Used BOSTON 871010SPVB4J #293668929 for sale

URL successfully copied!

Tap to zoom

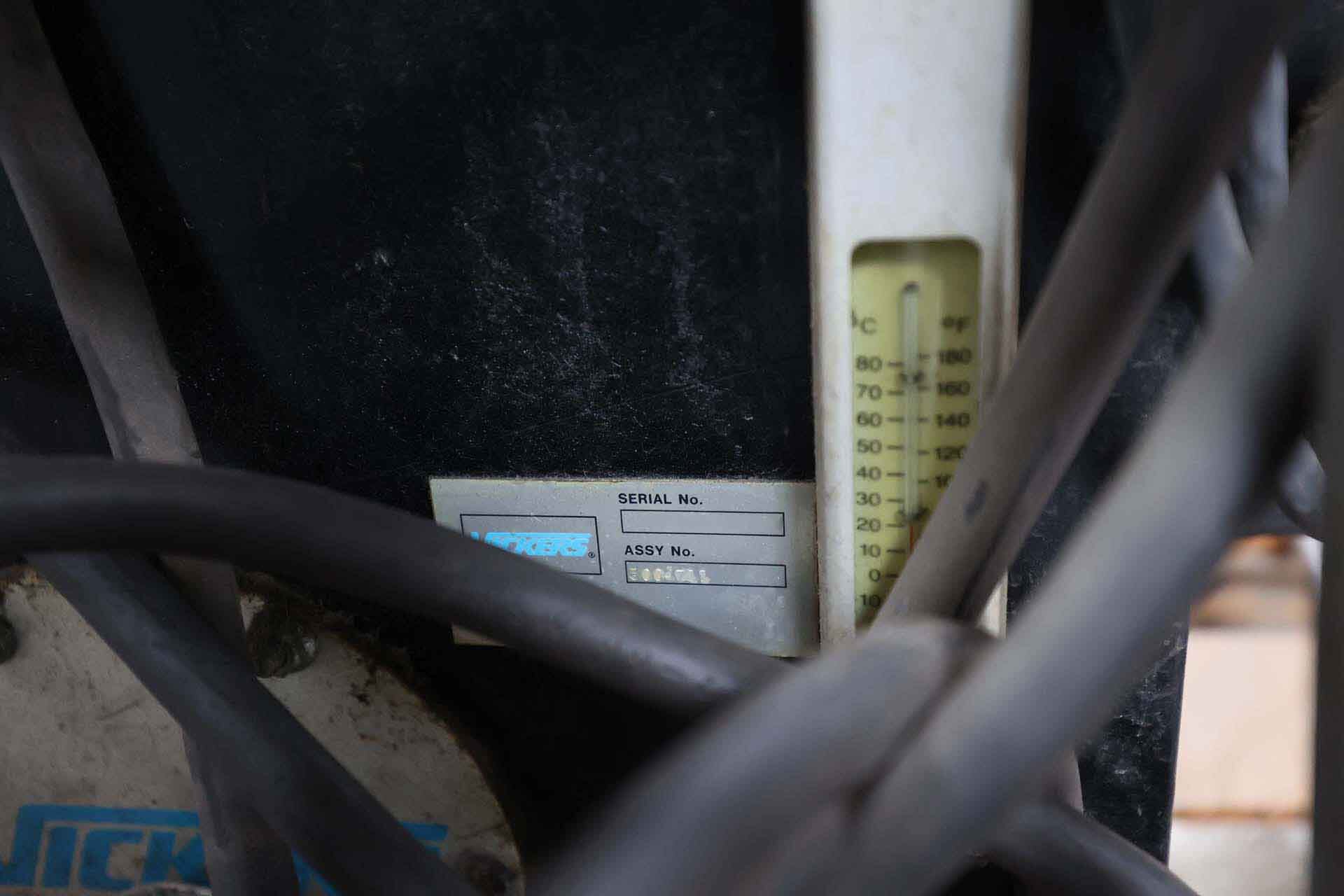

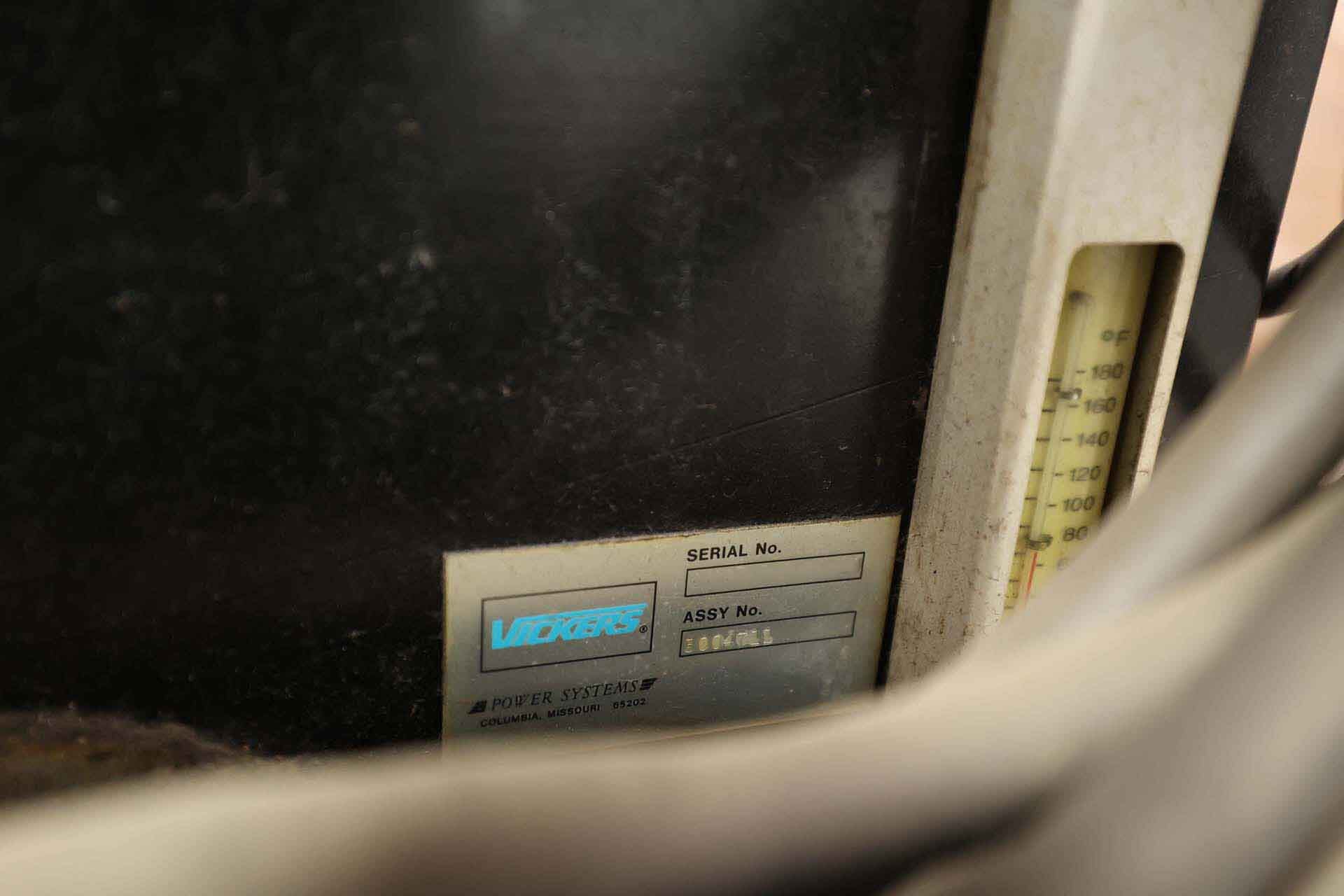

BOSTON 871010SPVB4J other wafer processing equipment is a photolithography tool used for precision processing of wafers. This system is designed for cleaning, resist coating, developing, etching, insulating, and other related wafer processes. The unit is built with a soft lapped top plate made of aluminum alloy that allows for the placement of wafers for processing. The processing unit has four brushes. These brushes rotate at different speeds for removing particles, and allow for uniform and consistent coatings of resist. The cleaning unit is designed to remove particles from the wafer. It is equipped with heated cleaning nozzles and an automatic ultrasonic transducer. The heated cleaning nozzles help remove stubborn particles from the wafers. The ultrasonic transducer is used to remove particles using a high-frequency sound wave. 871010SPVB4J has a built-in chemical management machine, which includes the addition of liquids and solvents during etching. It is equipped with an adjustable heating tool that allows for precise temperature control as required. A temperature sensor is also included to maintain an accurate temperature. The asset also includes a built-in photomask development model. This equipment uses light to create complex chip designs. BOSTON 871010SPVB4J is capable of processing up to four wafers simultaneously. Its maximum processing time is 200 seconds, and the minimum processing time is 20 seconds. It is designed to process wafers up to 12 inches in diameter and 12.99 mm in thickness. Additionally, its temperature range is 10-200 degrees Celsius, depending on the type of process requirements. The system has several safety features including a protection/protection board, an insulation unit, and a temperature sensor. The self-diagnosis machine ensure that the tool is running smoothly and that any potential problems are detected before they become major issues. Overall, 871010SPVB4J other wafer processing asset is an advanced tool used to accurately and precisely clean, resist coat, develop, etch, and insulate wafers. It is designed to support the manufactures of MEMS and other sophisticated electronic and communication products. Thanks to its superior temperature control, top plate design, and chemical management model, this equipment can save time, increase efficiency, and enhance the quality of the finished product.

There are no reviews yet