Used CREST 4HT-710-3 4G-500-6 #47526 for sale

URL successfully copied!

Tap to zoom

ID: 47526

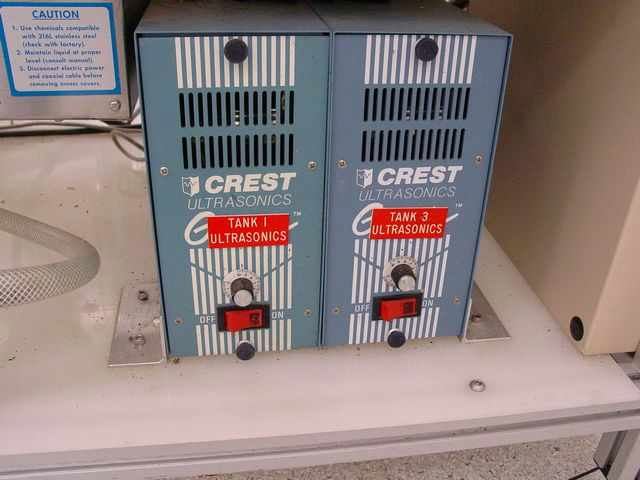

Wet Bench, 2 Each Ultrasonic Tank Generator

Tank Dimension Effective 6" x 6" x 6"

Two Ultrasonic Tanks - Two Rinse Tanks

Tank PN 4HT-710-3-0F1 - 2 Each

Generator PN 4G-500-6-P - 2 Each

Break-Out Box with Controller

Siemens Simatic T1315 DD.

CREST 4HT-710-3 4G-500-6 is a state-of-the-art wafer processing equipment designed to meet the developing needs of modern electronics production. This production-level system is an ideal choice for 3D wafer process operations such as deep trench etching, lithography, and other forms of wafer manufacturing. The unit utilizes a versatile dual robot co-axial wafer loading toolset. This feature allows the machine to simultaneously hold two wafers while loading and unloading operations are performed. This feature drastically speeds up loading/unloading times and allows for simultaneous processing of multiple wafers. This makes it an ideal choice for high-volume production runs. 4HT-710-3 4G-500-6 is equipped with a breakthrough plasma etch combination tool. This asset combines inductively-coupled plasma (ICP) etching and reactive ion etching (RIE) capabilities. This allows for rapid and precise surface modification. Further, this combo model allows for deep trench etching without compromising etch quality. This makes it one of the most efficient systems on the market today. CREST 4HT-710-3 4G-500-6 also features a vertically-aligned lithography toolset. This setup allows for precise wafer alignment during lithography operations. This ensures that critical features are accurately printed. Further, this vertical setup increases consistency from wafer to wafer. This is especially important for intricate applications such as microelectromechanical systems (MEMS). Finally, the incredible throughput capacity of 4HT-710-3 4G-500-6 is one of its defining features. This equipment can process 500 wafers per hour. This is made possible by a combination of factors such as the dual co-axial wafer loading toolset and the combined plasma etch combo system. This puts CREST 4HT-710-3 4G-500-6 on the forefront of wafer processing systems. In summation, 4HT-710-3 4G-500-6 is a powerful and advanced wafer processing unit that is designed to meet the needs of modern electronics production. This machine is ideal for high-volume production runs and offers cutting-edge etching and lithography capabilities. Further, this tool has an impressive throughput capacity of 500 wafers per hour. This makes it an ideal choice for any business looking to streamline their production lines.

There are no reviews yet