Used CHATTANOOGA GROUP TRITON 4739 #9398530 for sale

URL successfully copied!

Tap to zoom

ID: 9398530

Traction machine

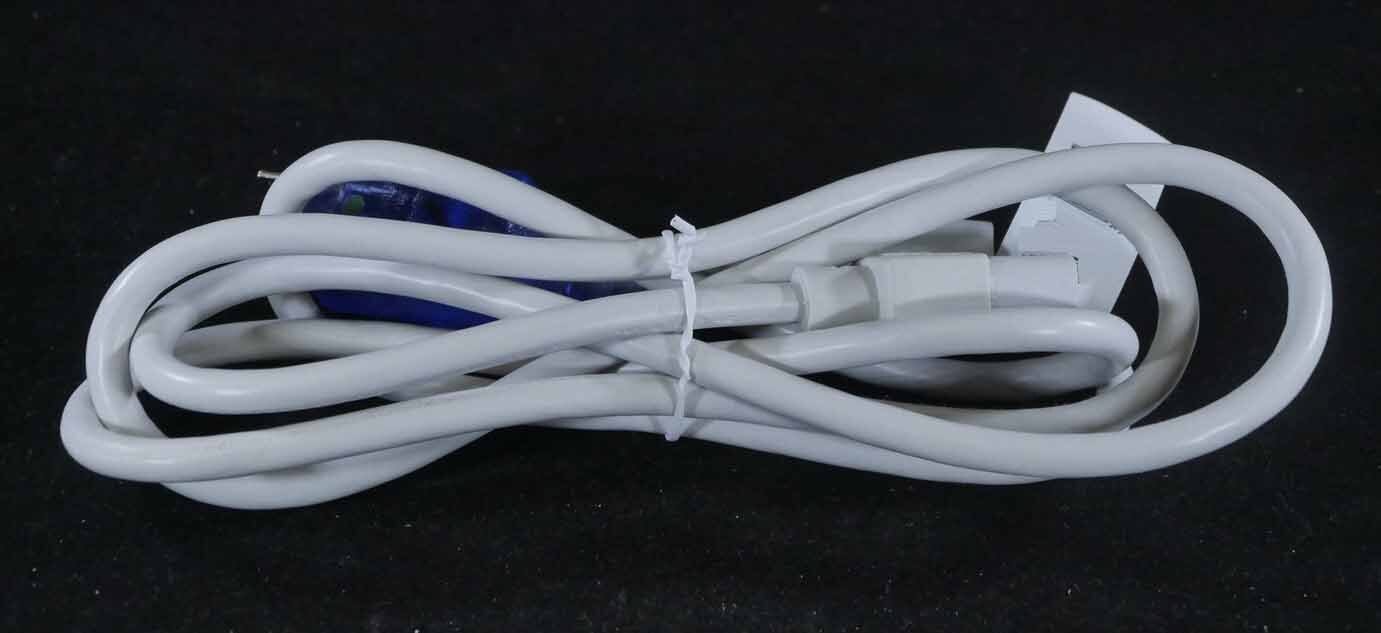

Power cord and controller included

Does not include accessories

Power supply: 100-240 VAC, 50-60 Hz, 75 VA.

CHATTANOOGA GROUP TRITON 4739 is a powerful and reliable equipment designed to provide efficient wafer processing and inspection for clients. The system is constructed to optimize every step of the wafer processing sequence and is ideal for applications that require a high degree of precision, such as IC production. The unit consists of two main modules: the Triton Processing station and the Triton Inspection station. The processing station allows for pre-cleaning of the wafers before etching, as well as wet and dry etching processes. This ensures that the wafers are completely clean prior to the inspection process and that all contaminants are removed. The Triton Inspection station is where the wafers are examined for defects. The machine is designed with a cutting-edge optical inspection module and a wafer visual identification tool. The asset is capable of detecting defects in electronics and electrical materials, as well as in microlithography. The model offers many features to improve the efficiency and accuracy of the wafer processing. The Triton 4739 features an advanced robotic handling arm which ensures the accuracy of sample placement and automated sample movement. Additionally, the equipment can be programmed to reduce human errors, thus optimizing production quality. The system also integrates a number of innovative technologies which contribute to the high quality of the wafer processing. The unit includes an air purification machine to reduce contamination during the entire wafer process. Additionally, the Triton CHATTANOOGA GROUP TRITON 4739 can perform quick and accurate wafer recognition and sorting through a unique vision-based algorithm. This algorithm enables the tool to identify defects and classify them according to their size, shape and other characteristics. 4739 is a powerful asset that provides the quality and precision necessary for advanced IC production. This model has the unique ability to process and inspect wafers in an efficient and precise manner, which saves both time and resources for manufacturers.

There are no reviews yet