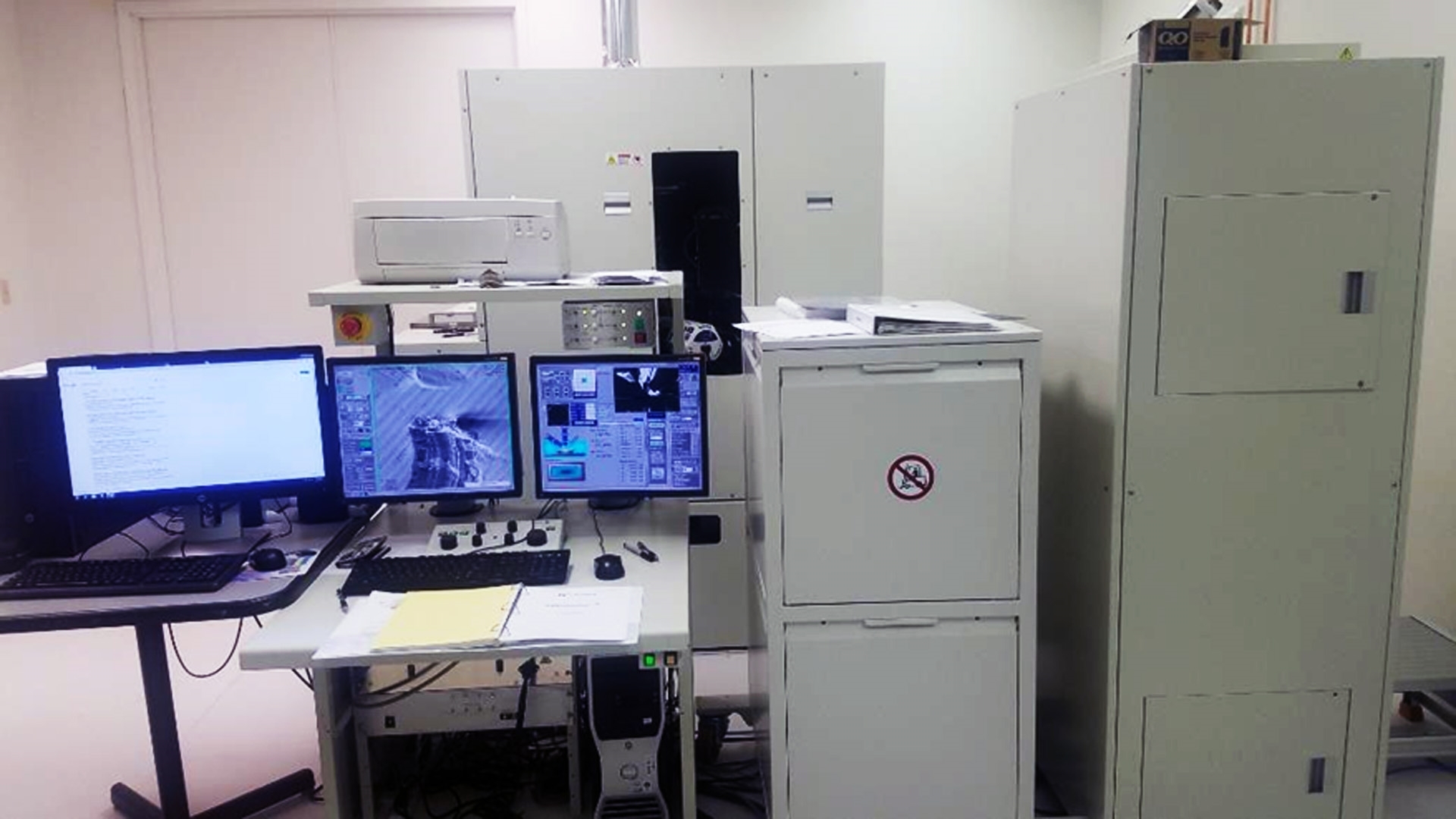

Used SII NANOTECHNOLOGY / SEIKO XVision 200TB #9240326 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9240326

Defect inspection system

Triple beam

FIB:

Resolution: 4 nm at 30 kV

Acceleration voltage: 0.5 ~ 30 kV

Maximum probe current: 90 nA

Maximum probe current density: 45A/cm²

Argon:

Resolution: 3 nm at 5 kV

Acceleration voltage: 1 ~ 30 kV

SEM:

Acceleration voltage: 0.5 ~ 1 kV

Maximum beam current: 10 nA

EDS Specification:

AZTec Energy Standard micro-analysis system

With X-MaxN 80 large area analytical silicon drift detector

Hardware includes:

X-MaxN 80 SDD Detector with PentaFET precision

Active area: 80 mm²

Resolution guaranteed on Mn K - 127eV at 50,000 cps

SATW Windows for detection of elements from beryllium

MicsF+ Microscope image capture system

X-Stream 2 Micro-analytical pulse processor

PC

Operating system: Windows 7

Widescreen LCD display, 23"

Aperture: 1

Accelerating voltage: 3 kV

Beam current: ~210 pA

(3) Separate beams:

High resolution FE-SEM imaging

Precision FIB milling

Ultra high resolution TEM imaging:

Low energy Ar polishing to minimize sample damage

FIB-SEM-Ar beams:

Coincident eliminating need for sample movement between beams

FE-SEM Monitoring.

SEIKO X Vision 200TB mask and wafer inspection equipment is a state-of-the-art technology with high resolution, high throughput, and high accuracy. This system is ideal for advanced microelectronic, medical, and flat panel display applications. SII NANOTECHNOLOGY X Vision 200TB unit has a 4,000 pixel resolution CCD camera and built-in high-power illumination machine. This allows for high-define image capture in all working directions with high-quality imaging of any defects and other characteristics. The tool also has SII NANOTECHNOLOGY / SEIKO exclusive auto focus technology that provides accurate, high-definition images quickly and efficiently. This allows users to reduce costs and improve the quality of their masks and wafers by performing onsite inspections and rejections. The inspection asset also features an ergonomic design and intuitive user interface. This allows for efficient and convenient workflows. The model has a powerful image processing equipment that automatically detects and corrects for defects in the masks and wafers. Additionally, it features an advanced defect library that contains a wide range of defect types for easy detection and grouping. SEIKO X Vision 200TB mask and wafer inspection system is designed for maximum efficiency with its easy-to-use software and user-friendly commands. This unit offers high performance and an array of powerful tools for data analysis, reporting, and archiving. Its advanced defect classification capabilities make it ideal for data mining and categorizing defects. The machine is equipped with a selection of customizable image enhancement tools to improve pattern visibility. It also features hard copy reports and digital archiving capabilities to record findings. Additionally, SII NANOTECHNOLOGY X Vision 200TB's customizable data analysis features allow the user to analyze and archive data quickly and accurately. Overall, SII NANOTECHNOLOGY / SEIKO X Vision 200TB mask and wafer inspection tool offers unsurpassed quality and accuracy for reliable quality assurance and inspection of circuit patterns. This asset provides a cost-effective solution to meet the tight tolerances of advanced semiconductor and medical device manufacturing processes. With its high resolution, throughput, and accuracy, the model is perfect for any complex mask and wafer inspection applications.

There are no reviews yet