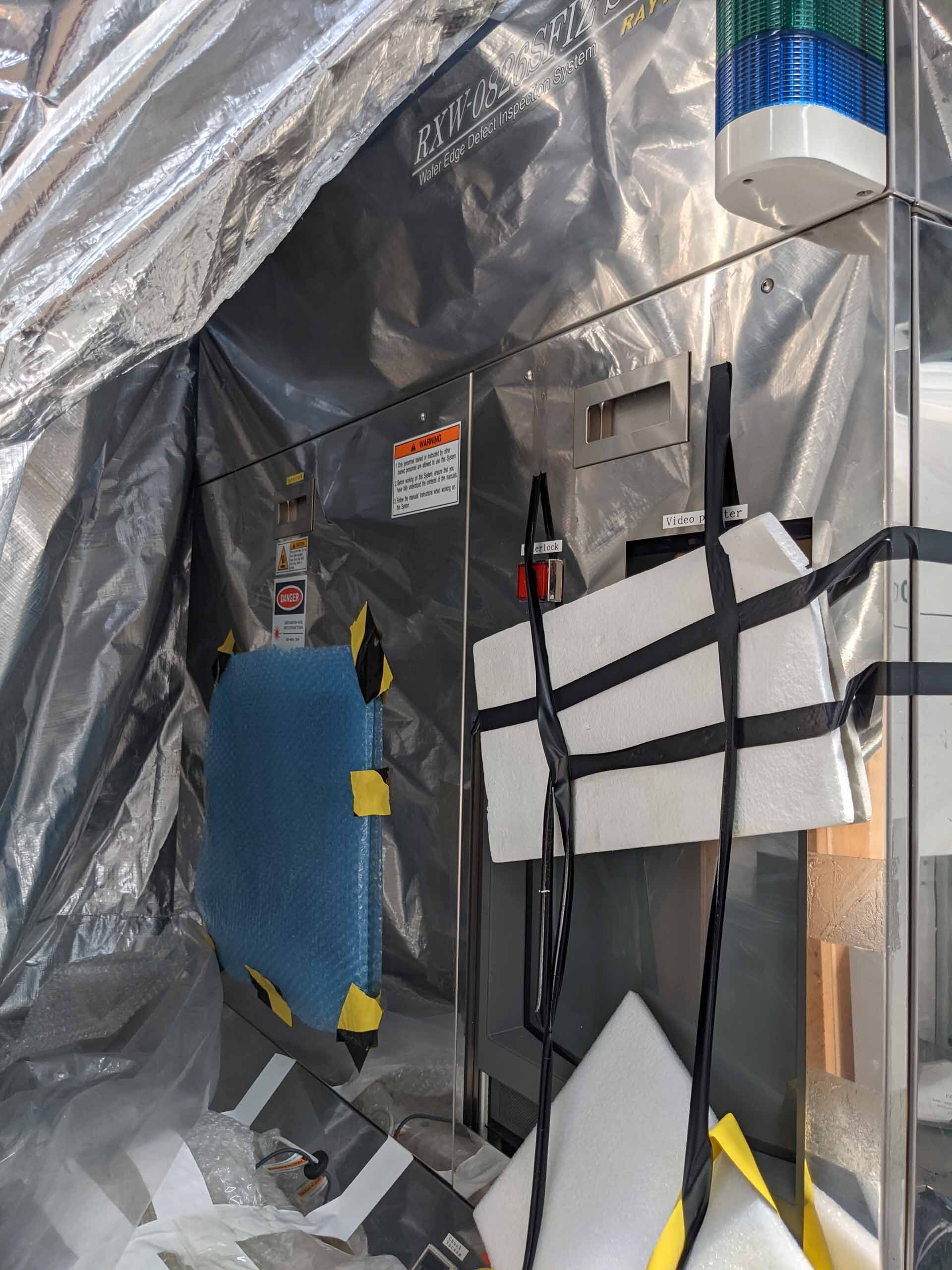

Used RAYTEX RXW-0826SFIX-SMIF #9384473 for sale

URL successfully copied!

Tap to zoom

RAYTEX RXW-0826SFIX-SMIF is a state-of-the-art automated mask and wafer inspection machine. This equipment provides high-resolution, 3D inspection of photomasks and semiconductor wafers with maximum accuracy and reliability. The built-in vision system delivers superior speed, accuracy, and comprehensive adjustability including automatic alignment. The unit is equipped with a precision high-magnification objective lens, high-resolution digital camera and light source. With its built-in micron-level resolution image processing, RXW-0826SFIX-SMIF provides precision patterning of otherwise difficult-to-detect features. This enables highly accurate wafer measurements such as overlay and dimension measurement, as well as sophisticated analysis such as contrast and pattern recognition. The user friendly touch screen makes operation simple and easy. RAYTEX RXW-0826SFIX-SMIF is also able to inspect weathered masks and chip substrates with high contrast inspections, scanning through a range of wavelengths and focusing light up to a resolution of 500 nm. This enables spotting of miniscule defects such as scratches, debris, and other types of contamination. It offers great adaptability to different process conditions and wafer types due to adjustable pressure and temperature settings. Moreover, the machine features an advanced wafer handling tool with automated exchangeable parts that ensure nonstop working. RXW-0826SFIX-SMIF's performance is further enhanced by its powerful image processing algorithms. They allow for dynamic resolution adjustments, pattern detection, and defect identification and classification. Moreover, the asset is compatible with all mask types including temporary and permanent. It is also equipped with an edge-bonded sample stage that ensures inspection accuracy and stability. In conclusion, RAYTEX RXW-0826SFIX-SMIF is an extremely advanced automated mask and wafer inspection model with impressive features including powerful image processing, automated exchangeable parts, pattern detection and classification, and compatibility with all mask types. Its precision optics and advanced imaging software make it one of the most reliable and accurate mask and wafer inspection systems available today.

There are no reviews yet