Used PARAGON Ultra 200 #9203540 for sale

URL successfully copied!

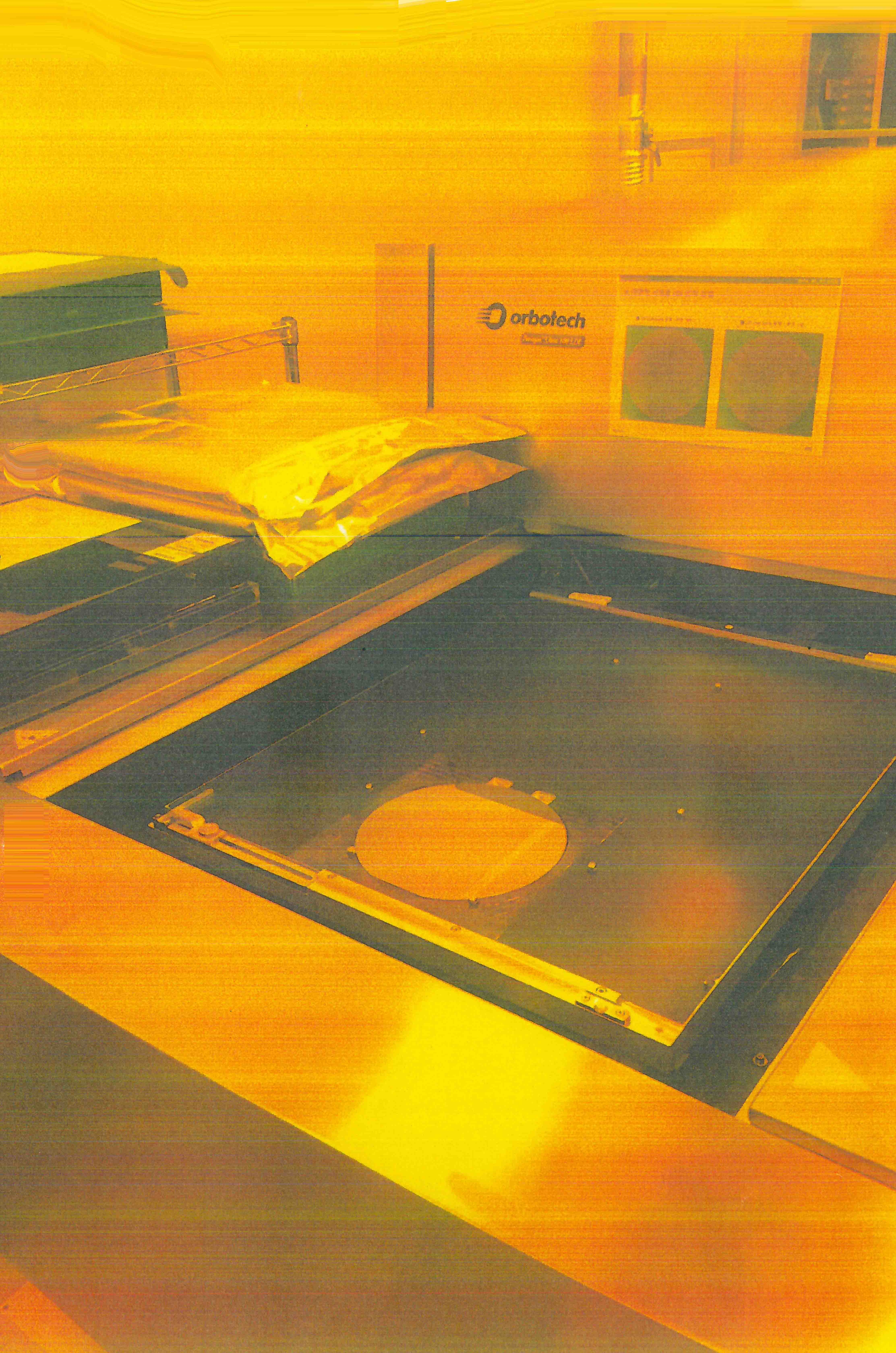

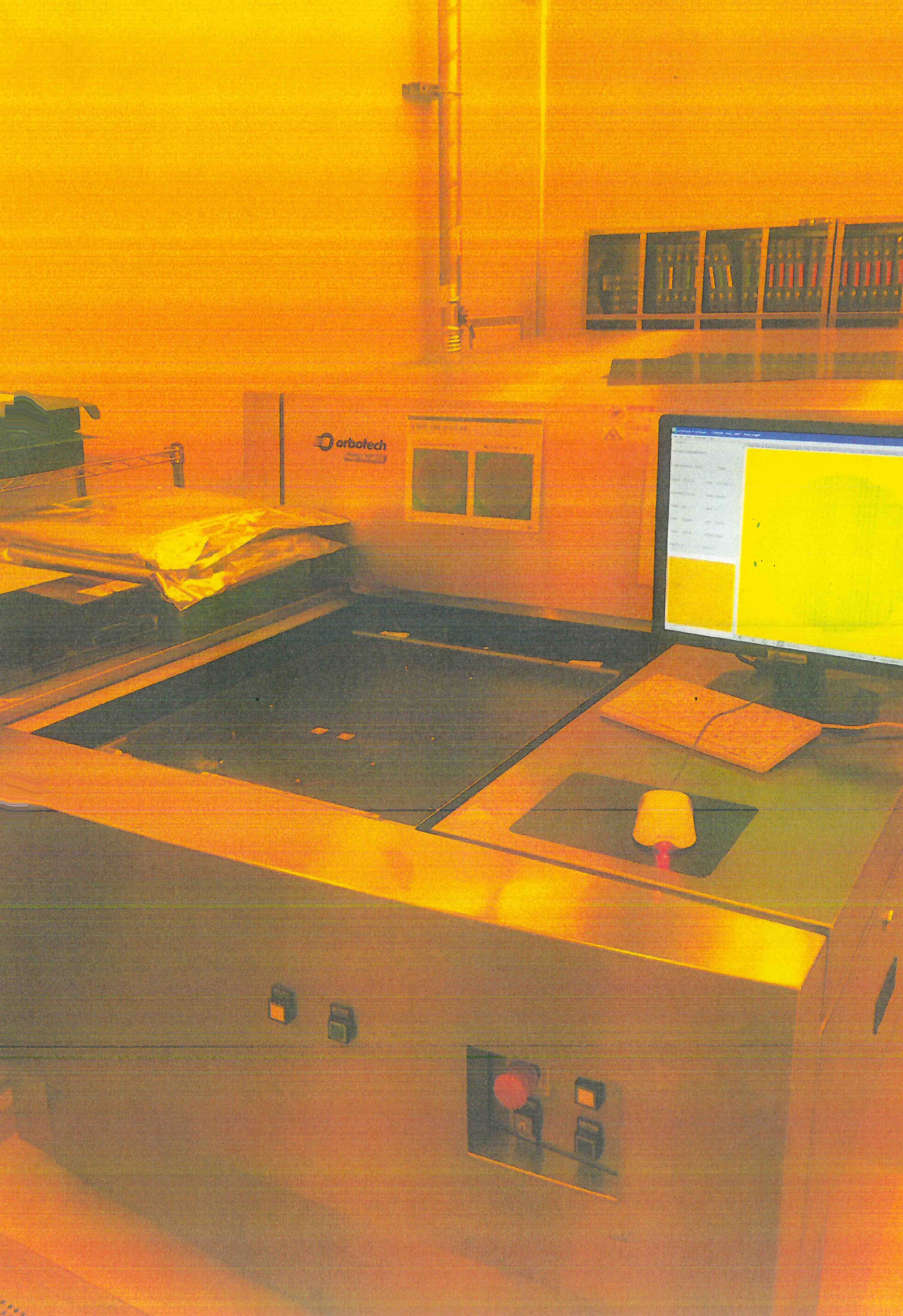

Tap to zoom

ID: 9203540

Laser imaging system

Minimum pitch: 20µm

Minimum feature size: 8µm

Data resolution: 1µm (25,400 dpi)

Edge roughness (3σ): ±1µm

Registration accuracy (FTG): ±5µm

Side to side registration (3σ): 10µm

Maximum substrate size: 558mm x 660mm 22" x 26"

Maximum image size: 508mm x 609mm 20" x 24"

Substrate thickness: 0.05mm to 3mm

Imaging wavelength: UV range, 355nm

Energy range: 10-2200 mJ/cm²

Different energy settings:

500 x 400mm, 4 Symmetrical targets, 6sec load/unload

10mJ/cm² - 34 panels/hour

80mJ/cm² - 34 panels/hour

100mJ/cm² - 30 panels/hour

120mJ/cm² - 25 panels/hour

Applications:

IC Substrates

Solder mask

Inner layers & outer layers

Sequential build-up layers

Flex & rigid-flex PCBs

Standard configuration:

Laser system

OPFX Input

RIP Server

8GB Raster memory

Scaling system & power vacuum

System options:

Hole-free inner layer registration

Partial scaling

Wise scaling

Stamping

2D Barcode stamp

Additional vacuum customization plate.

PARAGON Ultra 200 is a mask and wafer inspection equipment designed for accurately inspecting and measuring device features on semiconductor wafers. This system helps manufacturers meet high-level industry standards for yield and quality. The unit features a hybrid illumination machine, which has an adjustable back light to ensure accurate optical inspections across a wide range of semiconductor wafers. With this tool, manufacturers can perform more accurate inspections by adjusting the intensity of the light to match the refractive index of the wafer. Ultra 200 also features a 7 megapixel camera and advanced image processing algorithms, which ensure high-resolution detection and allow users to detect defects as small as 0.5 microns. The asset also has specialized software to analyze the scanned images and highlight potential defects. The model is capable of capturing images of two-dimensional (2D) and three-dimensional (3D) semiconductor devices, and supplies accurate process-specific information that can then be used for further analysis. In addition, the equipment can be used to analyze optical properties such as reflectivity, polarization, diffuse light, and birefringence. The system is also equipped with advanced calibration algorithms, which enable automated calibration of the imaging unit without user intervention. This ensures that the machine remains compliant with industry standards and gives the user accurate results. For manufacturing companies that wish to maintain the highest levels of quality, PARAGON Ultra 200 provides a reliable and accurate tool for mask and wafer inspection. The asset is highly reliable, with a high level of accuracy and precision. This allows users to detect defects with ease while also ensuring that their products meet industry standards.

There are no reviews yet