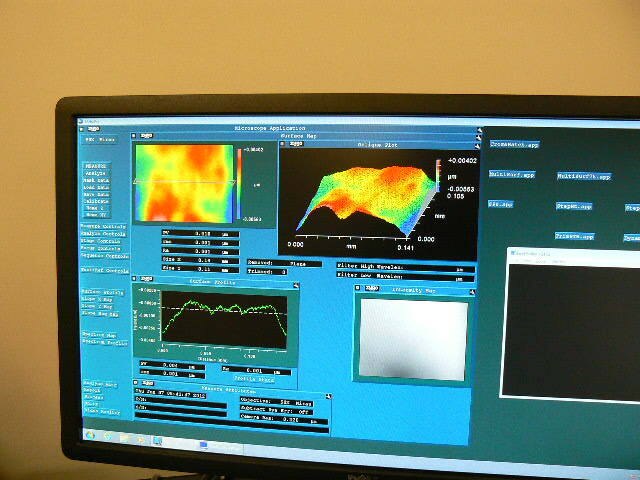

Used ZYGO NewView 5000 #9008672 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9008672

Interference Microscope

Dell PC installed by OEM

Win 7.0 and MetroPro 9.0.10

Includes:

(6) indexed positions of image zoom

Includes (3) objectives

Manual X/Y and tip/tilt stage with motorized Z-axis with turret

Includes vibration isolation table with workstation desk

Profile heights ranging rom >1 nm up to 5000 um at speeds up to 10 um / s with 0.1 nm height resolution, independent of magnifications and feature height

Variable image zoom

5-position manual or motorized turrets capability

Profile areas up to 50 x 50 mm and larger

Image stitching capabilities

Closed-loop prezo-based scanner

Highly-stable metrology

Ultra-rigid support structure

Granite base foundation

Reduced footprint dynamically stabilized vibration isolation table

Fully integrated ergonomic workstation

Gage capability

NIST-traceable standards

Interfaced to Pentium based PC

Password protection on applications

Various standard and optional automation modules

Programmable stages

Standard and custom sample fixturing

Integrated autofocus.

ZYGO NewView 5000 is a powerful mask and wafer inspection equipment for a range of inspection tasks. It enables front-side analysis for reticle and mask fabrication, and combines various imaging technologies including optical, SEM (Scanning Electron Microscope) and Raman spectroscopy, to facilitate multi-layer inspection. The system utilises innovative optical imaging technology which offers superior resolution and contrast imaging for both opaque samples and 3D structures. This allows for detection of micro-particles, defects and distortions, and enables high-precision imaging of materials down to the nanometre scale. ZYGO 5000 provides enhanced inspection capability through its state-of-the-art scanning electron microscope (SEM). This includes enhanced imaging resolution of up to 200 nanometres in real-time operation, and superior imaging resolution of 5 nanometres. This makes it ideal for inspecting high-resolution patterns and structures, as well as for achieving defect-finding and component-evaluation. The unit can also perform Raman spectroscopy (RS) to analyse material composition. This non-destructive technique is used for a variety of applications such as identifying foreign materials and contaminants, determining uniformity of deposition processes, and verifying layer changes. NewView 5000 also offers a comprehensive software suite which enables automated pattern recognition, complex image processing, and particle analysis. This intuitive software is able to detect and measure physical defects on wafers, reticles, and masks, as well as pattern variations for both opaque materials and 3D structures. The machine has a superior mechanical design which enables simple operation, loading and unloading of wafers, and sample changing. It also provides flexibility in handling substrates such as thick wafers, reticles, of varying shapes and sizes. 5000 offers the highest performance mask and wafer inspection capabilities available on the market today. It is an essential tool for ensuring the highest quality results in wafer fabrication to ensure accurate device performance.

There are no reviews yet