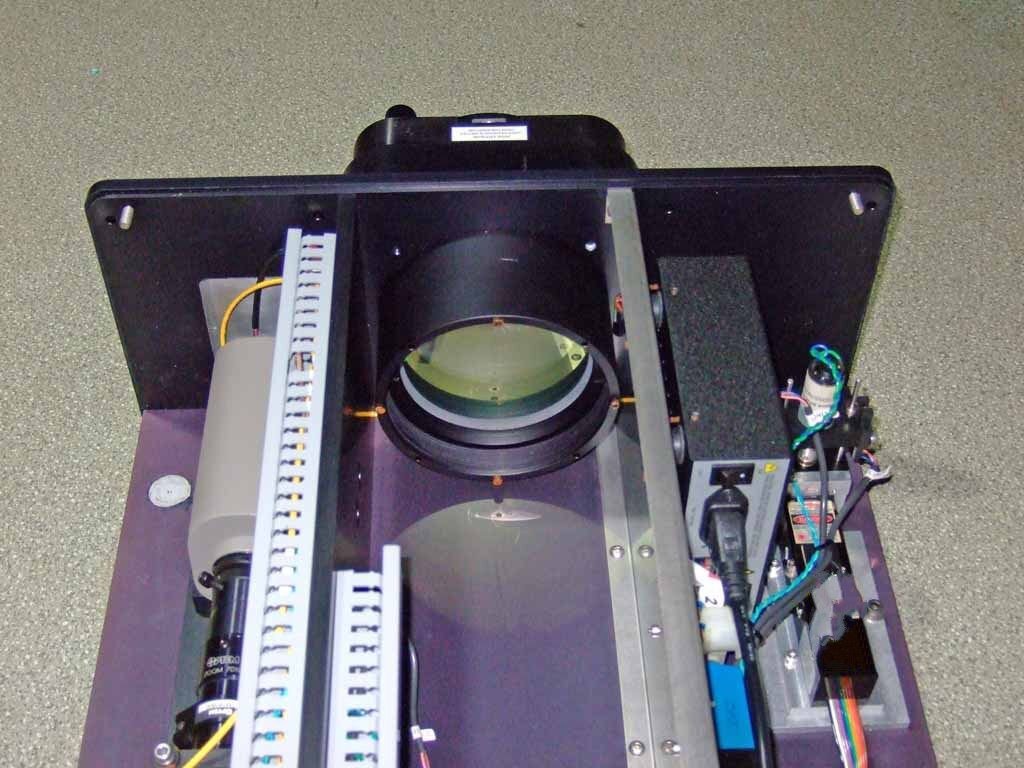

Used WYKO / VEECO RTI 4100 #9138179 for sale

URL successfully copied!

Tap to zoom

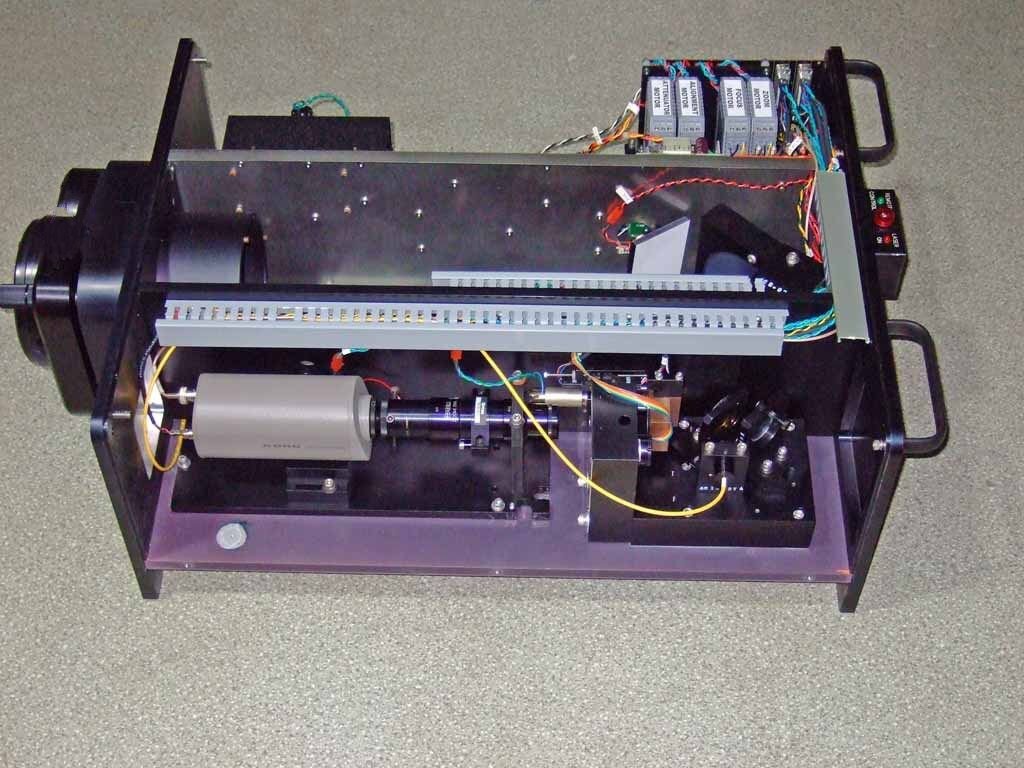

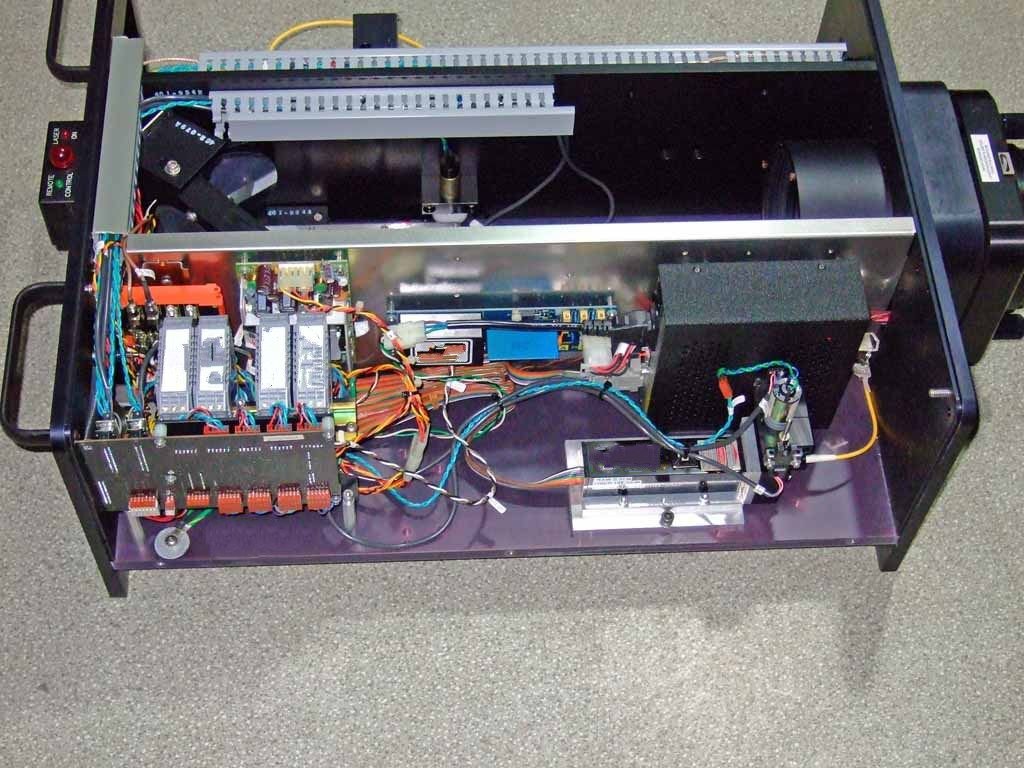

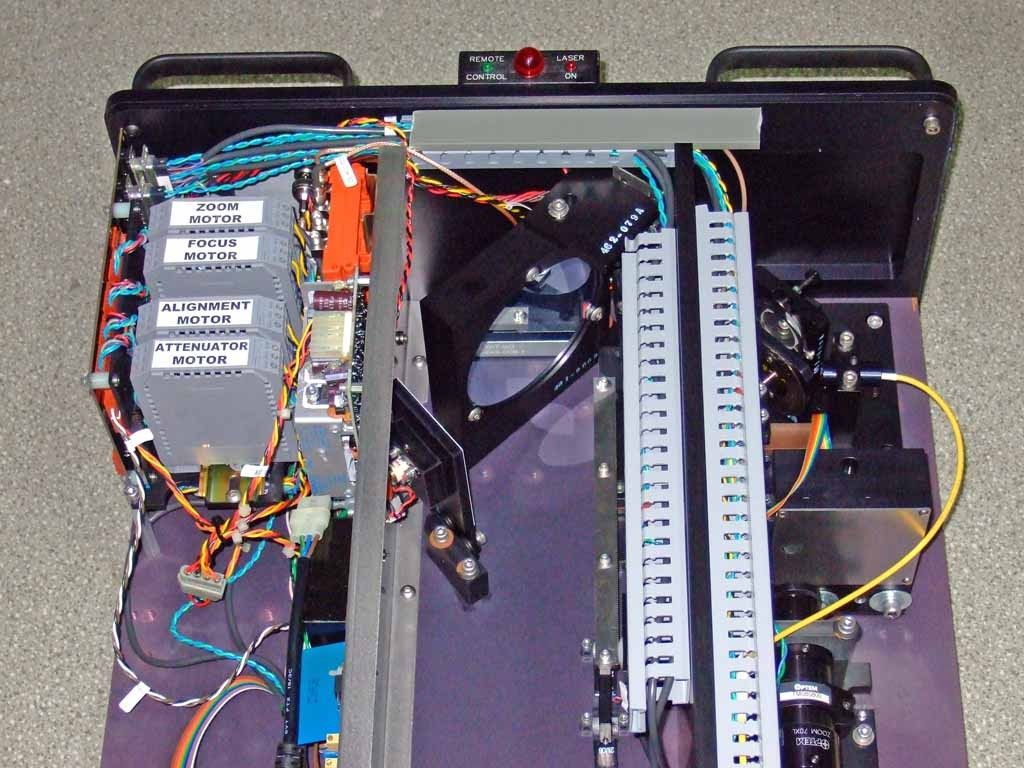

WYKO / VEECO RTI 4100 is a high-precision mask and wafer inspection equipment which combines multiple advanced technologies to provide extremely accurate imaging. This advanced system is used to create extremely accurate optical images of masks and wafers for the purpose of determining the size and shape of patterns that are created during the fabrication process. WYKO RTI 4100 utilizes optical imaging in order to image the mask or wafer with a high level of accuracy. This is done using an array of different technologies, including; pulsed laser and laser pulse shaping, scanning technology, high-resolution imaging, and dual spinning disc technology. This array of technologies results in a high resolution, repeatable, and accurate imaging process. VEECO RTI 4100 is capable of imaging a wide range of masks and wafers, from small to large, as well as different size patterns. The unit is equipped with a large range of software, allowing it to accurately compare patterns and determine the exact size and shape of each design. The data from the machine is also outputted in a wide range of formats, enabling it to be quickly analyzed and utilized by others downstream. One of the main benefits of RTI 4100 is its high level of accuracy and repeatability. The image created by the tool allows for the exact size and shape of each design to be determined quickly and accurately. This enables extremely efficient and accurate mask and wafer fabrication. The incorporation of multiple technologies in WYKO / VEECO RTI 4100 allows for a wide range of options when it comes to imaging. This allows users to customize the imaging techniques to fit their processor, as well as making it easier to compare and analyze the data. Additionally, the wide range of data output formats make the data accessible and easy to use downstream. WYKO RTI 4100 is an advanced mask and wafer inspection asset which uses multiple inherently accurate technologies to create a highly accurate and repeatable image. Its wide range of software and data output formats make it easy to compare and analyze the data, allowing for efficient and accurate mask and wafer fabrication. As such, it has become an invaluable tool in the manufacturing industry.

There are no reviews yet