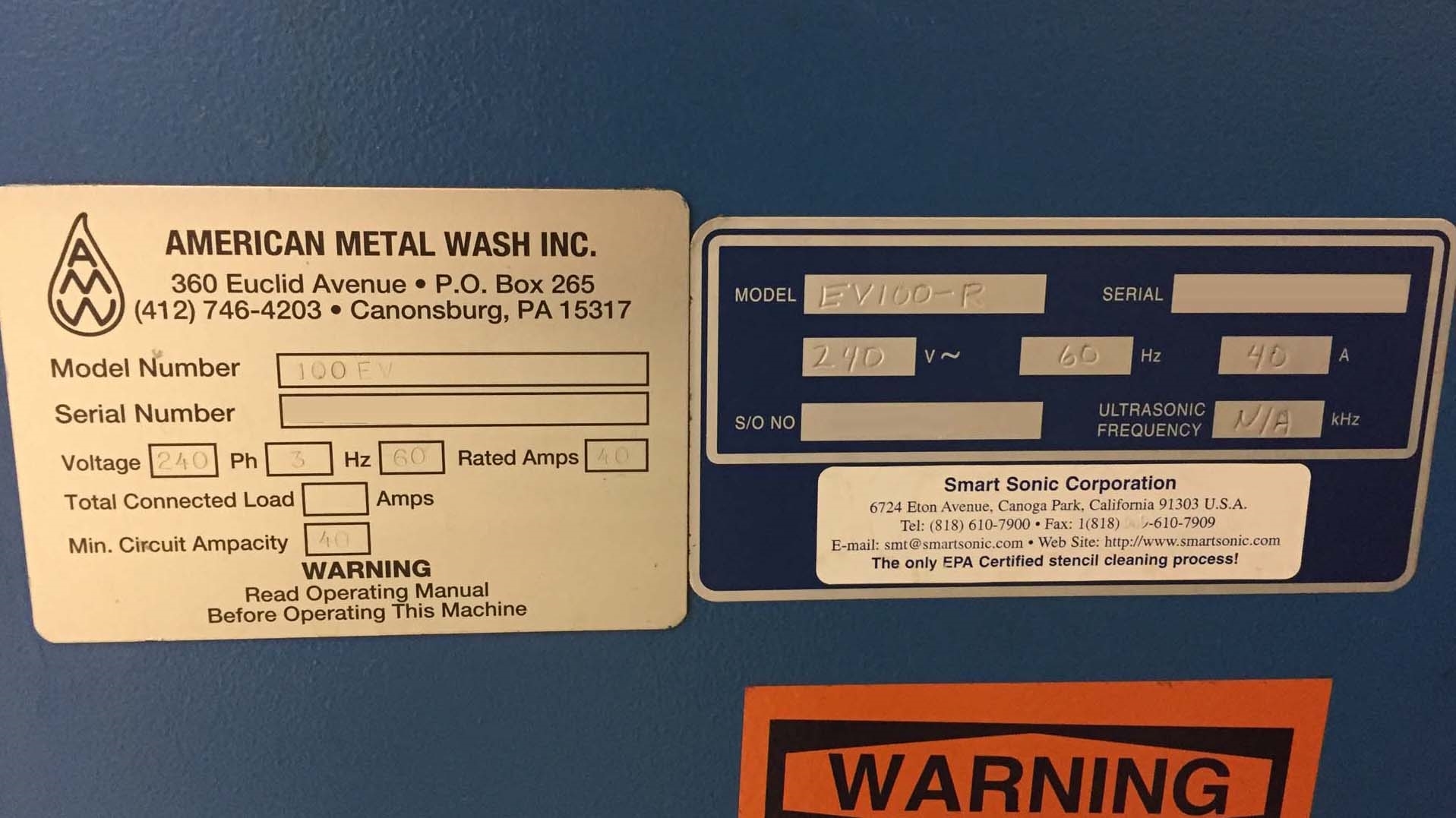

Used AMERICAN METAL WASH EV100 / EV100-R #9233519 for sale

URL successfully copied!

Tap to zoom

AMERICAN METAL WASH EV100 and EV100-R are wafer processing systems designed for a variety of semiconductor applications. The equipment utilizes a combination of chemical and thermal processes to clean, etch, and deposit desired materials to the wafer surface. The system is equipped with advanced robotics to facilitate quick and accurate placement and removal of wafers, while a full range of process controls allow users to adjust all elements of the process. The first component of the unit is the chemical process. This involves treating the wafer with a proprietary copper-base acid bath, which is specially designed to remove any unwanted contaminants and ensure up to a 25U oxidation-free surface finish. The machine is also capable of binary cleaning to enhance surface cleanliness. The EV100-R tool utilizes a robot-assisted process to reduce manual labor and improve efficiency. The second component of the asset is the thermal process. This uses a specially designed vacuum model to provide precise thermal control during wafer processing. The equipment is equipped with a temperature monitor and gas flow rate adjustment capabilities to ensure a controlled and consistent environment. In addition, the system offers active cooling capabilities to help prevent thermal damage to the wafer. The third component of the unit is the optional deposition capability. This uses advanced mask deposition technology to deposit various materials on the wafer surface. The materials can include diamonds, gallium nitride, and titanium nitride. This feature provides additional capabilities to the machine by allowing users to customize and enhance the properties of the wafer. AMERICAN METAL WASH EV100 and EV100-R are advanced wafer processing systems designed to produce high-quality components. The tool includes all the necessary components to clean, etch, and deposit desired materials to the wafer surface. The integrated advanced robotics and temperature and gas flow rate controls allow users to customize the process to achieve precise results. The optional deposition capabilities further expand the applications of the asset.

There are no reviews yet