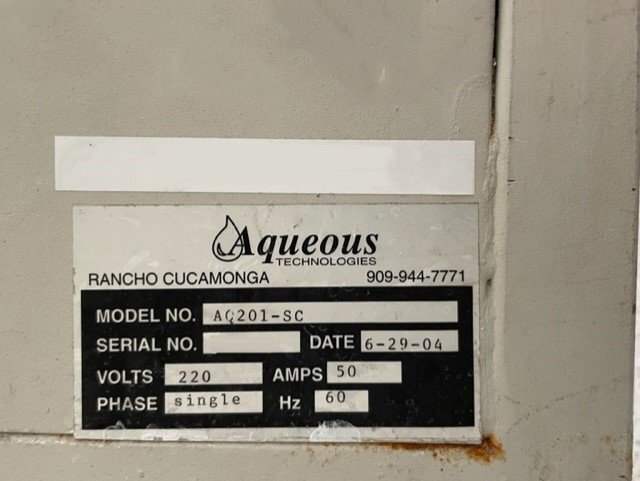

Used AQUEOUS TECH AQ 201SC #293590741 for sale

URL successfully copied!

Tap to zoom

AQUEOUS TECH AQ 201SC is a state-of-the-art other wafer processing equipment designed for large-scale production of complex semiconductor devices, such as System-on-Chip (SoC) devices, logic devices, and heterogeneous devices. AQ 201SC is a fully automated, single-wafer unit capable of performing a range of processes for a variety of wafer sizes. It is also capable of accommodating various substrate types, including Gallium Arsenide (GaAs) and Silicon on Insulator (SOI). The machine's core components consist of a wet processing module, a dry processing module,a cleanroom module, and a loading area. The wet processing module is capable of performing a variety of operations, including degassing, oxidation and etching, diffusion, wet cleaning, and chemical cleaning. The dry processing module is capable of performing chemical mechanical polishing (CMP) and other dry chemical processes. The 4-stage cleanroom module utilizes HEPA filtration to maintain cleanliness standards for production and also features an advanced chemical recipe management tool for both wet and dry processing. This allows for rapid optimization of recipes with minimal process operator intervention. In addition, an automated material loading asset allows for secure and accurate material handling. AQUEOUS TECH AQ 201SC features advanced visualization and data acquisition tools, such as the Process Analyzer and the Model Monitor. These tools allow the user to track and monitor the equipment's performance in real-time, allowing for immediate process optimization and troubleshooting. To accommodate the differing processing needs for a wide range of wafer sizes, the system includes various accessories, such as an exchangeable process frame, chuck, and a range of process chambers. Additionally, AQ 201SC can be customized to integrate with other production systems such as photolithography systems, CMP systems, and RTP systems. Finally, AQUEOUS TECH AQ 201SC is energy-efficient and meets the highest industry standards and environment regulations. This makes it a perfect solution for high-volume production and the demanding needs of modern semiconductor applications.

There are no reviews yet