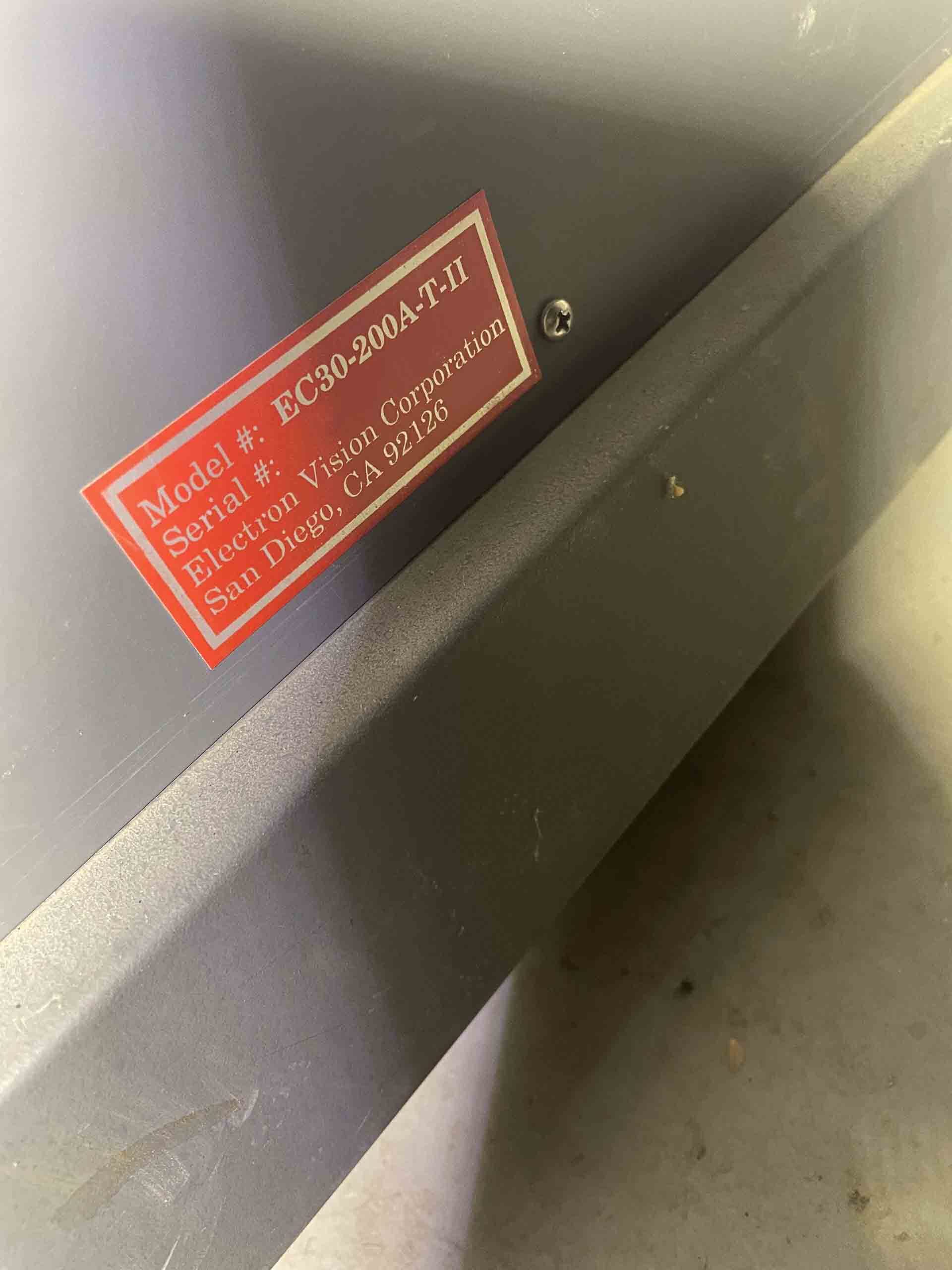

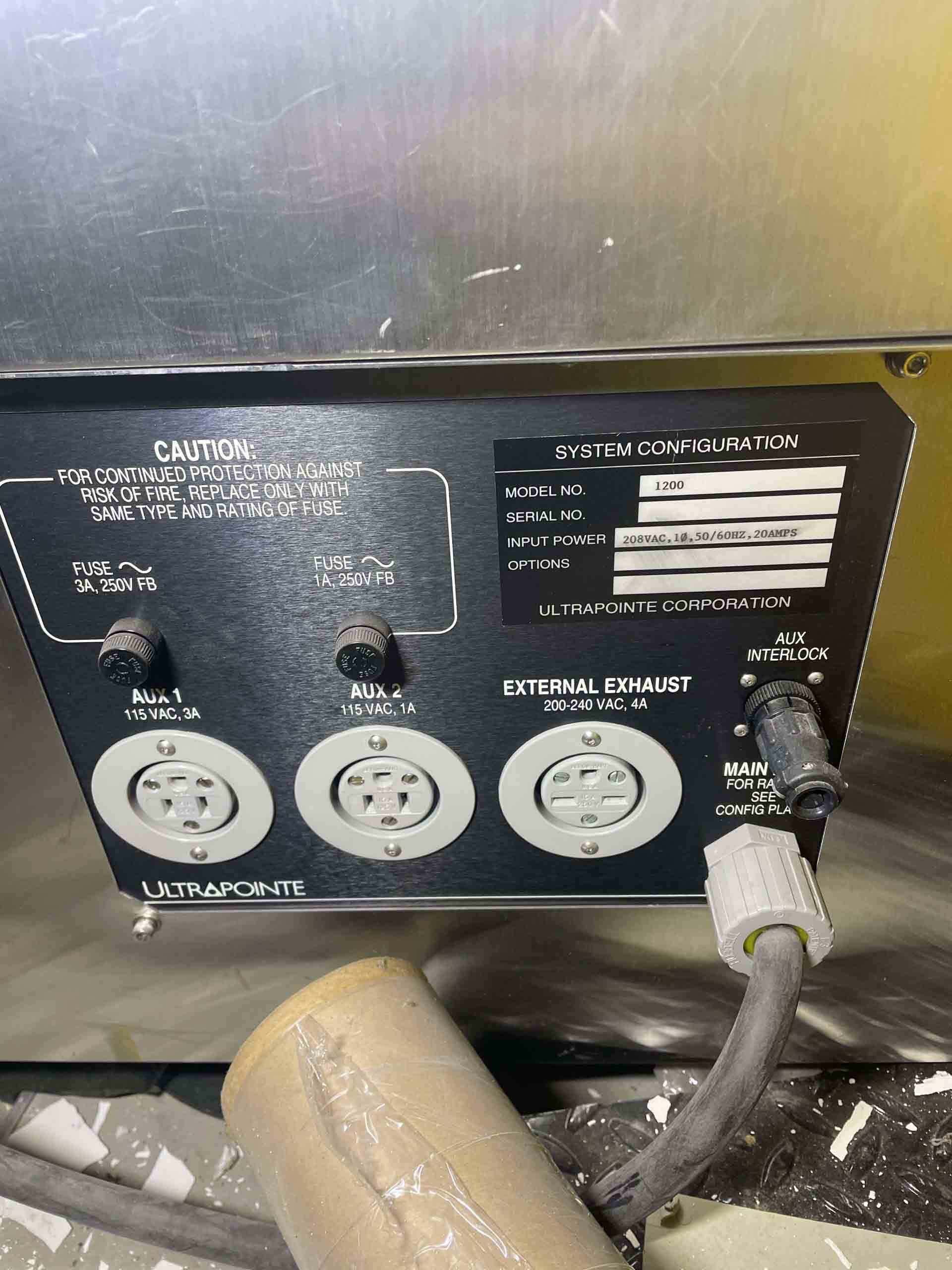

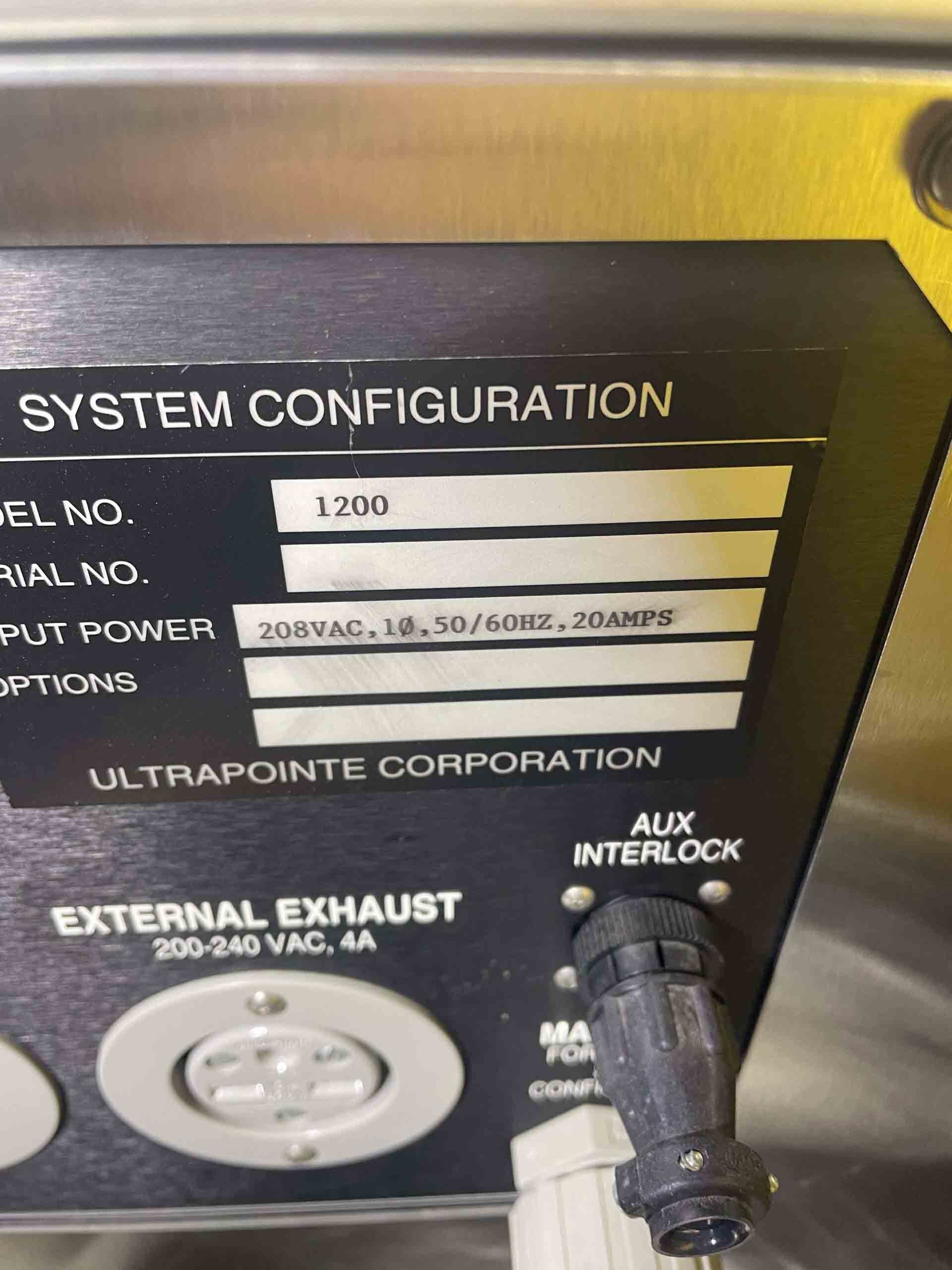

Used ULTRAPOINTE 1200 #9026312 for sale

URL successfully copied!

Tap to zoom

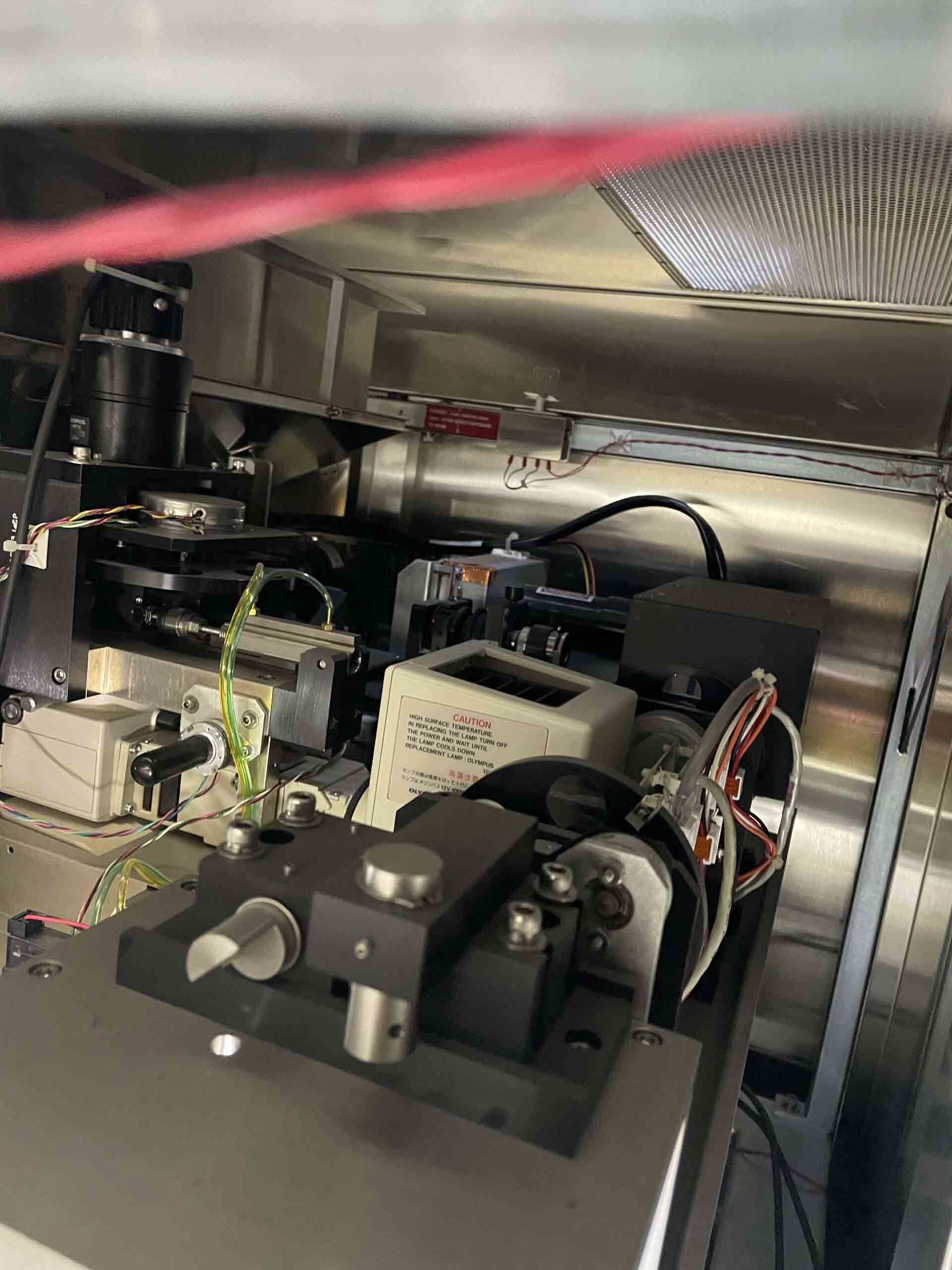

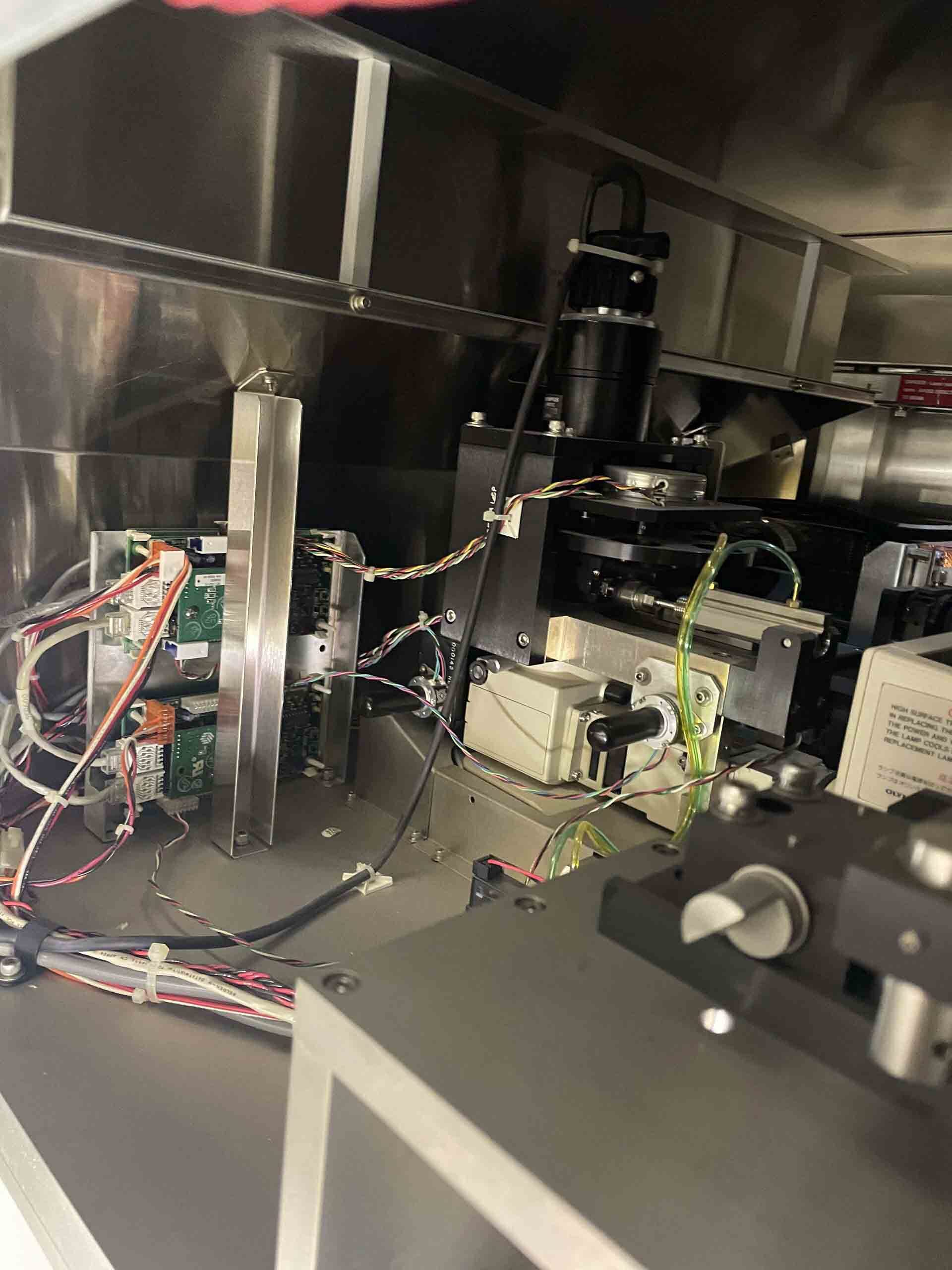

ULTRAPOINTE 1200 is a mask and wafer inspection equipment for integrated circuit fabrication processes. This system is designed for imaging and analyzing of photomasks used in the production of integrated circuits and wafer-level devices. The unit combines the latest imaging technology, sophisticated algorithms, and a user-friendly GUI for a comprehensive set of mask inspection functions. The imaging machine uses state-of-the-art charged-coupled device (CCD) cameras and optomechanics to accurately measure the quality of the mask patterns, identify print faults, and detect potential defects in-situ. The tool's proprietary algorithms then analyze the patterns for any features or defects that may present themselves. The results are then presented to the user in a highly-configurable GUI. 1200 is equipped with several features and tools to make sure that the masks and wafers being inspected are compliant and meet specifications. The asset is designed to work with various mask sizes and substrates, and can capture images up to 50 megapixels. The model can also measure and analyze a variety of print defects including line edges, contact holes, and vias. This data can then be used to either diagnose or modify the mask patterns, providing a powerful workflow tool that can save time and cost in the long run. The equipment also includes a variety of processing features and tools to further enhance its precision and accuracy. These include high-speed stitching, image enhancement, binarization, quantization, filtering, noise reduction, optical alignment, stage calibration, and ESD protection. All these features work together to ensure that the mask patterns and wafer features being inspected are properly captured and analyzed. In summary, ULTRAPOINTE 1200 is an advanced mask and wafer inspection system designed for identification of pattern defects and errors. Its sophisticated optical and processing capabilities, and its highly-configurable user-interface, ensure that the user can trust the results of their inspections in integrated circuit fabrication processes.

There are no reviews yet