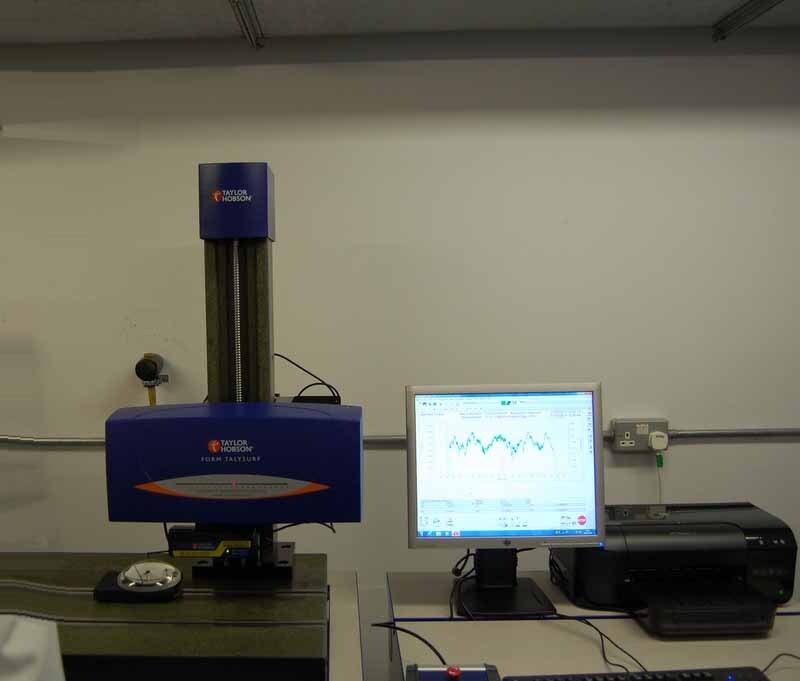

Used TAYLOR HOBSON TalySurf #9153363 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9153363

Wafer Size: 8"

Vintage: 2014

Automated surface and contour inspection system, 8"

System hardware

Anti-vibration support frame

TalySurf granite base and column

TalySurf traverse unit

PGI gauge

System control & analysis

Electronic control unit (ECU)

ECU (S21) control software

Ultra control & analysis software

Licensed dual profile analysis software (Ultra)

Licensee roughness (VDA 2005) analysis software (Ultra)

Licensed waviness analysis software (Ultra)

Licensed parameter tolerancing software (Ultra)

Licensed aspherics analysis software (Ultra)

Licensed conic section analysis software (Ultra)

Licensed form measurement software (Ultra)

Required options

Gauge range

Range = 12.5mm (PGI1200)

Gauge resolution

Gauge resolution 0.2nm

Stylus lilt options

Standard gauge control with motorized lift lower

Traverse length

200mm traverse

Column height and tilt

450mm column with non-tilting traverse

Instrument platform

Pneumatic AV platform including desk for pc

Computer & monitor

High grade pc (processor, memory, hard drive, cd / dvd)

Intel Pentium processor (2.0 GHz. 1mb l2 cache, 800 MHz FSB)

2GB ram

160 GB hard drive (SATA 3 Gb/s), 16x dvd r/w

Monitor

19" LCD (hi res)

Styli

60mm arm with 2um radius & 60dog cone

120mm arm with 0.3mm diameter (ruby)

60mm arm with 2um radius & 90deg cone

60mm arm with 5um radius and 90deg cone (recess)

60mm stylus arm with 2um rad *10deg conisphere diamond tip

60mm stylus arm with 0.8mm diameter ball silicon nitride tip

120mm arm with 0.8mm diameter (silicon nitride)

Calibration standards

Calibration standard (80mm radius)

Staging

Air bearing rotary stage

Mains power

220vac (+/-10%)

Mains lead

Mains lead (UK)

Datum correction

Datum correction pack

Part number Description

M112-4117-02 Form talysurf PGI optics Std

112-3145-06 S21 PGI 12mm Gauge

112-3984-01 02nM PGI Software licence

112-3821-01 PGI Iift /lower

112-3123-02 S21 200rnm Traverse unit

112-3849-01 S21 450mm Fixed col granite

112-4177-01 PGI Pneu AV Base+Desk+Surround

112-4241-01 L2 Enhanced aspherics anaylsis

112-4344 02 HP DPU - All Languages

112-4120-01 Hewlett packard 19" disply

112-3227-02 60mm 60J 2uM Recess PGI stylus

112-3221-02 60mm 90J 2uM Recess PGI stylus

112-3224-01 60mm 5uM Radius 90 deg

112-3412-02 60mm 40 2uM Recess PGI stylus

112-3411-01 60mm 0.8mrn Diameter ball

112-3404-01 120mm 0.3mm Diameter ball

112-2028-01UC Cal Std 80mm Rad & UKAS Cert 220V 220VAC (+/-10%)

LANG-ENG English

112-2367 FEC 119-6440 Mains lead (UK)

112-4147-01 Datum correction pack

SPECIALDP RT150/200-A2 Precitech rotary

SS TRAIN THLE Training at TH Leics

SS INST THUK Install by TH UK engineer

112-3405-01 120mm 0.8mm Diameter ball

2014 vintage.

The Taylor-Hobson TAYLOR HOBSON TalySurf is an advanced optical metrology equipment based on 3D optical profilometry. This system is ideal for non-destructive testing of mask and wafer-level features in order to ensure surface quality and flatness in the semiconductor manufacturing industry. The unit is based on a patented Talyprofiler 3D scanner with an industry-standard RMDx optical profilometry module, capable of providing accurate results in as little as 1 second. TalySurf has been specifically designed to meet the needs of manufacturers who produce semiconductor wafers and masks in order to meet the stringent industry standards of quality. It can detect even the smallest features and defects on wafers and masks in up to 25 micron datum per pass, making it an incredibly precise and reliable machine. TAYLOR HOBSON TalySurf offers a full range of features, such as user-friendly software with point-and-click measurement tools, as well as advanced software for surface profilometry, coating thickness measurements, and advanced image analysis. The tool is designed to capture high resolution images of the surface in both the horizontal and vertical planes, which can be converted into graphs for easy comparison against industry standards. It can also be used to measure feature lengths, depths, and diameters, as well as high precision surface profilometry at the nanoscale. TalySurf features a built-in, integrated vision sensor that uses a combination of advanced algorithms and pre-defined measurement templates to accurately determine the 3D properties of the target surface. TAYLOR HOBSON TalySurf is incredibly easy to set up and use for mask and wafer inspection, and requires only basic operator training to make the most of it. It has a wide variety of customizable options available, including a wide selection of lighting angles, focus settings, and scanning speed for specific materials. The asset also features software that allows data to be transferred quickly and securely as well as remotely controlling the device. Overall, the Taylor-Hobson TalySurf is an incredibly reliable and cost-effective device for mask and wafer inspection applications. Its precise measurements and advanced software makes it an ideal choice for any company in need of accurate and reliable inspection results. Its user-friendly design and intuitive setup make it easy to use, even for inexperienced operators, and it has a wide selection of customizable settings to suit various materials and process requirements.

There are no reviews yet