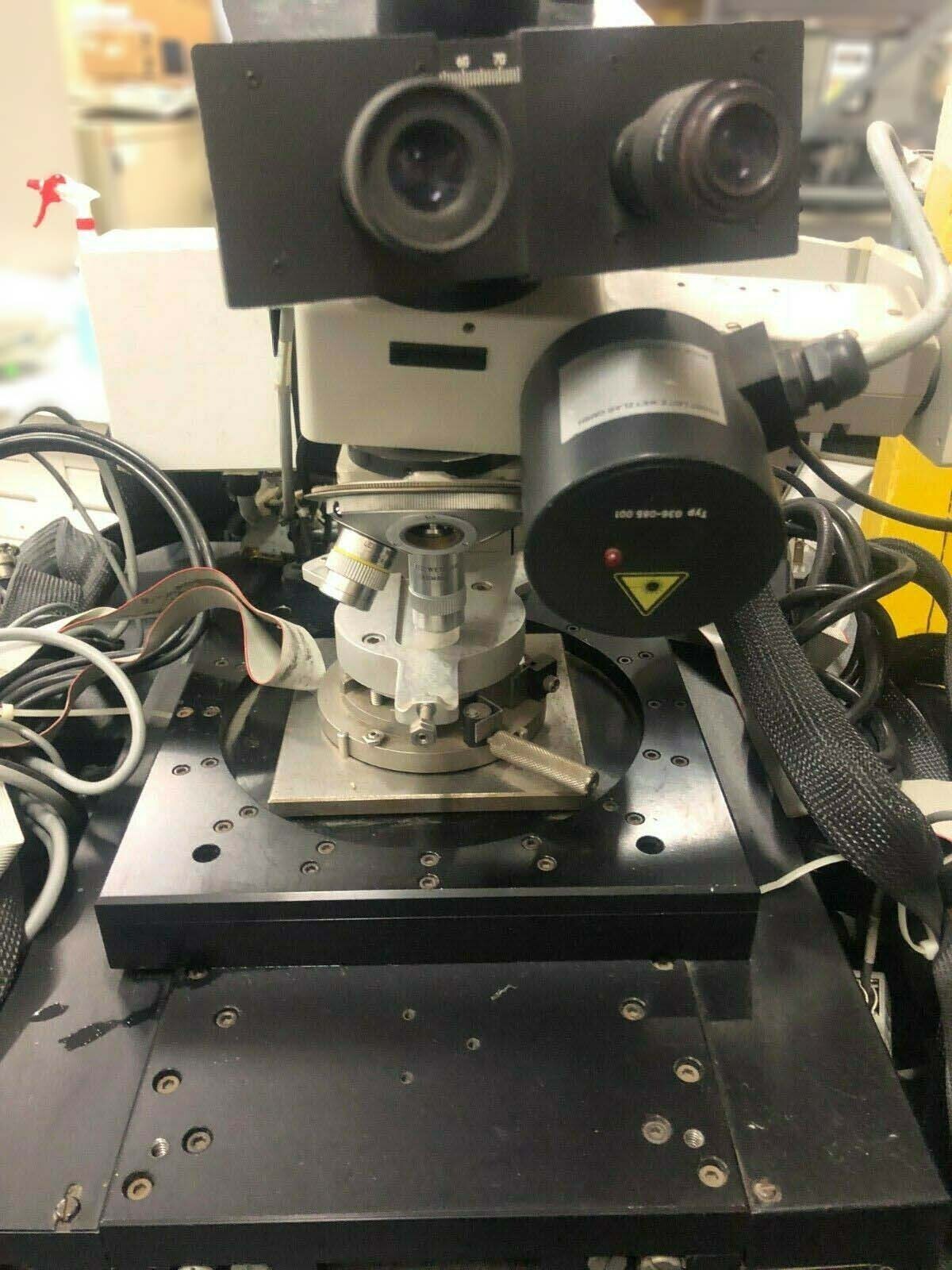

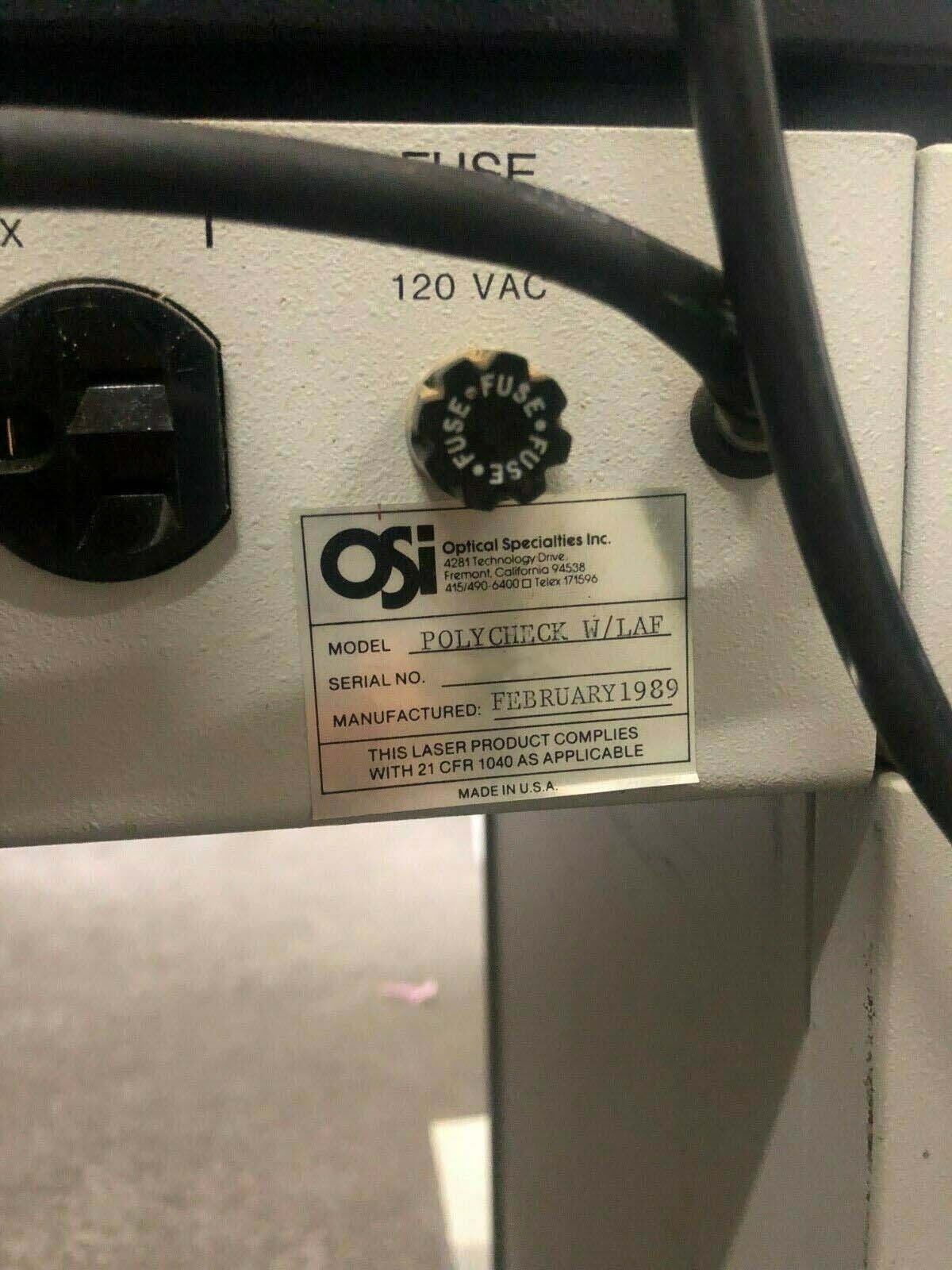

Used OSI POLYCHECK W-LAF #9329316 for sale

URL successfully copied!

Tap to zoom

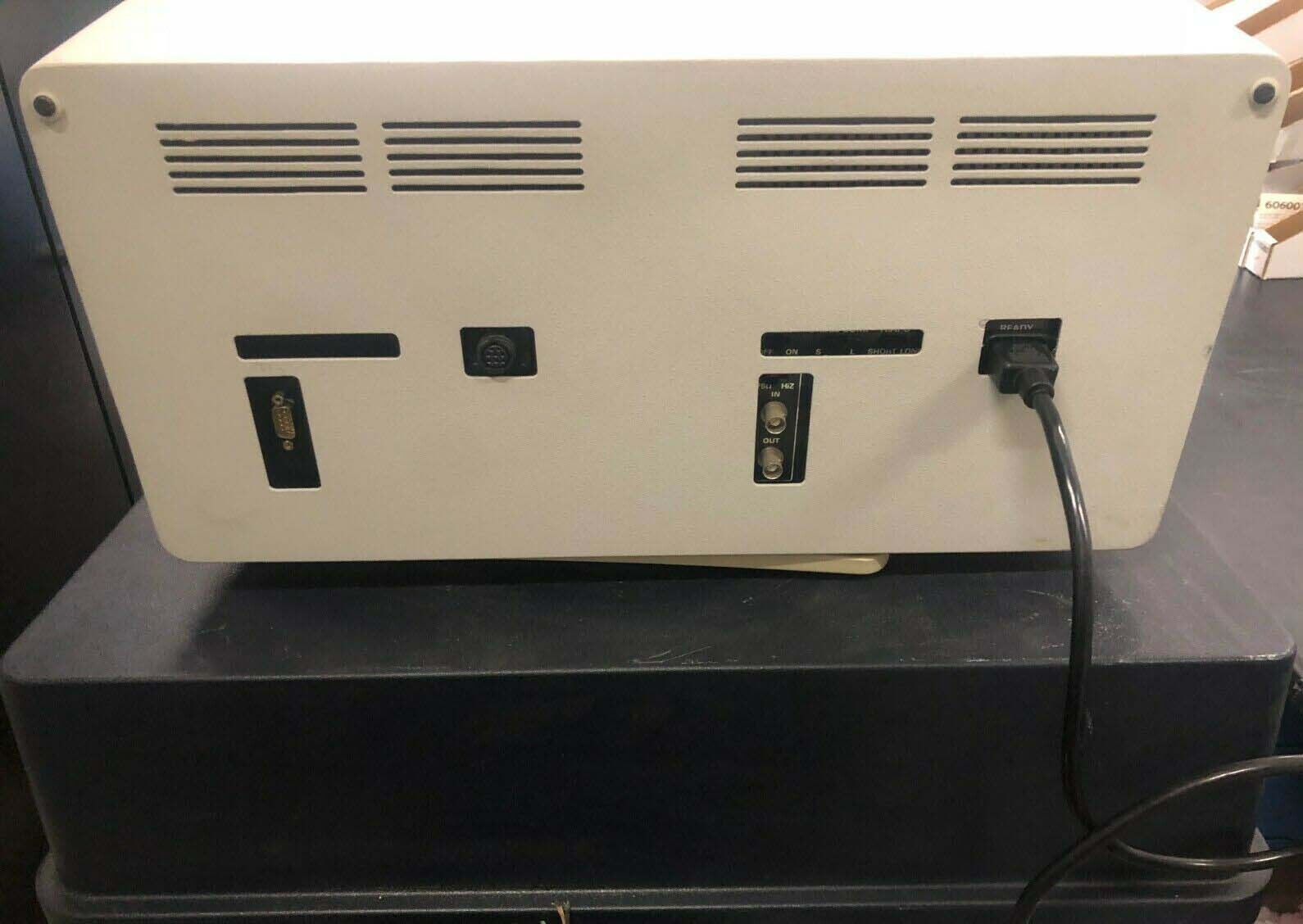

OSI POLYCHECK W-LAF is a mask and wafer inspection equipment developed by OSI Opto Electronics. It is a fully automated system designed to reduce time and effort in finding defects in photomasks and wafers. The unit works by examining images of the wafers and photomasks to identify defects, and then sorting them out into classifications beforehand. Using an optical laser projection machine, POLYCHECK W-LAF is capable of detecting extremely small particles and defects, such as particles that are smaller than 25μm in size. This makes the tool well-suited for inspecting both mask and wafer size acceptability, as well as finding defects on both sides of the mask. In addition to its power of resolution, the asset also features two different optical features that allow for quick and accurate inspections. The model includes a live imaging feature, which simplifies and speeds up the process of inspecting the masks. The live imaging feature captures the images of the wafers in real-time and allows operators to quickly check for any defects within the image. This feature is especially useful in high-volume manufacturing applications, as it allows for quick replication of the same inspection results. The second feature of OSI POLYCHECK W-LAF is its automated defect sorting feature. The equipment is able to quickly and accurately sort defects based on their size and position on the mask or wafer. These defect sorting parameters can include x/y coordinates, area size, brightness/intensity, aspect ratio, and steepest/decay rate. This makes the entire inspection process much faster and more efficient, as operators can quickly identify areas that might need more detailed inspection. Overall, POLYCHECK W-LAF provides extremely high resolution scanning at impressive speed. Its live imaging and automated defect sorting features make it the ideal tool for quickly and accurately finding any defects in the mask or wafer. It is a powerful system that can save time and effort while ensuring that the finished product is defect-free.

There are no reviews yet