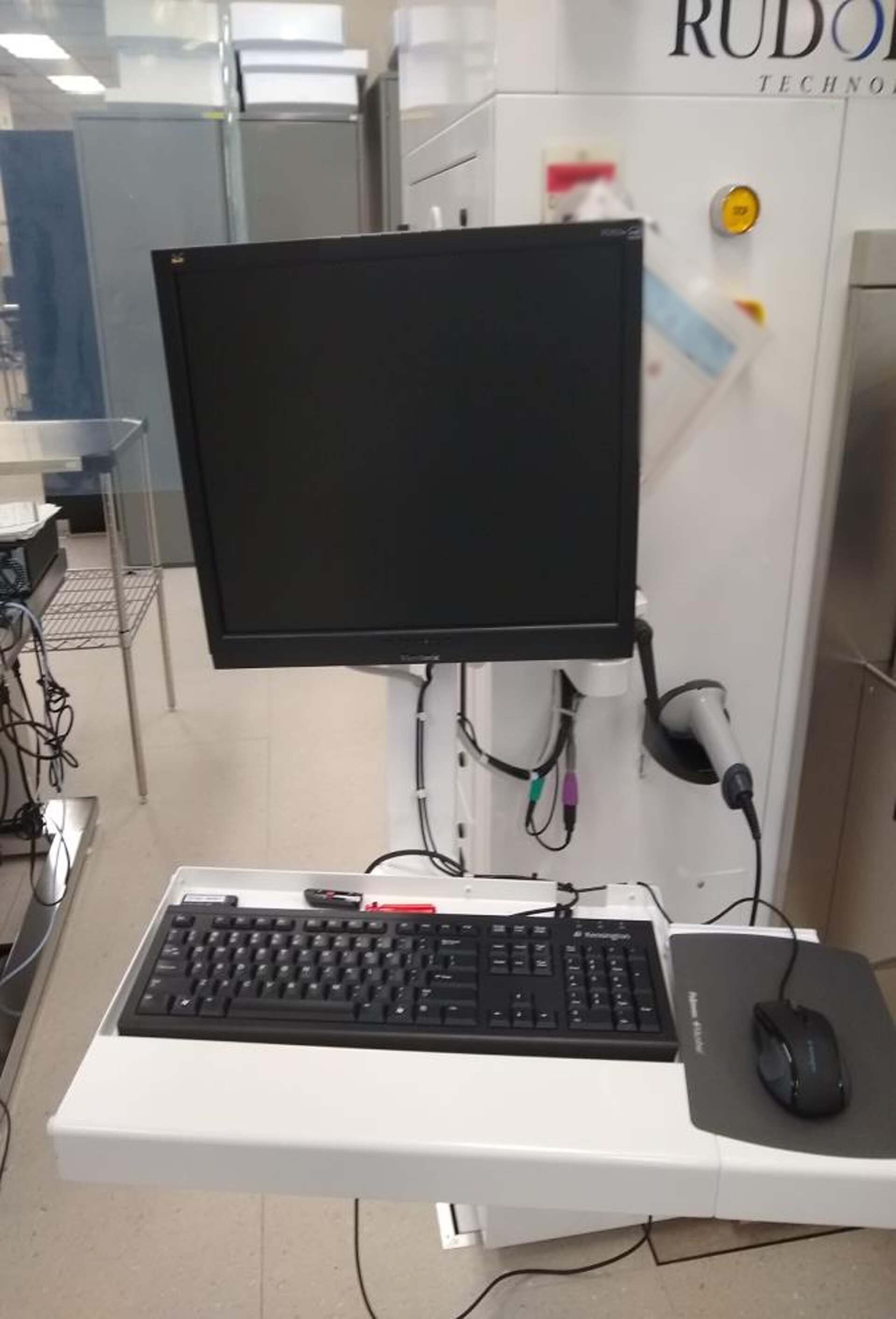

Used RUDOLPH / ONTO INNOVATION NSX 320 #9396970 for sale

URL successfully copied!

Tap to zoom

ID: 9396970

Wafer Size: 8"

Vintage: 2014

Automated defect inspection system, 8"

2W XPT Explorer function

Load port with robot handler

BASLER Inspection camera

Operating system: Windows 10

Power supply: 208-240 V, 50 Hz, Single phase

CE Marked

2014 vintage.

RUDOLPH / ONTO INNOVATION NSX 320 is an advanced mask and wafer inspection equipment designed to detect defects rapidly and accurately. The system features a highly sensitive camera, which captures images from the top and bottom of each wafer, allowing for multi-level inspection. The powerful imaging software can detect a wide range of defects that may pass undetected by other critical inspection systems, making it an essential tool for quality control in the semiconductor industry. RUDOLPH NSX 320 is a powerful yet easy to use unit. Its user-friendly interface and extensive range of customizable user options ensure that all mask and wafer inspections are performed accurately, quickly and reliably. The machine is suitable for 2D, 3D and 360-degree inspections, with the camera angle and focus adjustable to provide a comprehensive view of each wafer. The advanced software suite of the tool uses advanced algorithms to identify critical defects and can detect and classify particle defects, line defects and mylar defects, as well as other critical defects, with a high degree of accuracy. With its high speed, ONTO INNOVATION NSX 320 can detect and measure defects with a pixel size of less than 10 microns, providing complete coverage of mask and wafer inspections. NSX 320 features advanced inspection and mark recognition capabilities to accurately detect and measure defects that may be hidden from other inspection systems. It can also detect specific patterns, such as random dot defects and broken line defects, as well as other critical defects. The asset also features a powerful tool to measure and analyze defects for accurate traceability and reporting of results. Its unique technique is able to detect the defect locations on the wafer and generate a report of the defect's profile and other critical information. The model has extensive data storage and recall capabilities which enable fast and easy retrieval of results. RUDOLPH / ONTO INNOVATION NSX 320 can also receive data via web services or through use of a USB drive, allowing for remote collaboration and data exchange between multiple equipment users. End users of RUDOLPH NSX 320 are able to rely on the system's high-speed, high-accuracy performance to ensure the quality of their products. Through its easy to use interface, powerful imaging and analysis tools, and extensive storage and recall capabilities, ONTO INNOVATION NSX 320 is an essential solution for advanced mask and wafer inspections.

There are no reviews yet