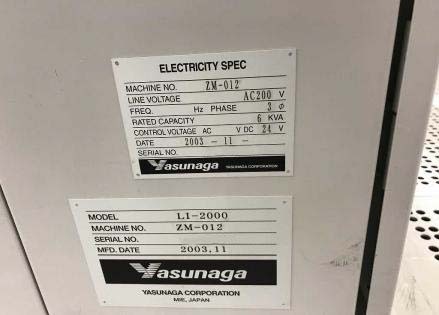

Used YASUNAGA LI-2000 #293654343 for sale

URL successfully copied!

Tap to zoom

YASUNAGA innovative YASUNAGA LI-2000 mask & wafer inspection equipment is designed to be the leading edge for precision imaging and inspection. The specialized hardware and software provides complete control and accuracy for a wide array of inspection requirements and increases efficiency in the mask and wafer inspection process. The system comes with a multi-directional compact design and a built-in library of extended features for inspection capabilities. LI-2000 combines various image acquisition software, inspection science and machine vision, along with advanced real-time processing capabilities. The intuitive interface and the on-board user guidance further facilitate the operation of the unit. With a state-of-the-art image processor and high-precision optics, YASUNAGA LI-2000 is able to detect and analyze defects at a high speed. The data acquisition can be automated, with the help of integrated sensors, and the machine can be connected to other external monitoring and analysis tools. LI-2000's advanced image analysis functions allow the detection of irregularities such as particle defects or scratches on substrates. OCR recognition and automated script-based operations are also possible which enhance the tool's efficiency. Furthermore, the artificial intelligence algorithms used by the asset promote defect detection for an absolute precision in the inspection process. The model consists of an advanced high speed lighting control, a micrometer stage, and a high speed X-Y stage with 16-bit intelligible control. This allows the user to acquire images with high resolution and fidelity from top, bottom and sides simultaneously. The user also has the capability of connecting to other external inspection systems, allowing for real-time data transfer and sharing. YASUNAGA LI-2000 achieves superior accuracy for precise mask and wafer inspection. It also enables faster fault detection, enhanced detection of defects, and minimal maintenance. With the integration with AI, OCR recognition algorithms and automated inspection processes, the equipment can be used for quality control and failure analysis. The versatile nature of the system further makes it the ideal choice for a variety of industries.

There are no reviews yet