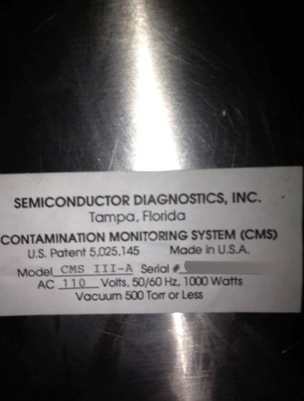

Used SDI CMS III-A #9045538 for sale

URL successfully copied!

Tap to zoom

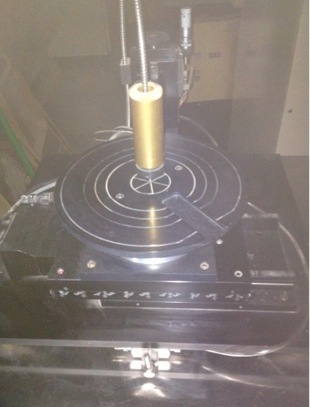

SDI CMS III-A is a mask and wafer inspection equipment designed for high-speed, high-throughput analysis of wafer and semiconductor mask patterns. This system utilizes a state-of-the-art automated scanning unit, with 250nm resolution to measure and evaluate the structures on the wafer and masks for defect analysis. Its inspection capabilities provide users with a fast, accurate, and reproducible inspection that can detect and analyze various types of defects, including lithographic errors, thinned masks, missing via features, and contamination. The machine consists of four main components: the light source, the illuminated wafer, the image sensor, and the computer, connected to a monitor. The light source is a combination of two ultraviolet lasers which provide monochromic illumination for accurate imaging; a liquid crystal display (LCD) which optimally directs the laser light and minimizes exposure of the device to radiative heat; and a diffractive optical element (DOE) which increases the field of view of the tool and reduces the number of images needed for analysis. The illuminated wafer is placed above the LCD and exposes the target structures to the laser light, which is then detected by a CMOS image sensor. The image sensor is capable of resolving structures as small as 250nm, and samples the images and sends them to a computer for analysis. The sophisticated processing algorithms present in the asset allow for capturing and analyzing the images within seconds. It is designed to detect any kinds of defects, including missing features, irregularities in the structure, scratches, contamination, and more; and to generate comprehensive reports so that engineers can troubleshoot any issues quickly. The computer is also connected to a monitor which displays the captured images as well as all the data gathered by the model. This mask and wafer inspection equipment is recommended for any fabrication plant and laboratory setting in the semiconductor industry, offering users the ability to inspect wafers and masks quickly and accurately at high speeds, while utilizing highly advanced analysis algorithms for the detection of defects. This system is designed for ease of use and allows for fast, accurate inspection and analysis of the wafer and mask structures.

There are no reviews yet