Used CREST Optimum #9131750 for sale

URL successfully copied!

Tap to zoom

ID: 9131750

Wafer Size: 10"

Ultrasonic precision cleaning system, 10"

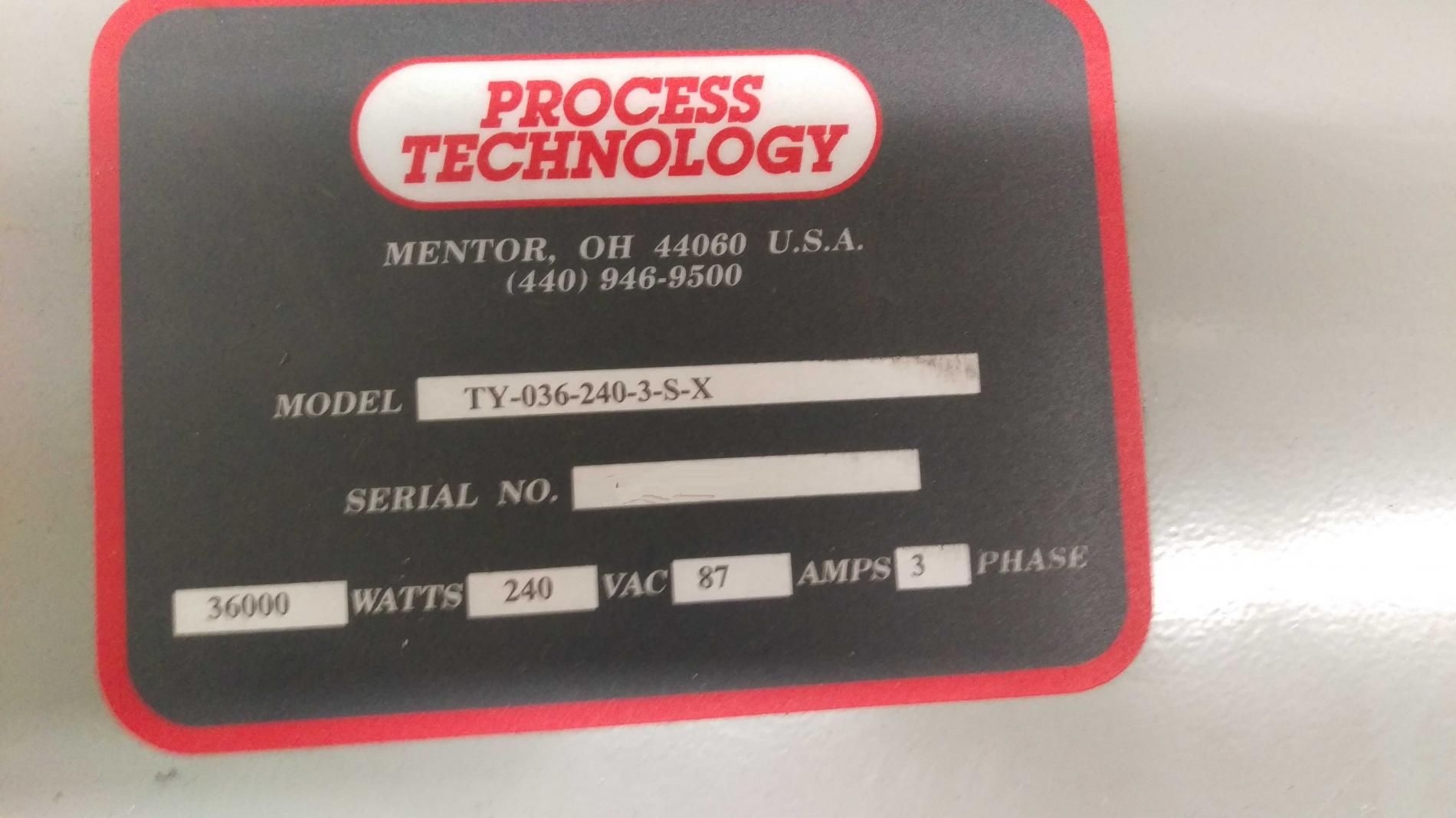

With DI water heater

Ultrasonic wash tank with overflow

Spray rinse

Spray over ultrasonic Immersion rinse tank

Cascading spray

Ultrasonic immersion rinse tank

Hot air dryer (hepa filtration)

Tank 1:

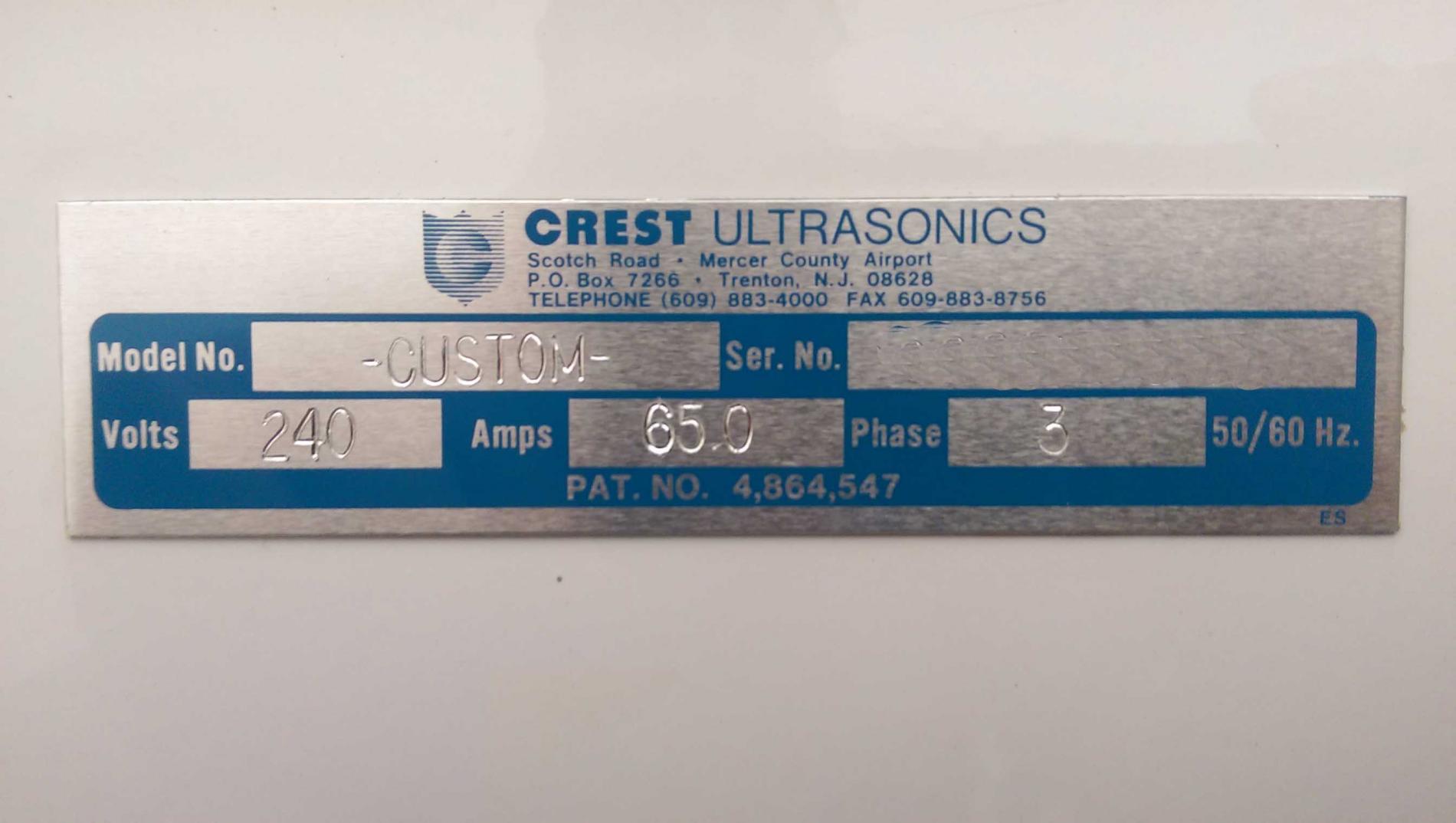

Ultrasonic generators (Crest Unit)

(2) 500W, 68 kHz

Crest genesis

Model 6G-500-G-T

Tank 2:

(2) 500W, 132 kHz

Powersonics

Model MW500 GTV / 132

Tank 3:

Has power supply

Transducers installed

Wired as for Powersonics

(2) Plug in generators.

CREST Optimum is a state-of-the-art wafer processing equipment designed to provide optimal performance for silicide fabrication and other semiconductor applications. It is comprised of a suite of hardware and software systems, including a robotic workstation, a loadlock system, and a number of advanced process modules. The unit provides high throughput, maximum flexibility, and precise control over all wafer fabrication processes, ensuring that customers can produce products of the highest quality and reliability. The robotic workstation of the machine forms the core of Optimum tool. It is equipped with advanced automation capabilities, allowing for high-speed loading and unloading of wafers without manual intervention. This workstation is designed to support up to 12 process modules for a variety of applications, including cleaning, metrology, and etch processes. Additionally, its integrated safety interlock systems protect the asset's operator from hazardous situations. The model is also equipped with a loadlock equipment that provides access to an environment separated from the main chamber. This allows for samples to be accurately and efficiently loaded into the chamber of the robotic workstation. The loadlock system includes an integrated vacuum unit as well as an inert-gas delivery machine for controlling the atmosphere within the chamber. CREST Optimum tool also incorporates a number of advanced process modules. Its amorphous silicon module enables precise crystallization of thin films at high throughputs, while its chemical mechanical polishing (CMP) module offers ultra-smooth surfaces for fabrication applications. Additionally, its epitaxy module provides fast-track fabrication of compound semiconductor devices, and its rapid thermal annealing (RTA) module provides advanced heating and cooling capabilities that enable high-speed throughput performance. In addition to its hardware capabilities, Optimum asset comes equipped with a comprehensive software suite that facilitates advanced monitoring and control of the model's process modules. This includes a built-in recipe manager that allows users to create and store custom recipes for fabrication processes, as well as a process data acquisition and logging equipment that provides a comprehensive view of the system's performance in real-time. CREST Optimum unit is designed to provide an optimal solution for a wide variety of wafer processing applications, offering superior performance, maximum flexibility, and unparalleled precision. Its feature-rich suite of hardware and software systems transforms the process of creating complex semiconductor devices, allowing customers to achieve unprecedented results in a cost-effective manner.

There are no reviews yet