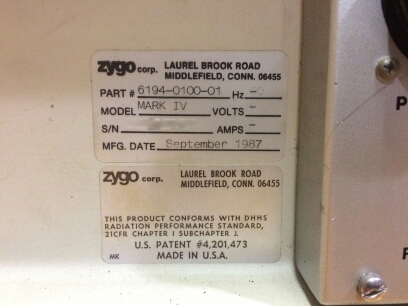

Used ZYGO Mark IV #9292128 for sale

URL successfully copied!

Tap to zoom

ID: 9292128

Vintage: 1987

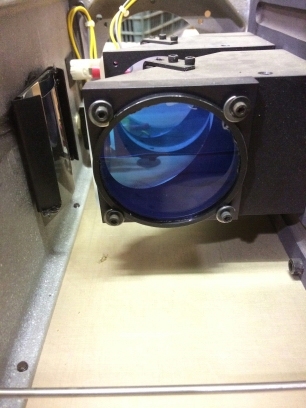

Interferometer

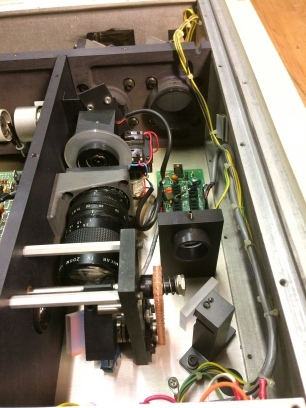

Wires

Camera

Remote

Missing parts:

Large system unit

Monitor

1987 vintage.

ZYGO Mark IV is a mask and wafer inspection equipment designed for use in semiconductor fabrication processes. It is an automated, multi-sensor inspection tool that provides comprehensive defect detection on a wide variety of materials. The system combines several advanced imaging techniques to provide users with unparalleled accuracy and resolution. Laser Interference Microscopy (LIM) is used to detect surface defects, while an advanced module called Automated Pattern Recognition (APR) is used to inspect masks and wafers for lithographic related defects. In addition, Defocus Sensitivity Imaging (DSI) is used to provide sub-micron detection of particles and small defects, while a Charge Coupled Device (CCD) camera is used to capture wide-angle, pattern-specific defects. This unit is also equipped with several user-friendly features, including automated defect classification and a detailed defect library. This library contains the measurements of previous targets, enabling quick and efficient inspection of similar targets. To further reduce errors and increase accuracy during defect reporting, the machine incorporates several defect-filtering algorithms, which can be adjusted to fit the user's inspection requirements. In terms of automation, Mark IV has features such as an Automatic Tool Centering process (ATC) and a Defect Split Tool (DST) that help to simplify the setup and operation of the tool. Additionally, the Automated Defect Mapping (ADM) tool is used to create a comprehensive defect density map that can be used virtually anywhere. The asset also offers a web-based reporting feature, allowing users to quickly and easily access defect-related data from a single screen. In addition to providing users with a comprehensive array of features, ZYGO Mark IV is also designed for continuous operation, ensuring maximum uptime and efficiency. The model also has a modular design that allows users to easily and cost-effectively upgrade their equipment as their inspection needs change. In conclusion, Mark IV is a comprehensive, automated mask and wafer inspection system that provides users with unparalleled detection accuracy and resolution. With its advanced imaging and defect-filtering capabilities, the unit is ideal for use in a wide range of fabrication processes.

There are no reviews yet