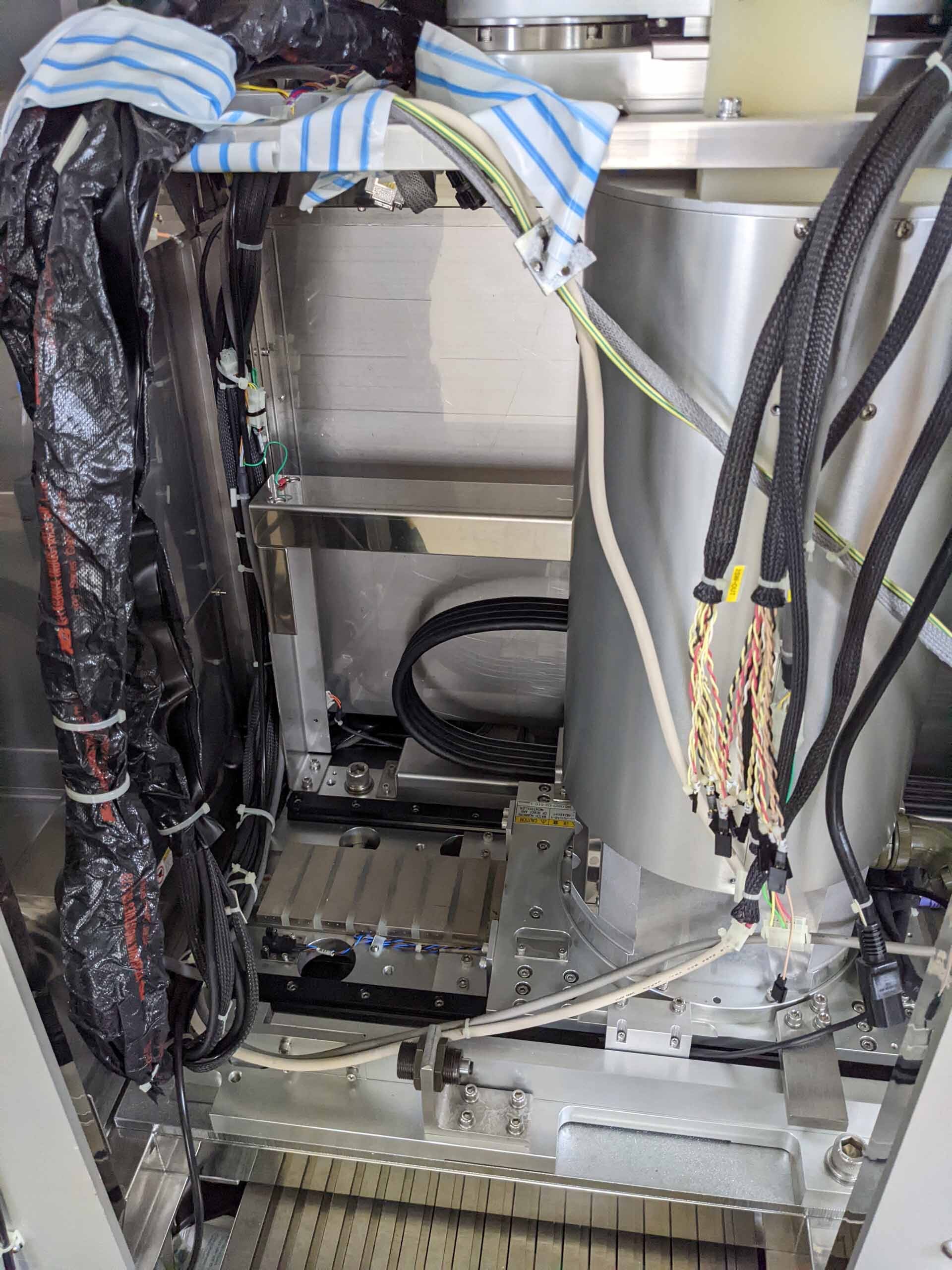

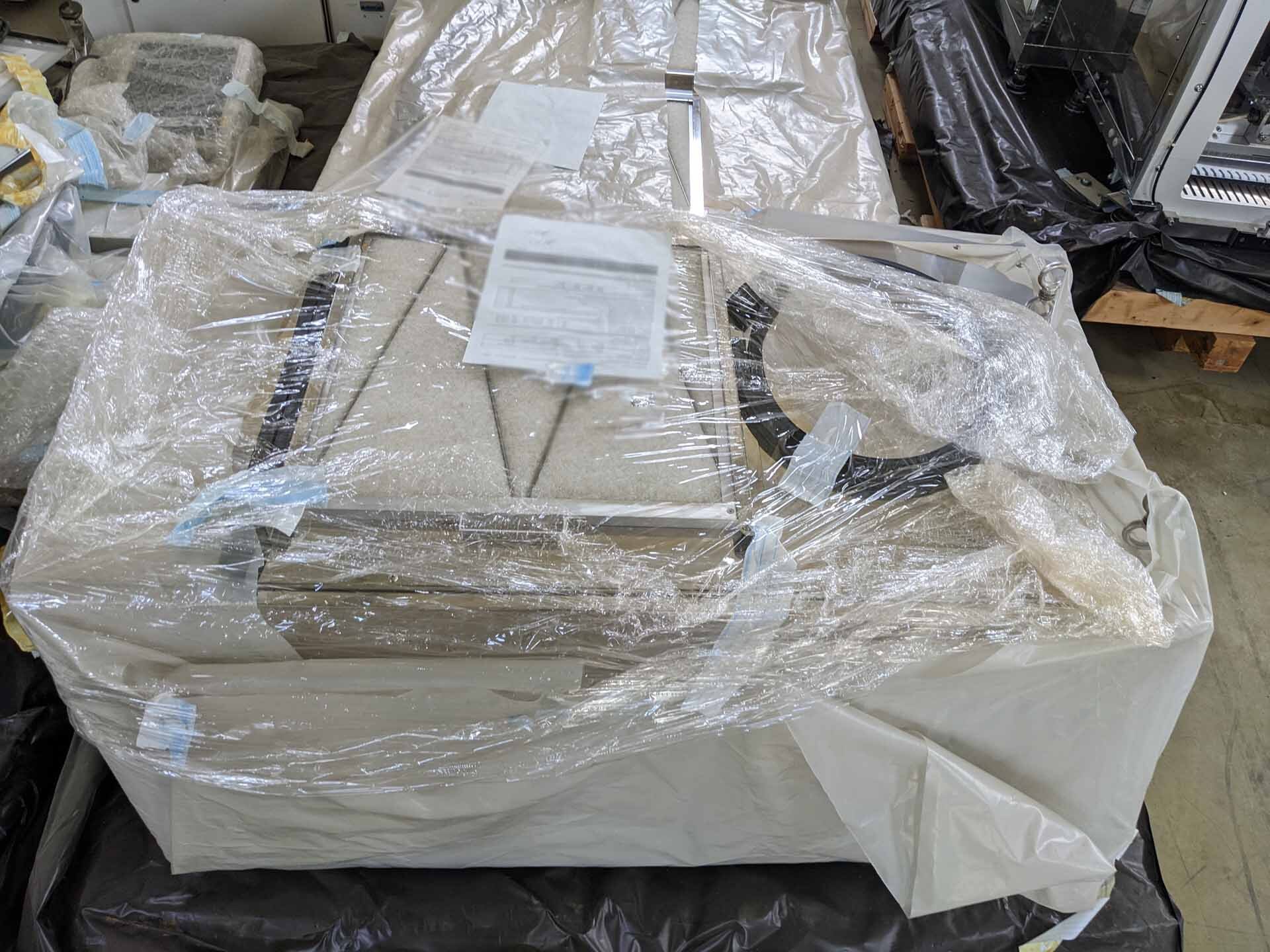

Macro unit A:

Wafer chuck

Macro movable unit

Slider assembly

Macro unit B:

Arched holder

Rotation unit assembly

Micro stage unit

XY Stage / Chuck

XYZ Drive unit

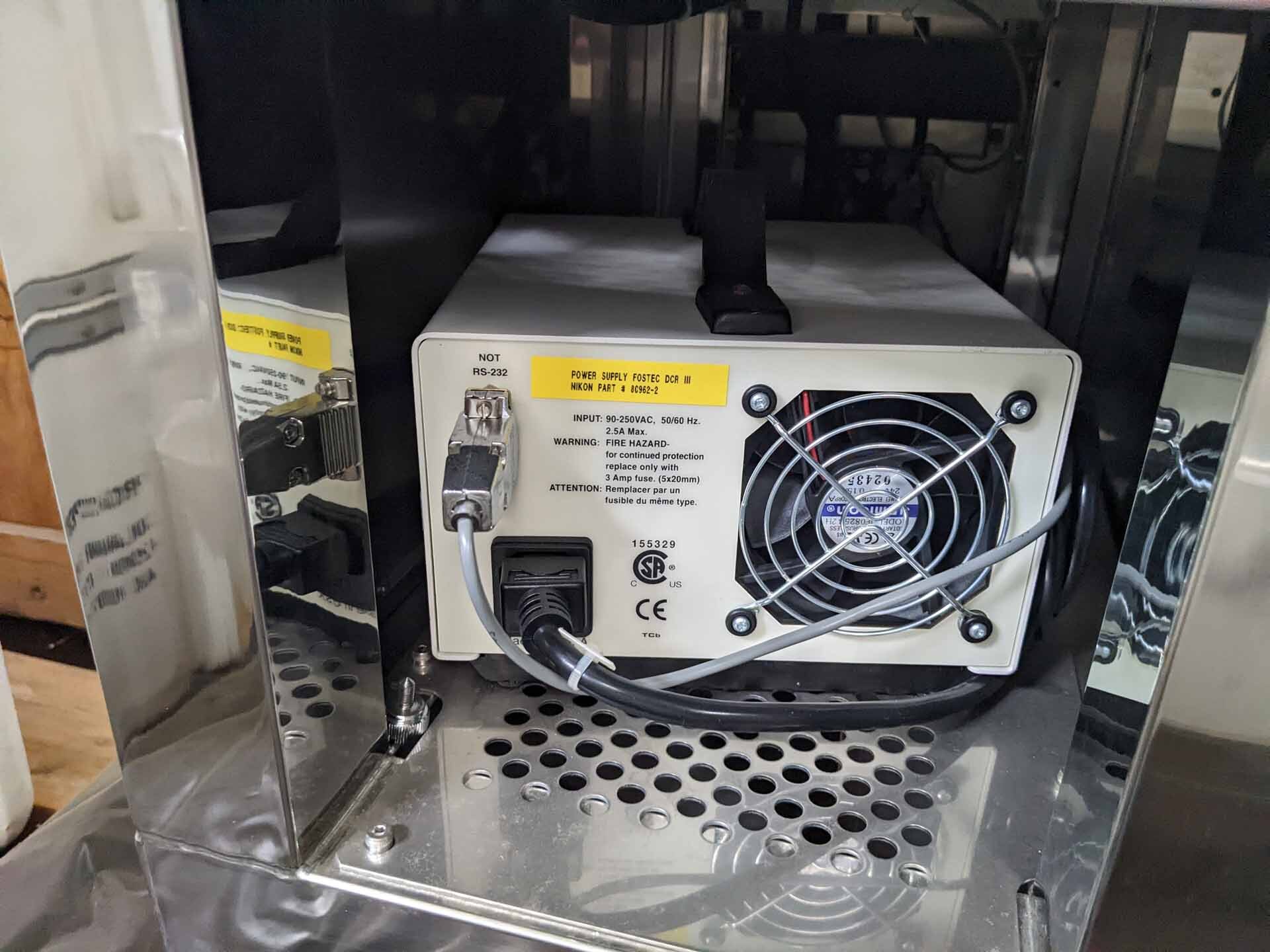

DART Controller: Image archiving and defect review

LCD Display

Keyboard / Trackball

Image capture board:

Integral technologies video card

SONY DXC- 9XX/MD Camera.

NIKON Optistation VII is a flexible, high throughput mask and wafer inspection equipment that provides rapid and automated inspection of both masks and wafers. This system offers superior accuracy in terms of defect detection, with the ability to detect patterns as small as 0.2 to 0.8 microns. It also offers a wide range of versatility for inspecting a variety of different materials, including photomasks, lithographic masks, and wafers. The unit operates using a high speed xenon strobe light source to illuminate the sample, and a CCD camera to capture the image. The imaging machine can detect submicron differences as well as signals well beyond the visible light spectrum, which allows the tool to accurately inspect for defects and sub-micro structures. Its 4K pixel CCD array enables extremely fine inspection resolution, and the asset has powerful magnification capabilities ranging from 5x to 2500x. The model has a large 12x12 inch inspection area, enabling it to cover up to a dense area of the material quickly and non-destructively. Its constant-depth focus assures high accuracy and consistency throughout, so that images are consistently sharp and clear. Additionally, with no human involvement needed, the equipment can perform automated scanning and analysis without interruption. Moreover, Optistation VII comes equipped with advanced software for automated feature inspection. It has a powerful defect detection engine to detect particles, flaws, minute defects, and irregularities. This software is also equipped with powerful programming capabilities, enabling the user to create automated sequences to inspect multiple types of features. NIKON Optistation VII is designed to provide automated, reliable, and high accuracy inspection of both masks and wafers. With a wide range of versatility, advanced software capabilities, and superior accuracy, this is an ideal choice for inspection applications that require a high degree of precision.

There are no reviews yet