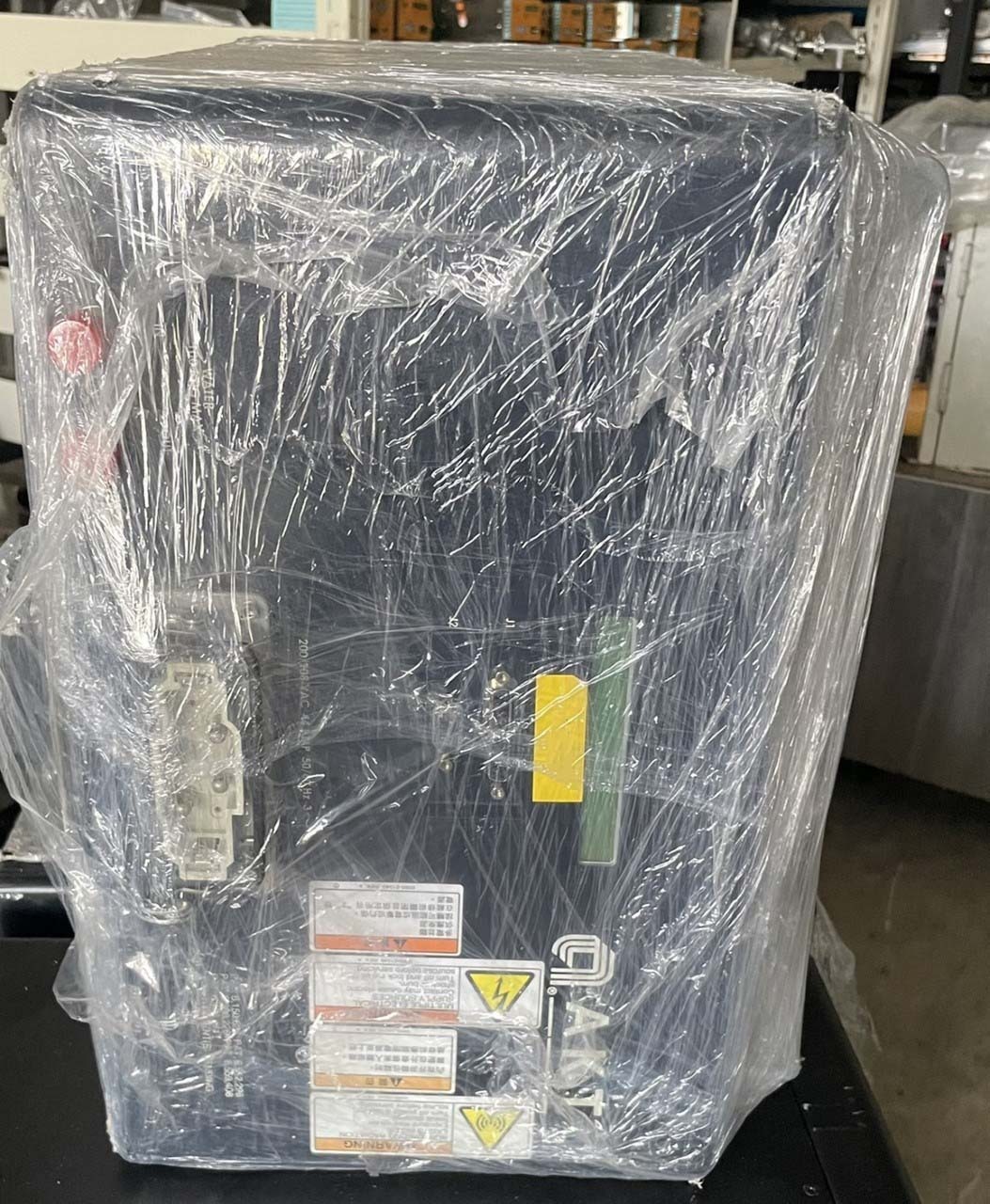

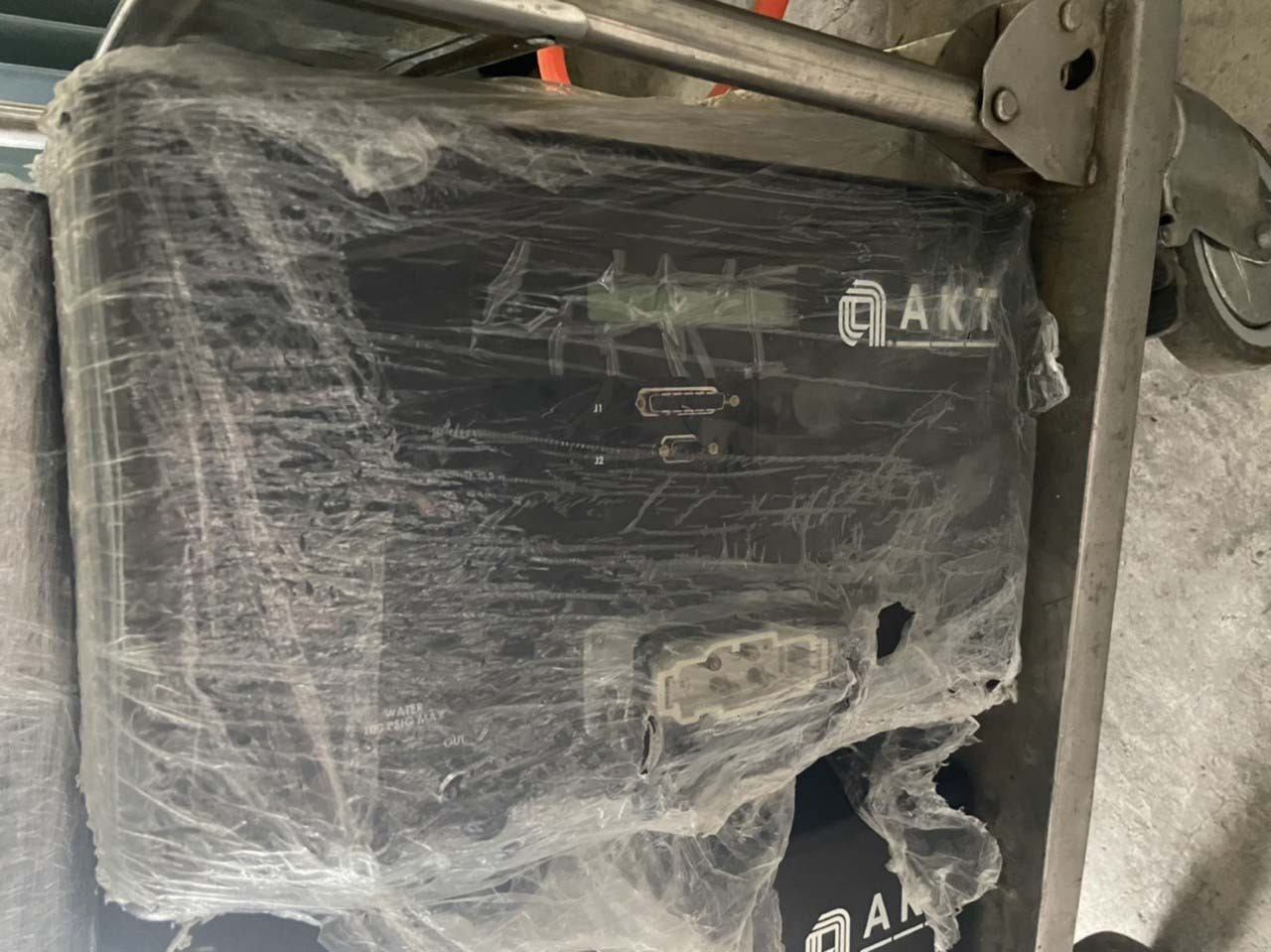

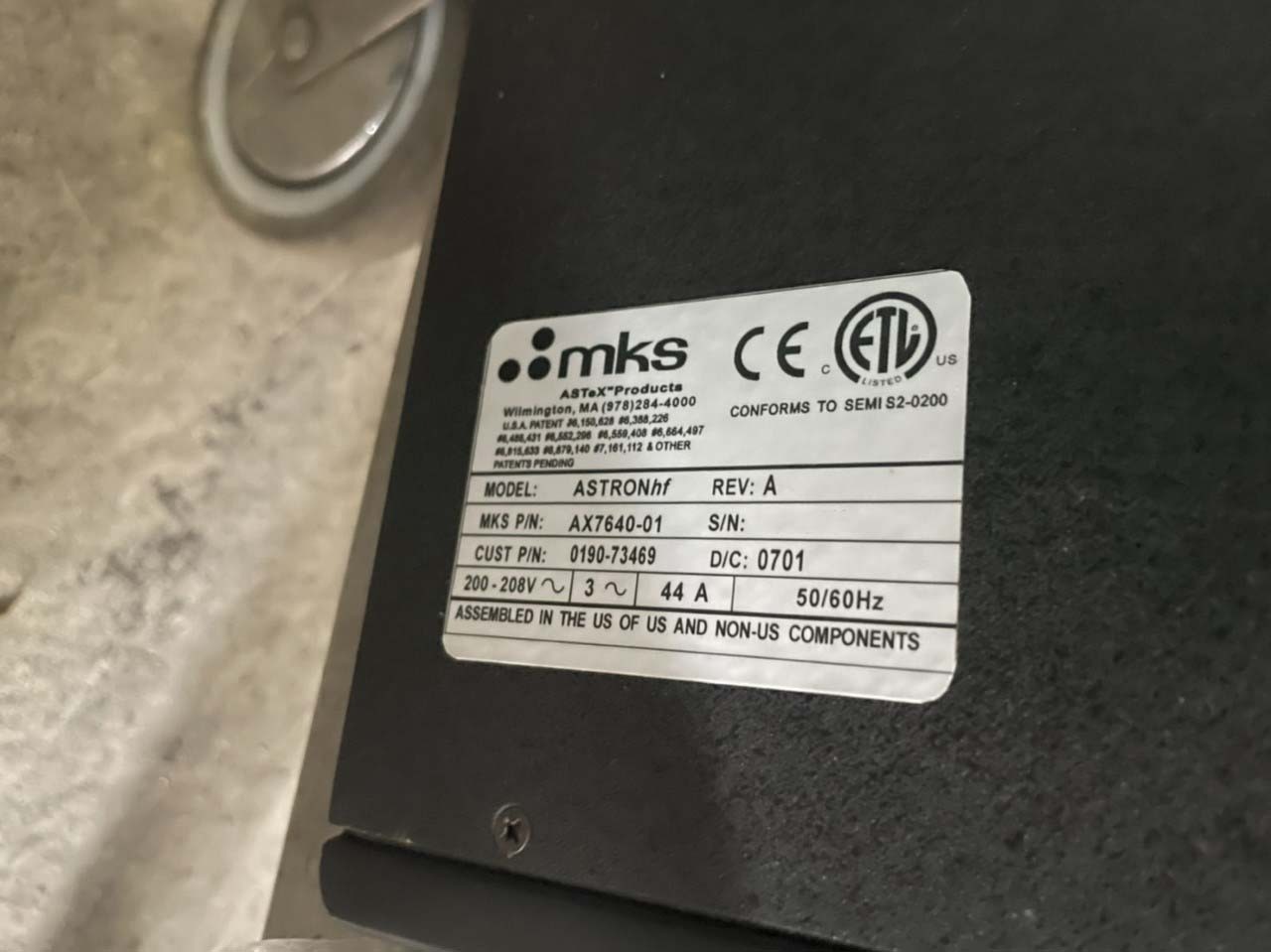

Used AKT / MKS Astron HF #293608418 for sale

URL successfully copied!

Tap to zoom

AKT / MKS Astron HF is an advanced wafer processing equipment for use in the production of high precision devices. It is specifically designed for double sided wafers, and offers a highly accurate and fast drying process. AKT Astron HF is equipped with a dual-laser wafer aligner, which is capable of accurately centering both sides of the wafer before processing. This ensures that the precision of the device is maintained throughout the production process. In addition, the machine is equipped with an on-board process controller which provides precise control over the parameters of the process. This includes oven temperature, air flow, pressure, and drying time. For wafer etching, MKS Astron HF also includes an advanced etching system. This uses a UV laser in order to accurately etch the wafers to a precise pattern or design. This etching is precise and precise etching is essential for forming highly accurate devices. Additionally, the etching unit can be adjusted to different conditions, such as depth, angle, and speed in order to create a variety of etch patterns. Astron HF also features an integrated clean room machine which allows for the production of extremely clean parts. This tool uses a filter asset to reduce the amount of particles which can reach the wafers, and this ensures that no contaminants are transferred onto the surface of the wafer. Furthermore, the entire model is designed to reduce contamination, while also keeping the entire production process clean and efficient. Finally, the equipment features a highly advanced automation system, which allows for rapid and accurate production of high precision devices. This automation unit can be fully customized in order to meet a variety of production needs, and is capable of running multiple jobs simultaneously in order to maximize efficiency. Overall, AKT / MKS Astron HF is an advanced and highly capable wafer processing machine, which is designed to produce high-precision devices. It offers a highly accurate and fast drying process, is equipped with a dual-laser wafer aligner, and has an integrated clean room tool which ensures low levels of contaminants on the wafers. In addition, the asset is equipped with a highly advanced automation model, which provides high speed and accuracy of production.

There are no reviews yet