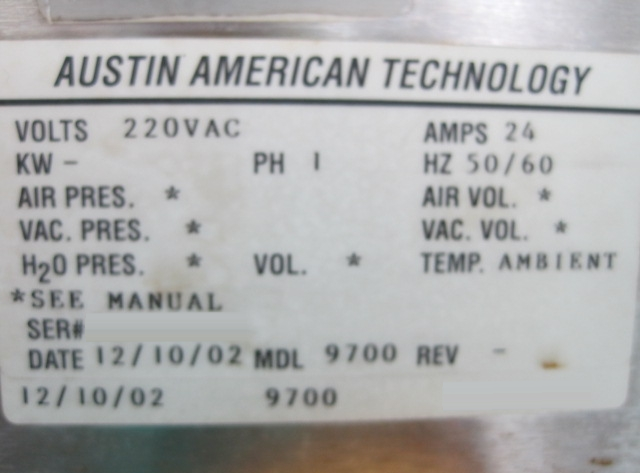

Used AUSTIN AMERICAN TECHNOLOGY / AAT 9700 #9082480 for sale

URL successfully copied!

Tap to zoom

ID: 9082480

Vintage: 2002

Emulsonator Semi-Aqueous Cleaning System

Maximum board size: 11 x 20 inches (28 x 51 cm)

Flow rate: 60 gallons per minute

Wash and rinse loop pumps: 2.5 gallons per minute

Stainless steel construction

Plumbing: stainless and teflon

Targeted for removing rosin flux from circuit boards

All-in-one system: wash, rinse, dry and waste treatment

Small footprint

60 GPM recirculations spray system and edge racking optimizes cleaing process

Closed-loop cleaning

Closed-loop rinsing

220 VAC, 24 Amps, 50/60 Hz

2002 vintage.

AUSTIN AMERICAN TECHNOLOGY / AAT 9700 is a fully automated wafer processing equipment that has been designed to help laboratories around the world better control and monitor the production of semiconductor materials. This is an incredibly powerful system and is designed to reduce production turnaround times, improve product yield, and maximize profits. At the heart of AAT 9700 is an advanced robotic unit that can carry out a variety of wafer processing functions, such as polishing, punching, slicing, and cutting. This machine is incredibly accurate and precise, ensuring that wafers have exactly the right dimensions for optimal performance. Additionally, AUSTIN AMERICAN TECHNOLOGY 9700 can be programmed to process multiple wafers simultaneously, increasing the yield from each production cycle. 9700 is also equipped with a comprehensive array of sensors that monitor all aspects of the wafer processing. These sensors measure all potential parameters, from temperature and pressure to humidity and air quality, so the environment remains consistent for each new production cycle. Additionally, the tool contains a database of recipes that allows scientists to easily configure the asset for a given set of parameters and optimize its performance. Finally, AUSTIN AMERICAN TECHNOLOGY / AAT 9700 is equipped with an easy-to-use interface that allows even a novice user to quickly configure the model to their needs. This includes setting all the related parameters as well as changing the robotic equipment's actions for specific wafer processing tasks. The user also has the ability to monitor and review the system's performance through real-time reports or by running manual tests. In conclusion, AAT 9700 is an incredibly powerful and sophisticated wafer processing unit that is capable of delivering precise results to manufacturers and laboratories alike. With its advanced robotic machine and comprehensive array of sensors and recipes, it is capable of significantly increasing wafer production yields while helping to ensure that each new production cycle is consistently successful. Finally, its intuitive interface makes it a breeze to both configure and monitor, allowing even novice users to make full use of its comprehensive capabilities.

There are no reviews yet