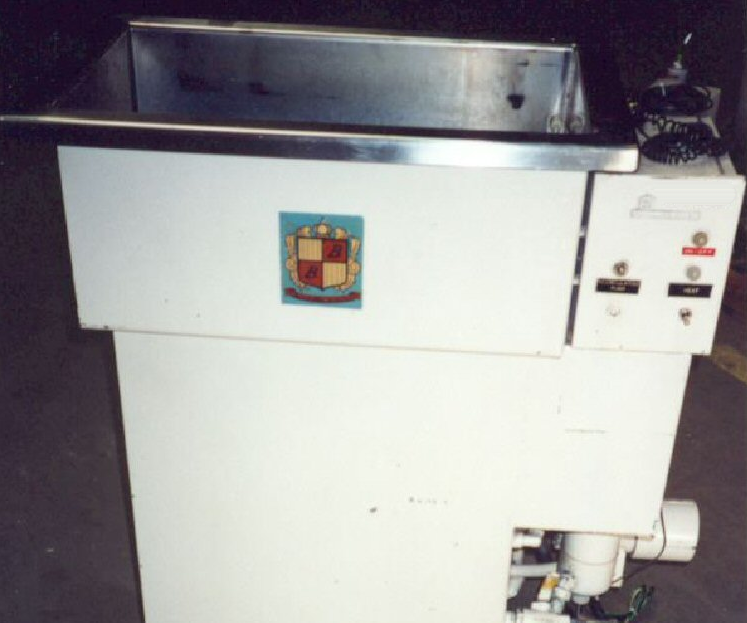

Used BARON BLAKESLEE MLR-120 #142292 for sale

URL successfully copied!

Tap to zoom

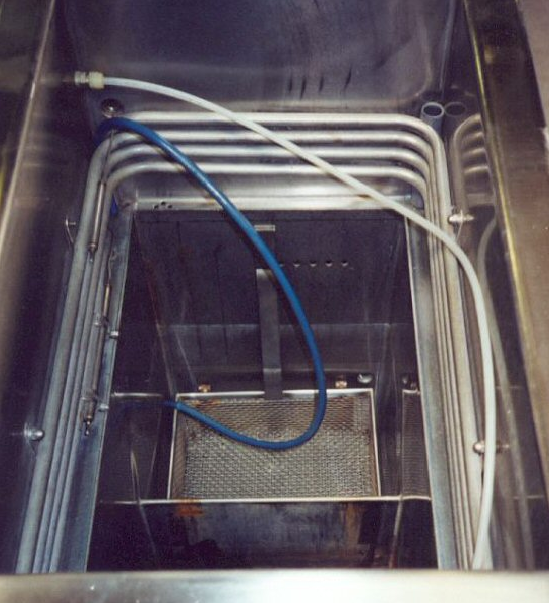

BARON BLAKESLEE MLR-120 is a state-of-the-art wafer processing equipment developed by Blakeslee Process Solutions and designed to provide precise and precise control of temperature, pressure, and other process conditions. The system is capable of supporting a variety of technologies, including photolithography, wet, annealing, spin-coating and other processes. MLR-120 is designed to create an ideal and customized environment for an array of processes. It offers a wide range of options for dynamic thermal and pressure control, allowing for single batch processing or multiple runs at different temperatures, pressures and times. It has an automatic vacuum overpressure unit, a built-in temperature controllers, and a wide range of standard temperature and pressure sensors. Temperature can be controlled from ambient up to 1000°C with a uniformity of +/- 1°C in a 10-inch or larger diameter area. Process pressure can also be adjusted from 0 to 10 Torr with a uniformity of +/- 1/2 Torr in a 10-inch area. BARON BLAKESLEE MLR-120 can also be individually configured to meet specific process requirements. It is constructed with heavy-duty stainless steel casings and chamber liners and robust stainless steel reaction baffles and trays. The removable stainless steel reaction chamber is designed to make processing easier. The chamber is vented through an exhaust port, allowing for a safe and efficient operation. Additionally, MLR-120 also offers advanced software control, which provides users with complete control over the machine. Through the software, users can easily control pressure, temperature, time, frequency and cycle parameters, including pre-programmed recipes and sequences to be used. The software also allows users to store process results, access production data and change parameters quickly to improve process performance. BARON BLAKESLEE MLR-120 wafer processing tool brings speed and accuracy to the processing of wafers for a variety of applications. Its wide range of features enable users to streamline their process, achieve reliable and repeatable results, and ensure optimal product quality.

There are no reviews yet