Used PARAGON Ultra 100 #9203541 for sale

URL successfully copied!

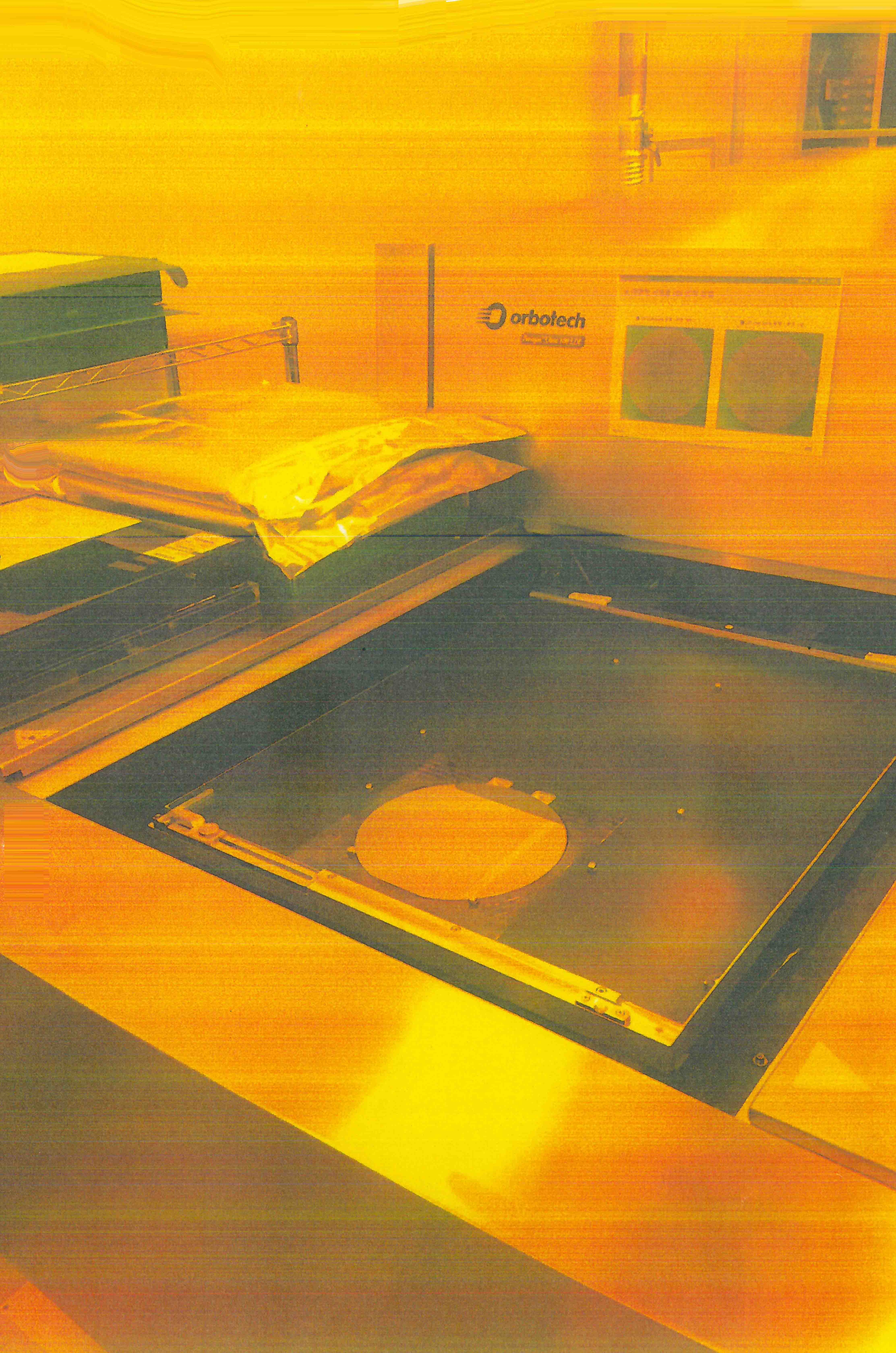

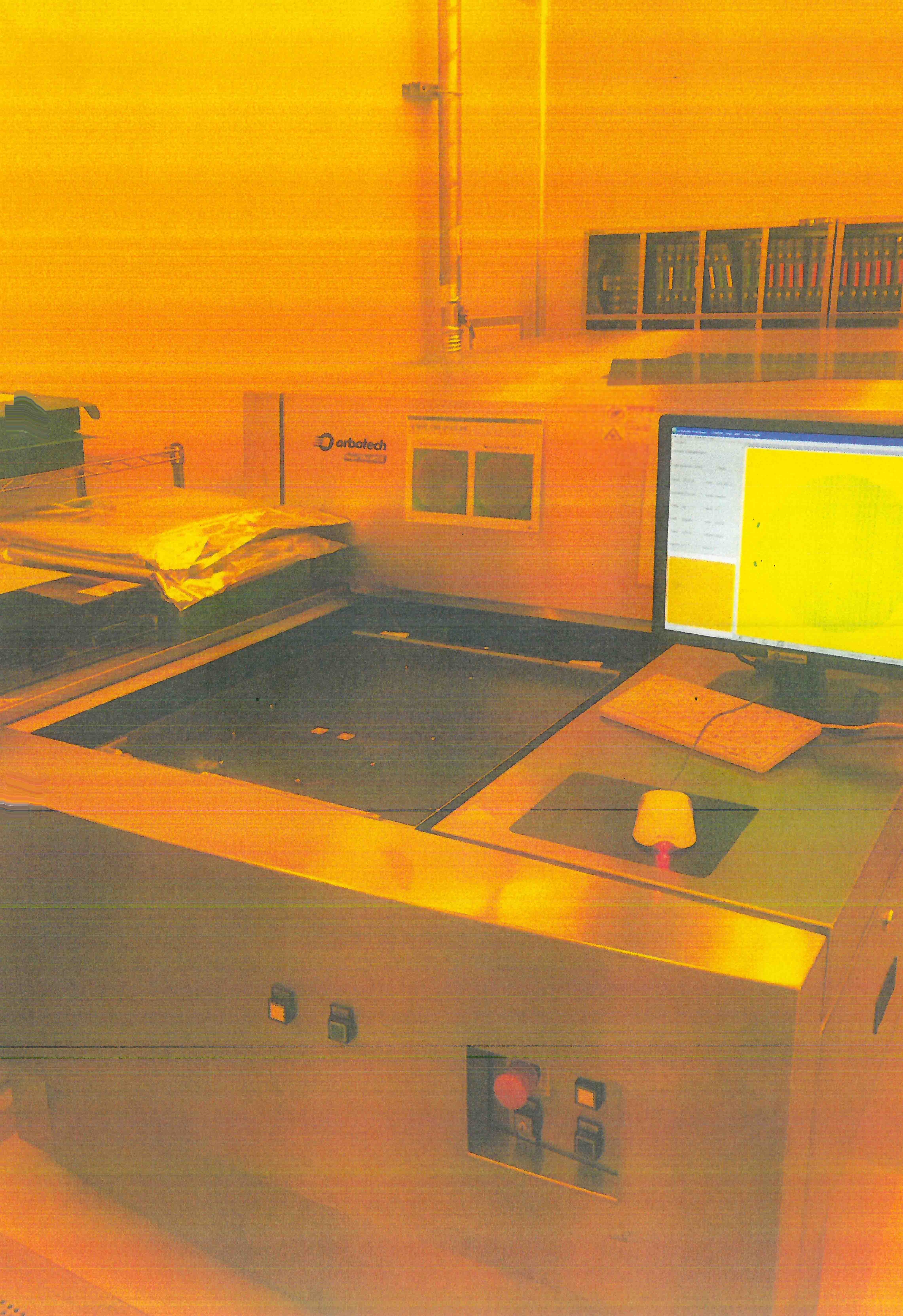

Tap to zoom

ID: 9203541

Laser imaging system

Minimum pitch: 30µm

Minimum feature size: 12µm

Data resolution: 1pm (25,400 dpi)

Edge roughness (3σ): ±1µm

Registration accuracy (FTG): ±5µm

Side to side registration (3σ): 10µm

Maximum substrate size: 558mm x 660mm 22" x 26"

Maximum image size: 508mm x 609mm 20" x 24"

Substrate thickness: 0.05mm to 3mm

Imaging wavelength: UV range, 355nm

Energy range: 10-2200 mJ/cm²

Different energy settings:

500 x 400mm, 4 Symmetrical targets, 6sec load/unload

10mJ/cm² - 34 panels/hour

80mJ/cm² - 34 panels/hour

100mJ/cm² - 30 panels/hour

120mJ/cm² - 25 panels/hour

Applications:

IC Substrates

Solder mask

Inner layers & outer layers

Sequential build-up layers

Flex & rigid-flex PCBs

Standard configuration:

Laser system

OPFX Input

RIP Server

8GB Raster memory

Scaling system & power vacuum

System options:

Hole-free inner layer registration

Partial scaling

Wise scaling

Stamping

2D Barcode stamp

Additional vacuum customization plate.

PARAGON Ultra 100 is a Mask & Wafer Inspection equipment that utilizes state of the art technology to provide in-depth analysis of critical layers, improving quality assurance and consistency for users. Using a CCD camera with a high speed scan, this system captures and evaluates a high resolution image of every die on the wafer and then compares it to a pre-defined standard. Ultra 100 unit is capable of detecting defects in a range of sizes, from small surface deformations to more obscuring defects. The machine's key feature is its ability to detect and measure parameters such as critical dimension (CD), spacing, overlay, linearity, isolate width, and line width. This is made possible by its powerful optics tool that is capable of magnifying up to 1000 X, enabling users to identify very small variations in critical layer designs. PARAGON Ultra 100 is also equipped with a variety of analysis software. This enables users to customize the asset to meet their specific needs and run a variety of tests quickly and efficiently. The software includes features such as pattern matching, signal simulation, noise reduction, and pixel intensity measurement. Furthermore, the software has automated routines for controlling the CCD camera and the software's graphical user interface makes it easy to use even for untrained users. Ultra 100 model is supported by a series of tools that make maintenance and servicing easy. Furthermore, its advanced calibration gives accurate and repeatable results, allowing users to easily measure the quality of their products. PARAGON Ultra 100 is designed for use in a number of industries, ensuring consistent high quality results. Ultra 100 is a powerful and advanced tool for mask and wafer inspection. Its combination of powerful optics and analysis software make it an invaluable tool for users who need high accuracy and reliability. It is an essential tool for ensuring consistent and high quality results and is a must have for any production line or quality assurance team.

There are no reviews yet