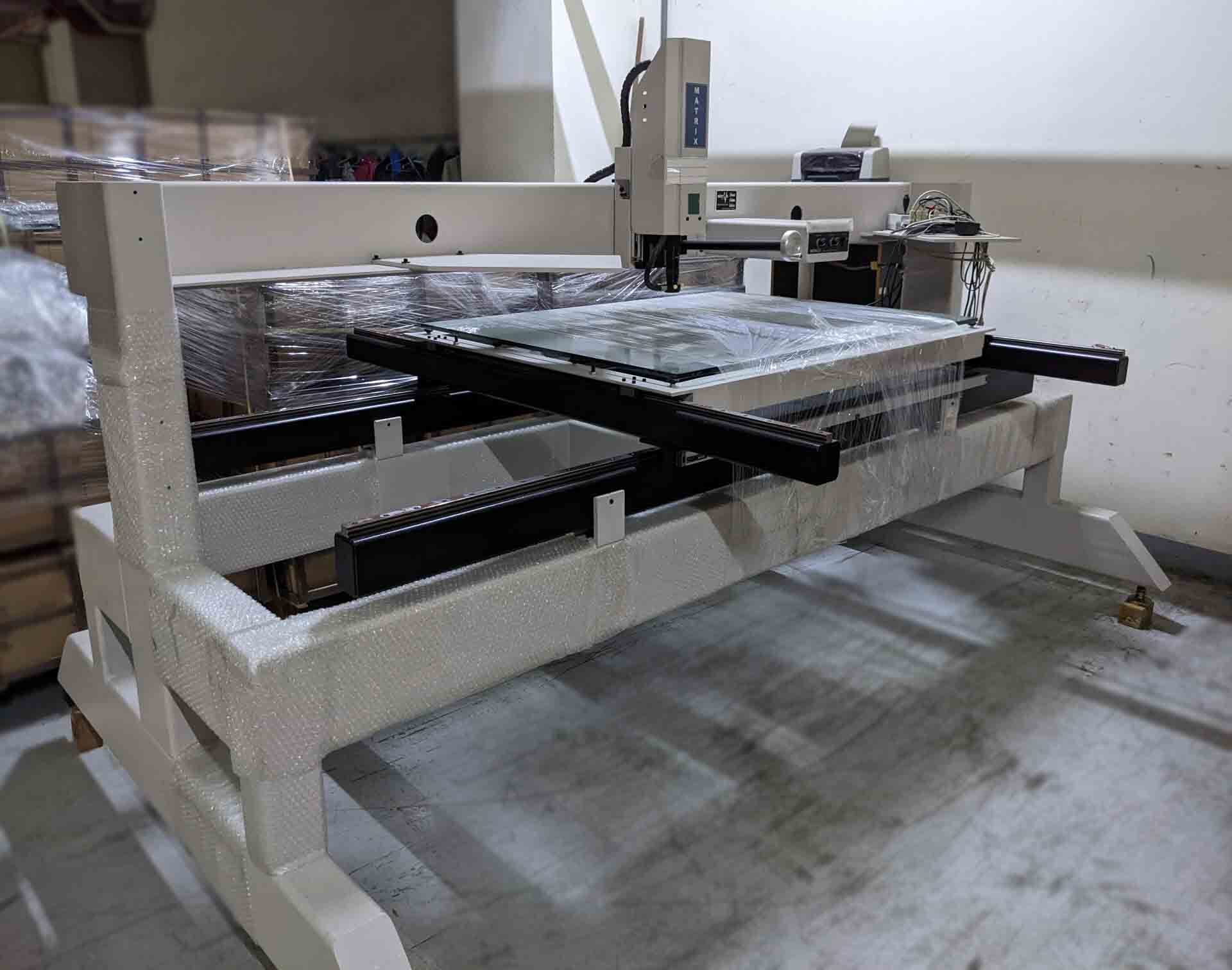

Used MICRO VU Matrix #293634682 for sale

URL successfully copied!

Tap to zoom

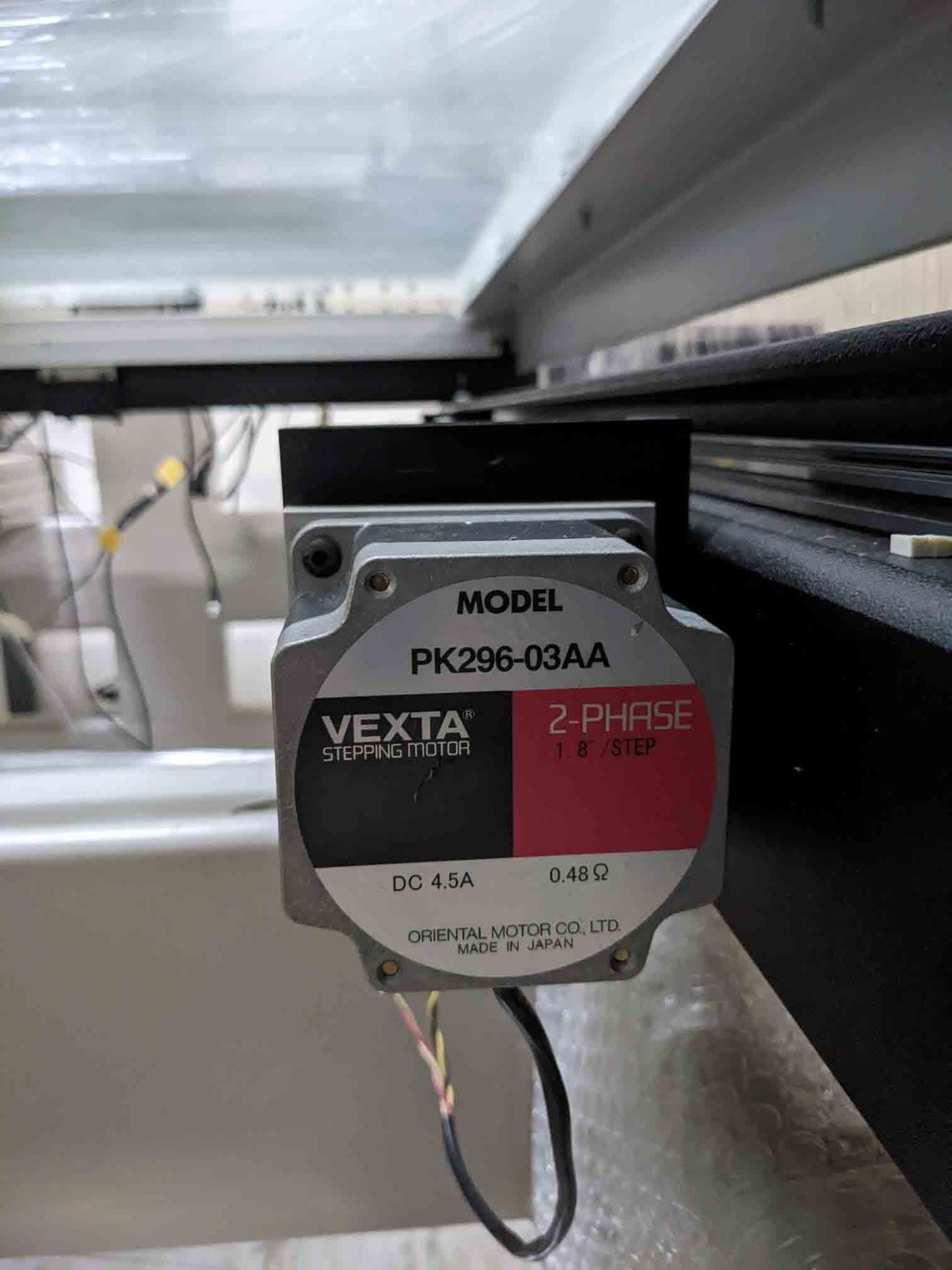

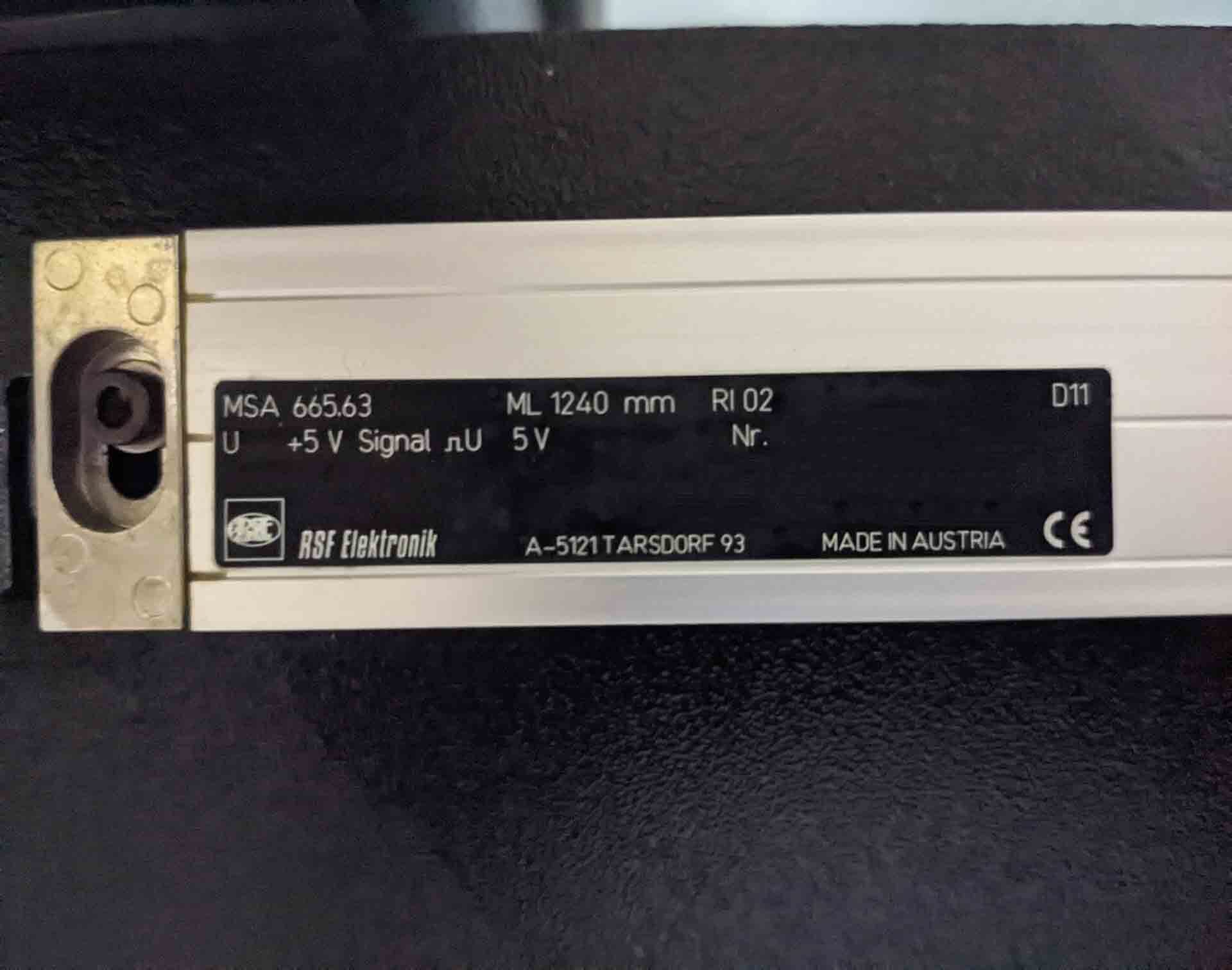

MICRO VU Matrix optical comparator is an optical measuring instrument used in industry to carry out precision measurements and inspections. It is used to measure parts, components and assemblies to preset tolerances and provides access to a range of measuring options. Matrix uses advanced optical technology to measure the size, form and position of objects, surfaces and features. It incorporates a projection equipment that focuses an image of the object onto a screen, using a high powered microscope, allowing very precise dimensional measurements to be taken. To measure axis locations, profiles and other features, a cross-check digital readout system is used in conjunction with a variety of probes and lens configurations. The computer control unit of MICRO VU Matrix is used to optimize contrast values, programs, magnification and measurement functions. This allows the scanning machine to maximize accuracy, speed and reliability in the inspection process. A range of statistical functions can be used to provide inspection results and run quality control metrics. The modern Matrix features enhanced image sharpness and contrast control, allowing it to detect finer features or surface errors. Continuous auto focus and depth of field capabilities further improve its efficiency. The instrument also has an open-architecture to allow integration into factory networks, as well as customizable software programs. MICRO VU Matrix meets a number of critical industry requirements, including inspection of products, assemblies and components. It can also be used to compare surface tolerances, compare prototypes against known standards and inspect a range of complex 2D and 3D shapes. The versatility of the instrument ensures it can be used in multiple industries, ranging from medical device manufacturing to the aerospace industry. Overall, Matrix is an advanced optical comparator that combines a range of modern features to improve accuracy, efficiency, and reliability in precision measurements and inspections. Its open architecture and customizable software programs make it a great choice for many industries looking to speed up their inspection processes.

There are no reviews yet