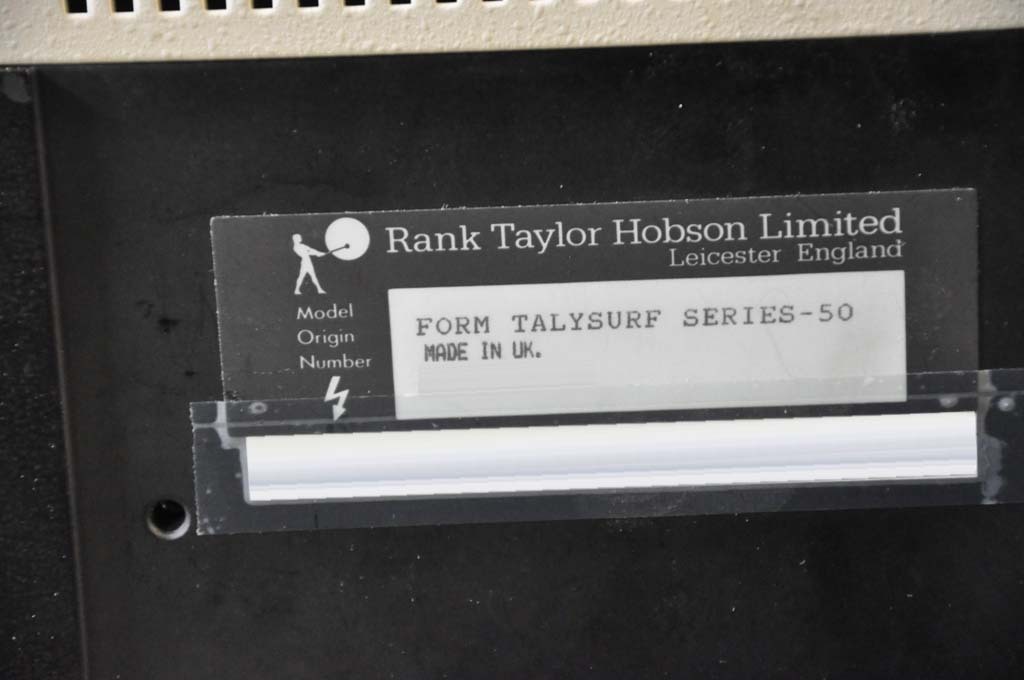

Used TAYLOR HOBSON TalySurf 50 #9090641 for sale

URL successfully copied!

Tap to zoom

ID: 9090641

Measurement system

Granite surface plate: 48" x 120" x 16" Thick, finished on top surface only

(2) Steel bars bolted to the granite plate

Measuring:

5" Wide x 120" long x 1 ½" thick

4 ¼" Wide x 72" long x 1 ½" thick each with a full length T slot

High steel stand for granite plate: 20"

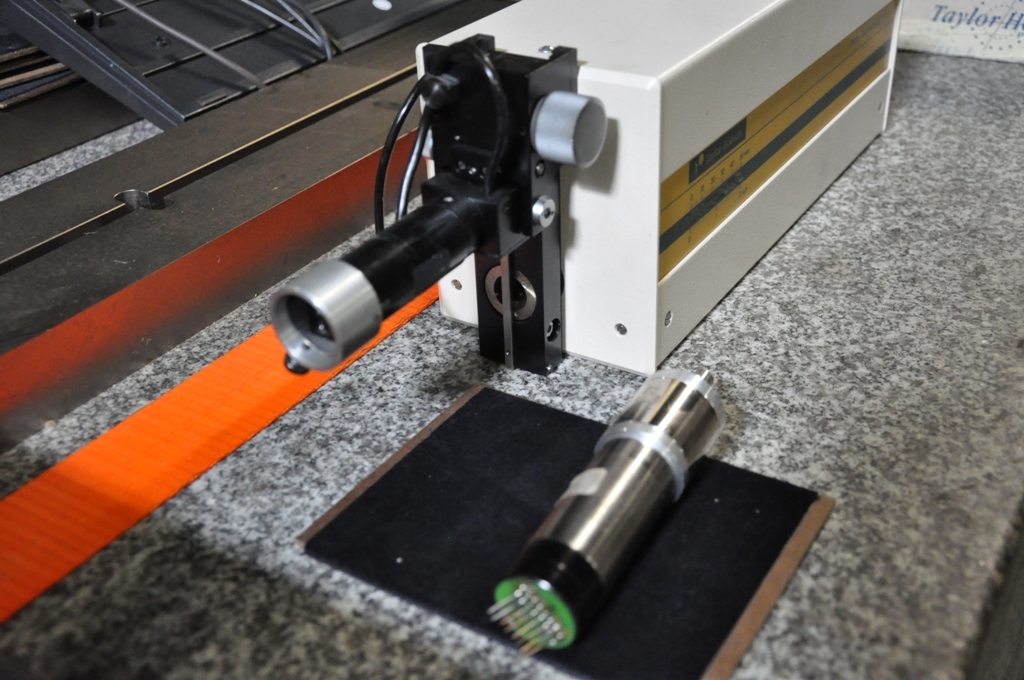

Rank TAYLOR HOBSON granite vertical column #112/2005-797

Travel of head on vertical column: 18"

Column rotates 360 degrees

Rank TAYLOR HOBSON form Talysurf 50 head: #112/2002/428

(3) Assorted probes

Barry serva-level vibration system with small air compressor and controller

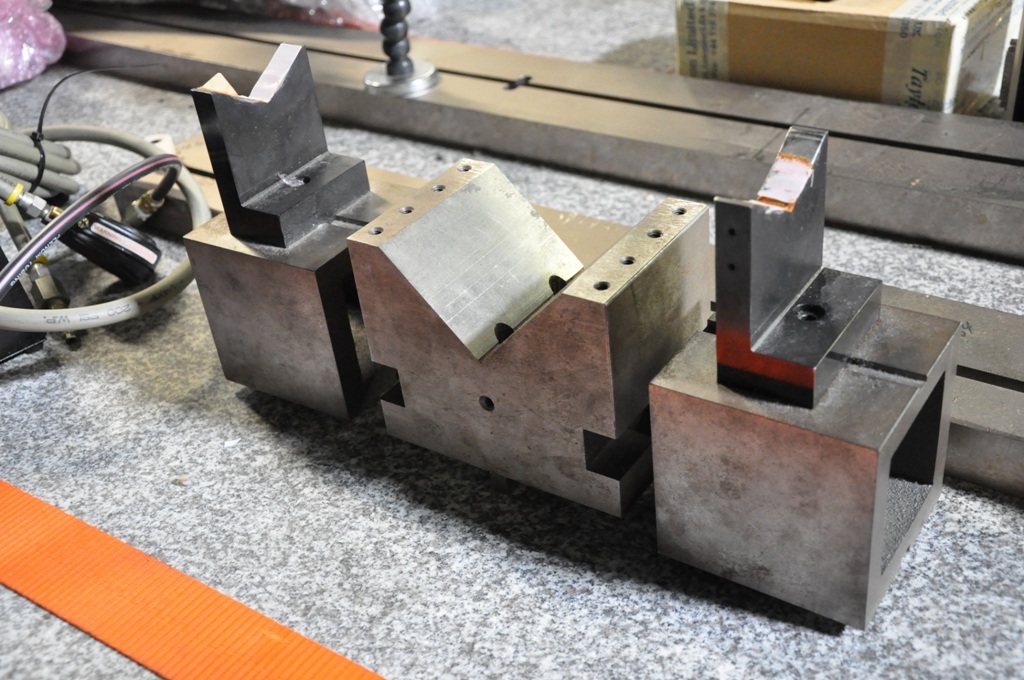

(3) Assorted V stage blocks

TAYLOR HOBSON precision form Talysurf series 2 control unit

Dell Optiplex GX260 computer

Dell Precision 360 computer

(1) Dell computer monitor: 15"

Computer keyboard, mouse and cables

Sekonic S-200GP printer plotter, 81/2 x 11 tractor feed, Dot matrix

Lexmark Z55 inkjet printer

Windows 2000 Professional, Windows 3.1 and Windows XP software

DataMyte software:

Rank TAYLOR HOBSON software revision 5.02 / 112/2086 on (3) 3 ½" Discs

Rank TAYLOR HOBSON software version ultra 4.3.14 on (1) CD

Rank TAYLOR HOBSON license file on (1) 3 ½" disc

(2) Computer speakers

Assorted cable

Metal cabinet on wheels

Currently warehoused.

TAYLOR HOBSON TalySurf 50 is a comprehensive mask and wafer inspection equipment that operates with advanced technology to provide accurate real-time wafer and mask inspection. The system is ideal for use in semiconductor, electronics, and optics industries to monitor production processes and ensure that parts meet the specified requirements. The unit features a high resolution sensor head, which is capable of detecting very small surface faults in the wafer or mask. The sensor head is linked to state-of-the-art software which allows for real-time analysis of the surface features. This software is easy to use and provides a range of functions which can be used to analyse data such as mapping, flatness, contamination, and surface roughness. TalySurf 50 is equipped with a 3D surface profilometer which allows for accurate three-dimensional imaging of the wafer or mask surface. This profilometer utilizes a white light interferometer which projects a spotlight onto the wafer or mask surface and then creates an image of the surface features. This image can be used to quickly identify surface distortions or anomalies, which can then be remedied. The machine also features a high-precision rotary table for easy sample positioning and handling. This rotary table allows for fast and accurate sample placement and provides a large amount of freedom for adjustments while maintaining a stable positioning. TAYLOR HOBSON TalySurf 50 also features a high-resolution display and control panel for easy viewing and editing of data. The control panel allows the user to view and adjust data quickly while the high resolution display offers clear visuals of the data being analysed. In addition to the hardware featured on the tool, TalySurf 50 also utilizes a variety of software features such as interactive analysis tools, a high-speed video capture and replay asset, calibration functions, and report generation capabilities. TAYLOR HOBSON TalySurf 50 is a powerful and accurate model that provides a fast and reliable inspection process for mask and wafer manufacturers. The equipment is designed with advanced features to provide accurate, real-time data that can be quickly analysed and remedied.

There are no reviews yet