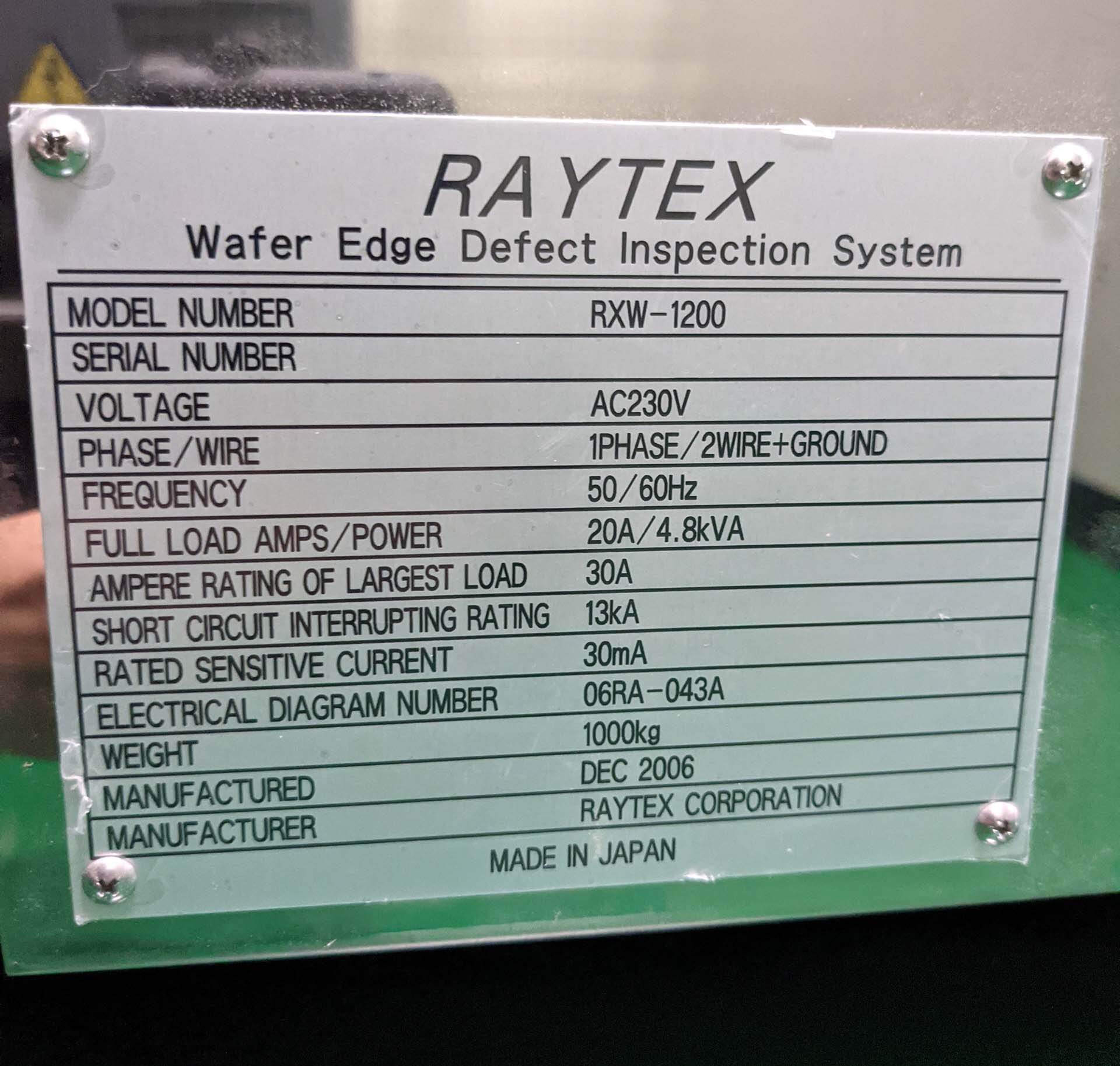

Used RAYTEX RXW-1200 #9204656 for sale

URL successfully copied!

Tap to zoom

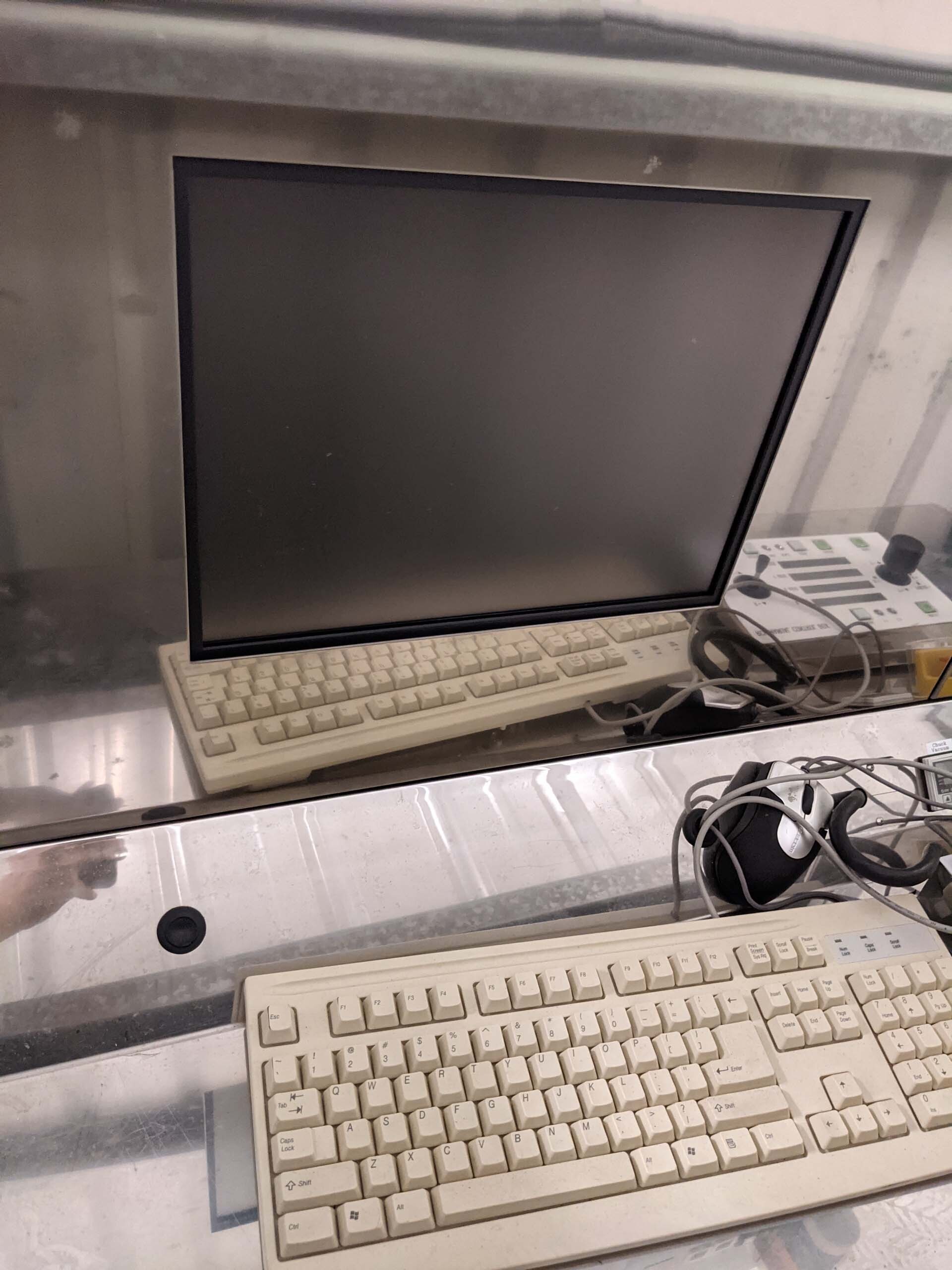

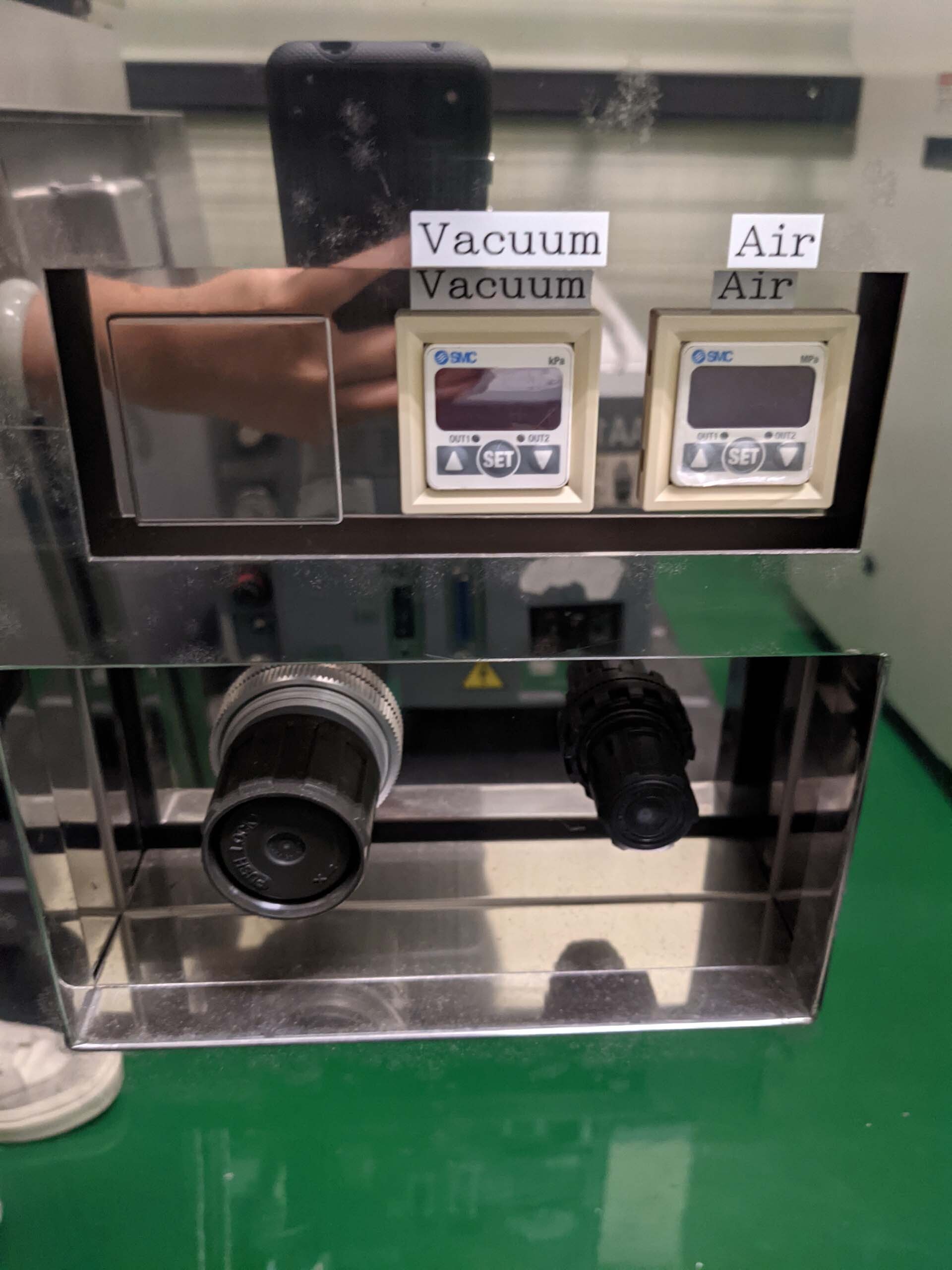

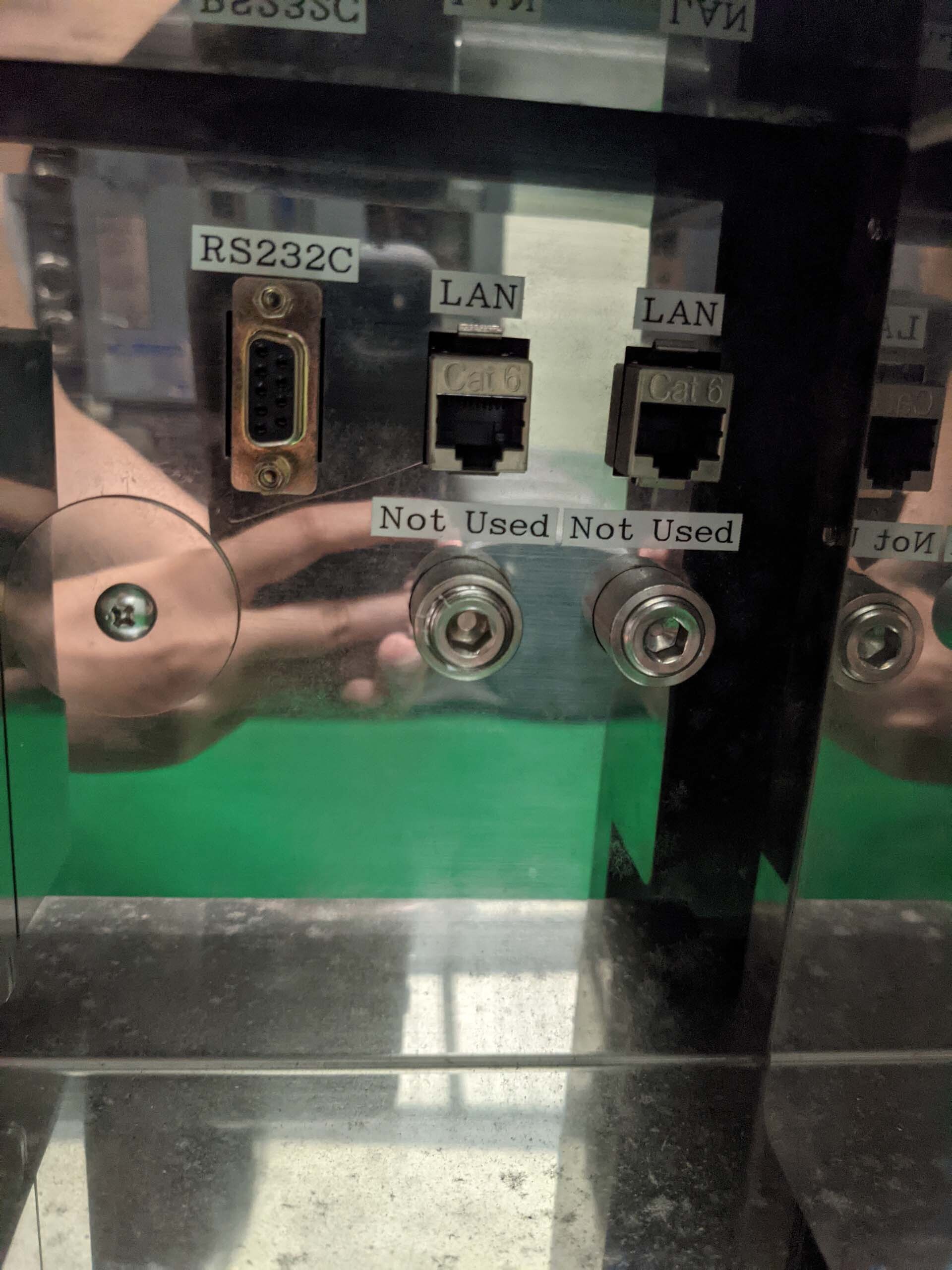

RAYTEX RXW-1200 is an advanced mask and wafer inspection equipment that helps wafer manufacturers to meet the optimum qualifications and compliance requirements of today's demanding semiconductor industry. This system utilizes a combination of hardware, software, and processing capabilities to deliver extremely precise digital inspections to ensure the highest quality standards. RXW-1200 has a unique design with multiple inspection modes that allow a single processor to support multiple defect types. This includes a high-powered optical inspection unit as well as a full-field optics machine. The tool also utilizes a large number of wafer sample holders for easy wafer exchange. The automated wafer handling asset enables a wide range of wafers to be scanned quickly. The model's software is highly advanced and supports a full range of wafer inspection settings. It provides multi-level defect checks, detect and reporting capabilities, and pattern recognition algorithms. It is also able to generate inspection reports tailored to the specific requirements of each individual customer. RAYTEX RXW-1200 has an integrated digital microscope with X and Y axes for high-definition imaging. It also has an integrated image analysis software that provides a fast and accurate visualization of the wafer's surface topography. It also supports a variety of image features, such as color adjustments, brightness and contrast, histogram and image information displays. In addition, RXW-1200 is accompanied with a range of accessories that include inspection fixtures, wafers and masks, a remote station controller, and a monitor for a comprehensive view of the wafer's surface. Furthermore, the equipment offers a powerful design automation environment with interactive tools that are able to support the most demanding project requirements. RAYTEX RXW-1200 is a comprehensive system designed to deliver efficient and high-quality wafer inspections. It is capable of meeting the highest industry standards while providing an extensive range of features and capabilities to its customers. It is an ideal choice for those seeking a reliable and robust platform for wafer inspection.

There are no reviews yet