Used SEMILAB / SDI FAaSt 300-SPV #173920 for sale

URL successfully copied!

Tap to zoom

ID: 173920

Wafer Size: 8"-12"

Vintage: 1997

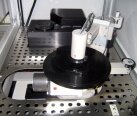

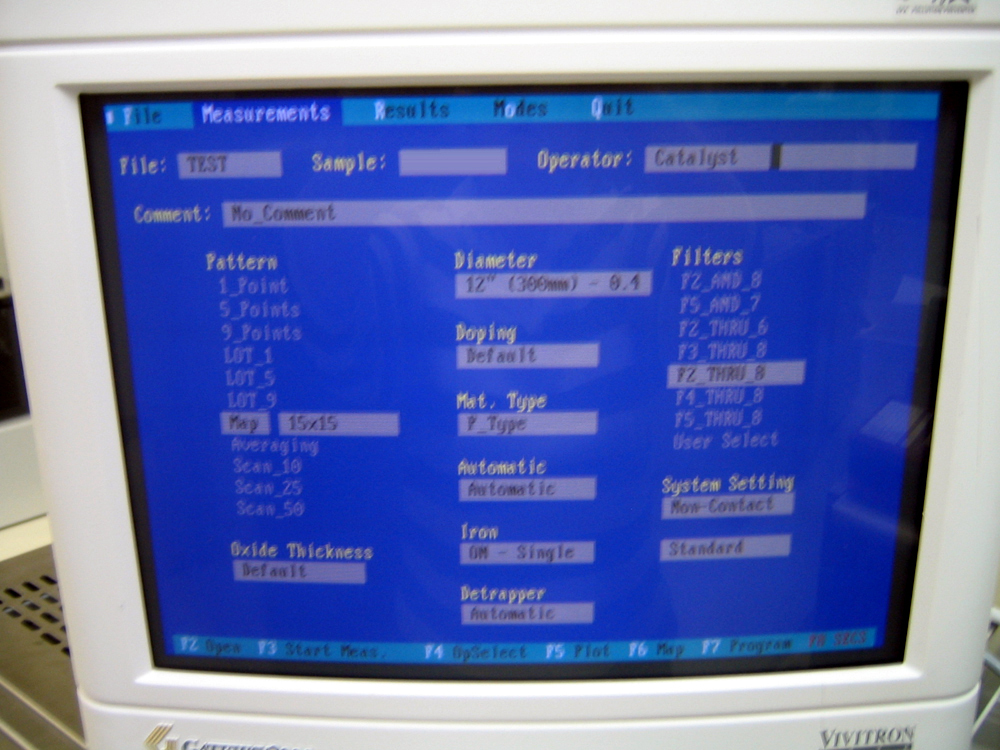

Surface photo voltage tester, 8"-12"

Contact and non-contact surface photo voltage test capability

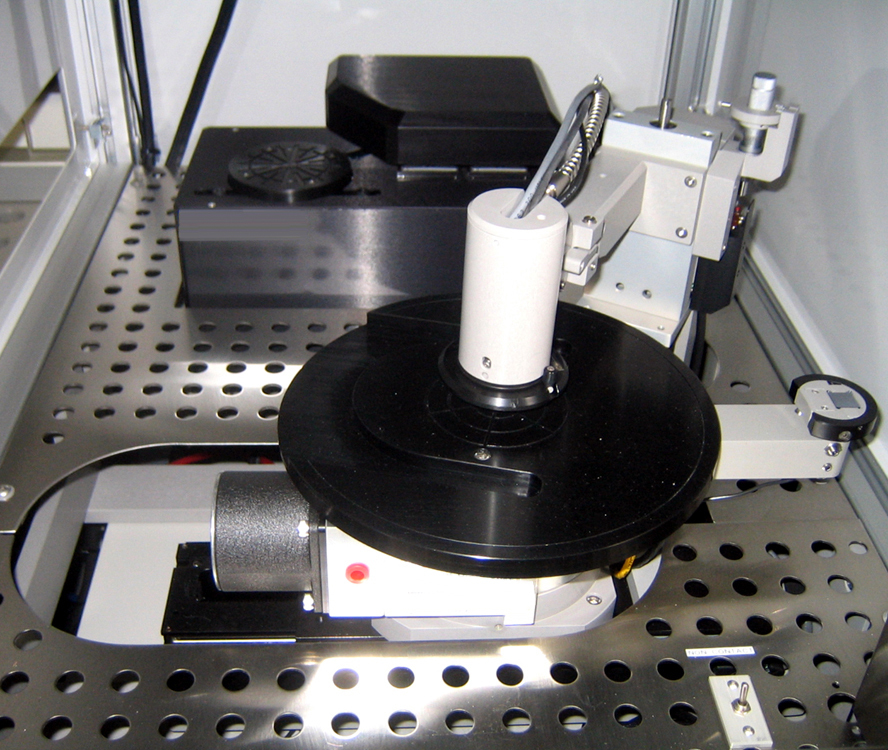

Open cassette handling

EQUIPE TECHNOLOGIES ATM-105 Wafer handling robot

EQUIPE TECHNOLOGIES ESC-212 Robot controller

EQUIPE TECHNOLOGIES PRE -3019 Wafer pre-aligner

(2) NEWPORT RESEARCH MM3000 Motion controllers

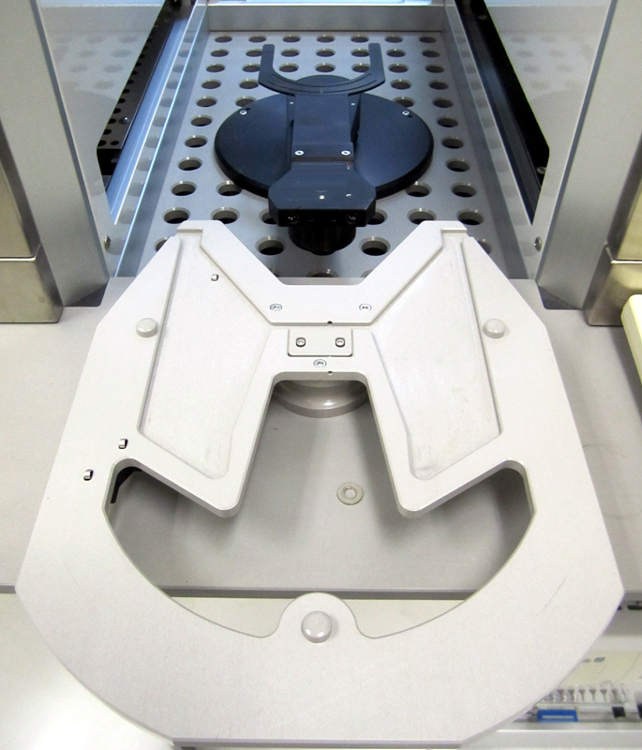

Light activation module:

Designed for 200mm & 300mm wafers

SDI Control Fe activation controller

Dual halogen lamp housings

Wafer analysis module:

EG&G PAR 7260 DSP Lock-In amplifier

SDI LPS-12 Power supply

SDI Opto coupler

Reference light module:

Halogen lamp housing

EG&G PAR 197 Light chopper

Filter wheel assembly

(8) Filters

Fiber optic light delivery

Wafer analysis chuck:

Anodized aluminum wafer chuck, 8"

Designed for 200mm & 300mm wafers

Calibration chip fixture

HEWLETT PACKARD Vectra XA computer:

3.5” Floppy disc drive / CD-ROM Drive

SYQUEST ezflyer 230GB Backup tape drive

Color LCD monitor, 15”

Ghost HDD included

1997 vintage.

SEMILAB / SDI FAaSt 300-SPV is an industry leading mask and wafer inspection equipment. This system is capable of delivering high resolution imaging, fast throughput, and comprehensive image logic. As an advanced unit, it combines the advanced features of a standard mask and wafer inspection machine with the flexibility of a fully configurable platform. The primary tool consists of two main components: a mask inspection chamber and a wafer inspection cell. The mask inspection chamber is capable of supporting a wide range of masks and provides full-field, high resolution images of up to 146 million records per second. It features an ultra-low-noise digital signal processor (DSP) allowing for simultaneous imaging, scoring and analysis of up to twenty-four masks in one batch. The wafer inspection cell offers a comprehensive set of inspection functions, including high resolution imaging of up to 24 million pixels per second and advanced image logic for automated defect classification. SDI FAaSt 300-SPV also offers a variety of processor and data management solutions. It supports flexible logic functions and data acquisition enabling users to tailor the asset to their specific inspection needs. It also allows for the integration of additional inspection systems or components. With its fully configurable platform and fast image throughput, the model can be configured to efficiently address the most challenging failure analysis applications. In addition to its imaging and data acquisition capabilities, SEMILAB FAaSt 300-SPV is also equipped with advanced tools for automated defect characterization and analysis. These include defect isolation, microscope analysis, automated test analysis, fault simulation, and optoelectronic layout view. This allows users to quickly identify and rectify defects in order to avoid costly downtime due to costly failures. FAaSt 300-SPV is an industry leading solution for mask and wafer inspection. With its combination of advanced imaging, fast image throughput, and comprehensive image logic, the equipment offers unmatched flexibility and performance for demanding failure analysis applications. Its configurable platform and powerful data management solutions ensure that users can address their most challenging failure analysis needs with confidence.

There are no reviews yet