Used COBRA YCL-2110 #293643804 for sale

URL successfully copied!

Tap to zoom

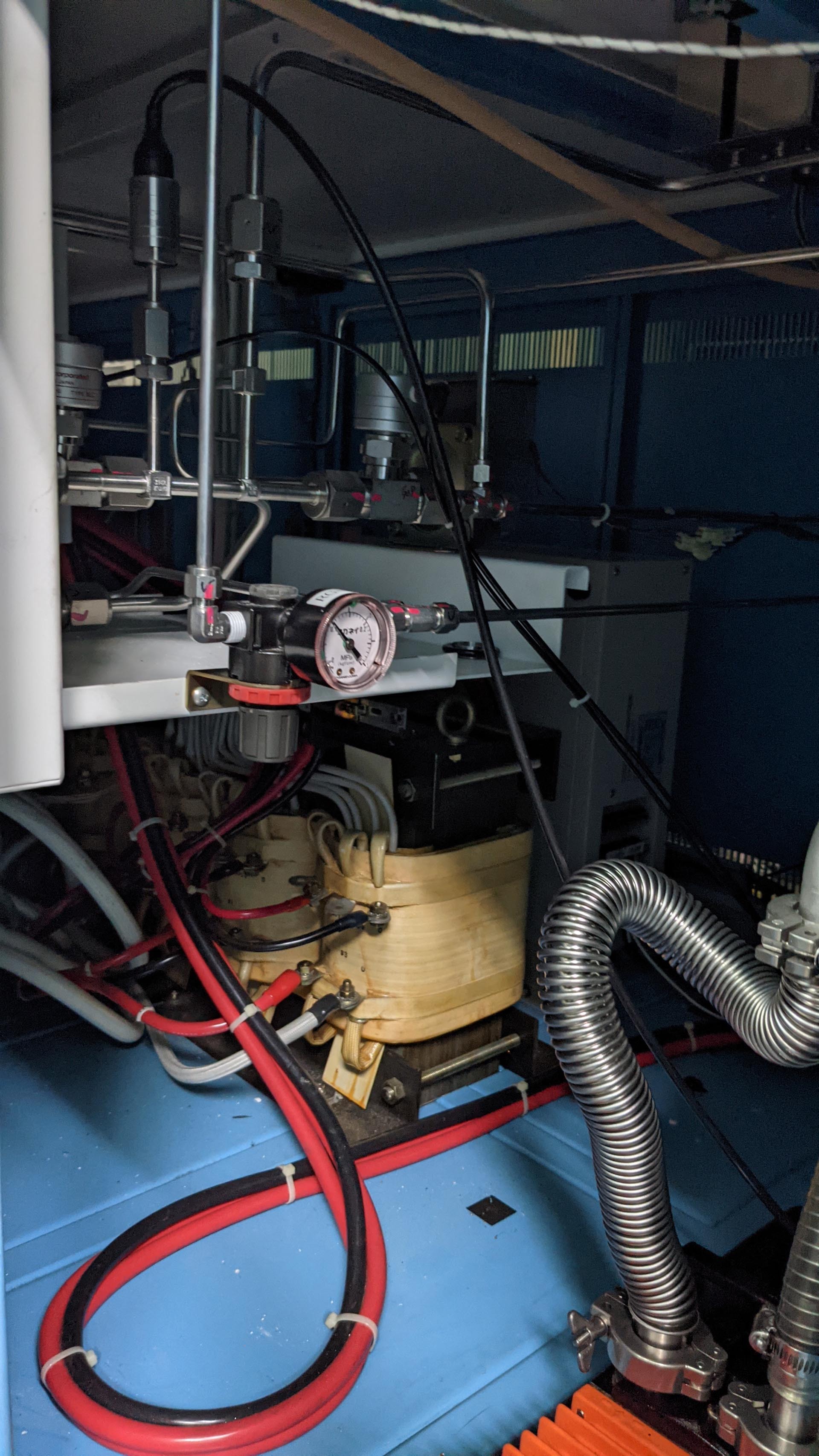

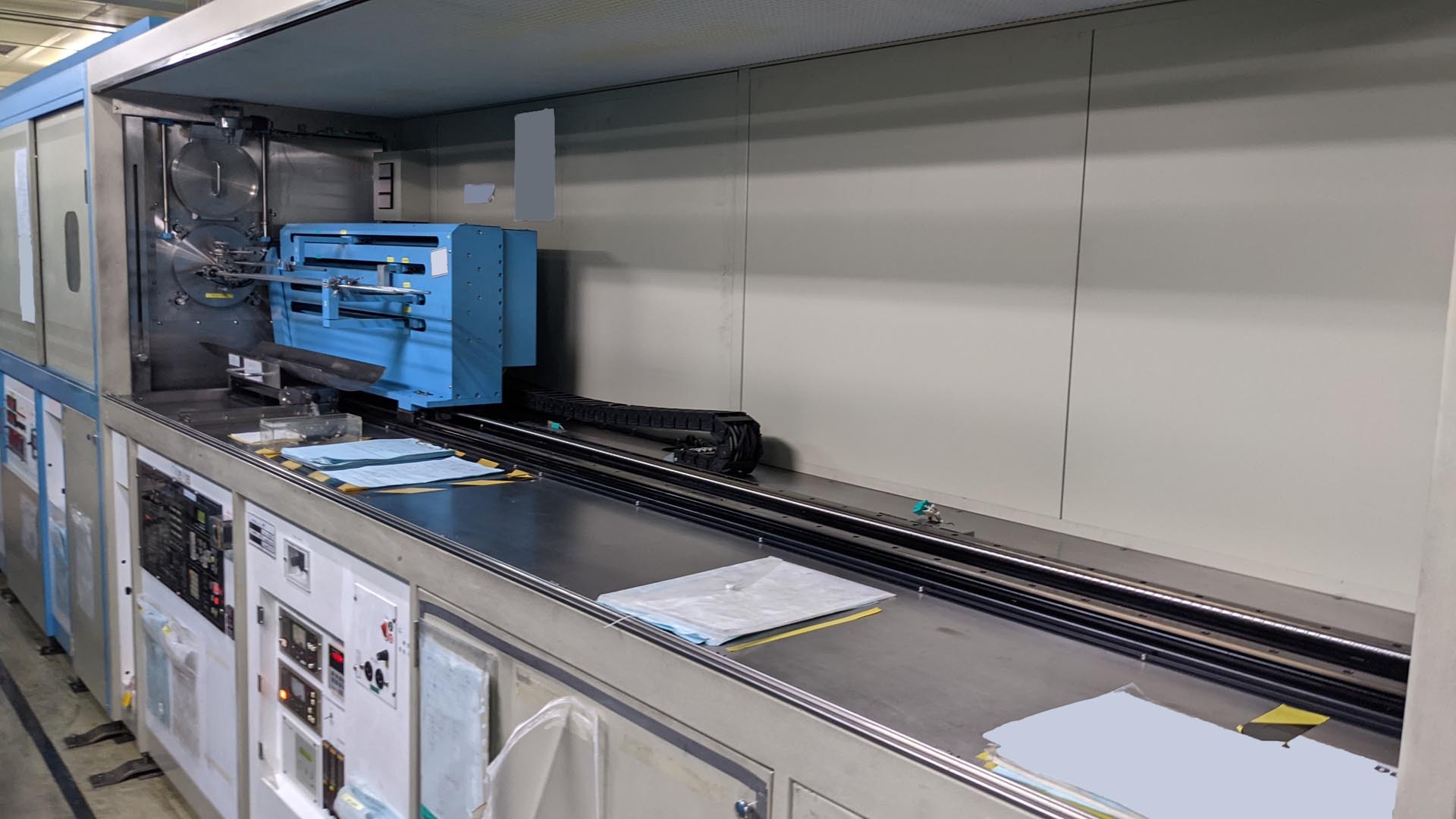

COBRA YCL-2110 is a comprehensive wafer processing equipment designed for high throughput of wet and dry processes. It can be used for a variety of applications ranging from textile to optical products. The advanced PEEK polymer port plate technology ensures repeatability and accuracy with every process. This enables the user to achieve exact requirements in terms of size, shape, and uniformity. The machine is equipped with a reliable, high-precision, and efficient robotic unit. The arm is equipped with positioners, vision systems and edge detection sensors that enable accurate and repeatable operations. These features allow the user to reliably and accurately process the wafer at high speeds. The machine also features an end-of-arm tooling system (EOAT) to accommodate different types of process applications. These include front and backside processing, cleaning, polishing, and annealing. The EOAT unit is designed to reduce downtime and optimize performance. It also offers low-cost flexible processing options. Furthermore, high speed wafer holders enable users to manage larger processing runs more efficiently. The holders contain gripper arms with vacuum cup pickups to ensure secure and repeatable placement of the wafers. The machine is also equipped with state-of-the-art vision and alignment systems. These enable users to accurately measure, position and orientate a wafer relative to the robotic arm. This ensures a repeatable and accurate process. Finally, the optional wafer exit machine provides complete wafer tracking, safety, and process control. This allows users to know exactly when and which wafers have been processed. In summary, YCL-2110 utilizes advanced technology to provide a reliable, accurate and efficient wafer processing tool for high throughput assembly.

There are no reviews yet