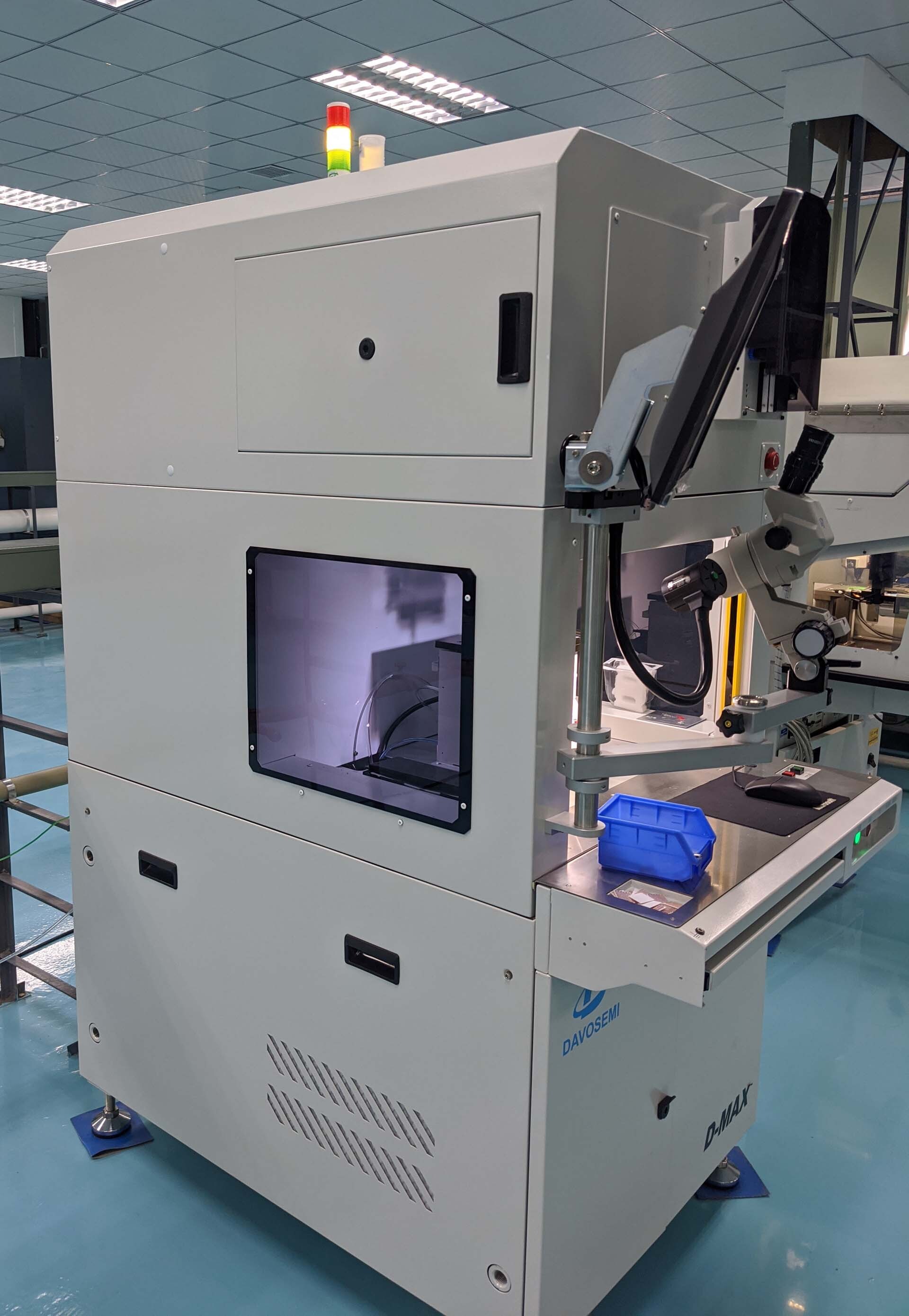

Used DAVOSEMI D-MAX #293654966 for sale

URL successfully copied!

Tap to zoom

ID: 293654966

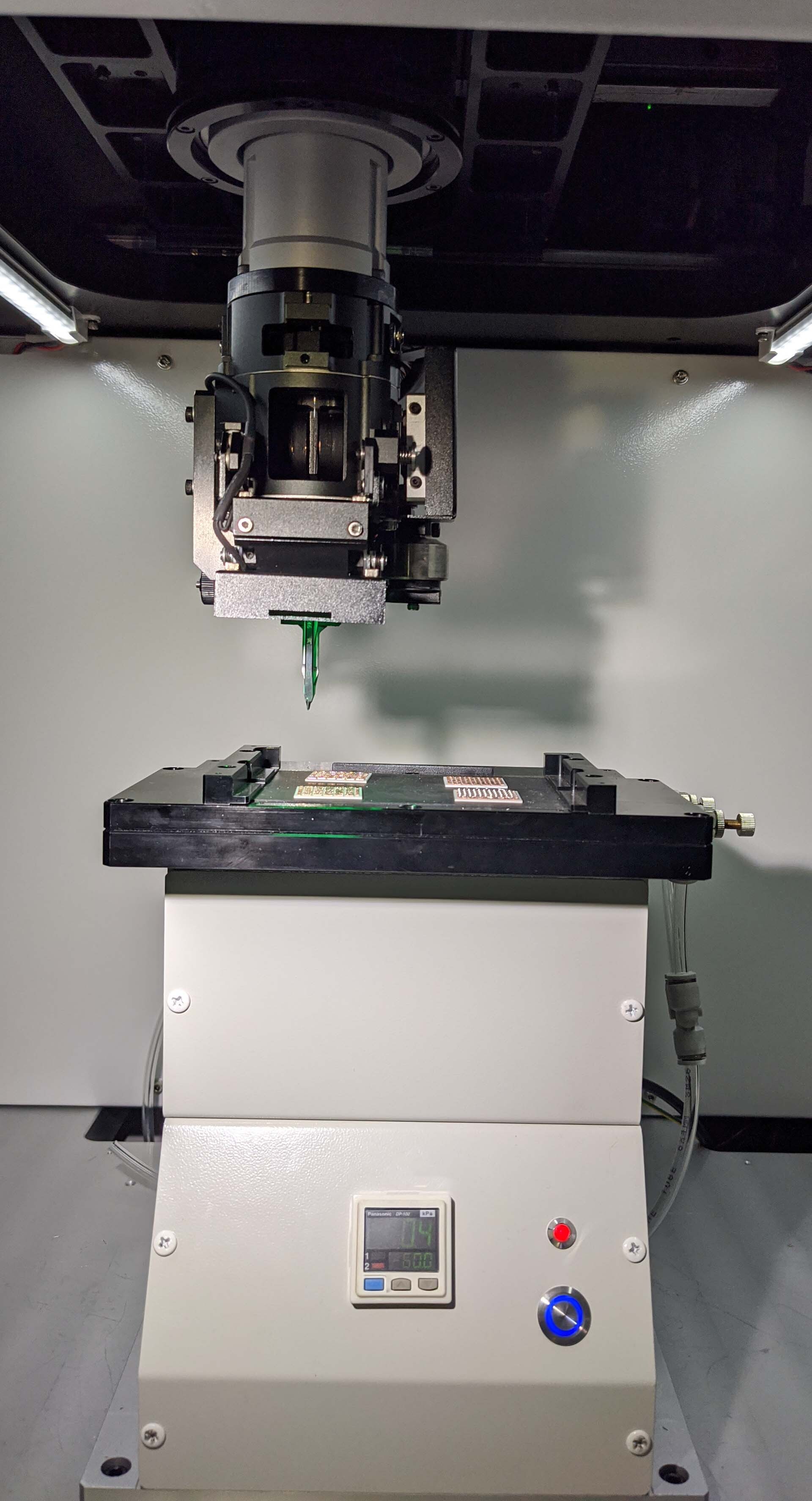

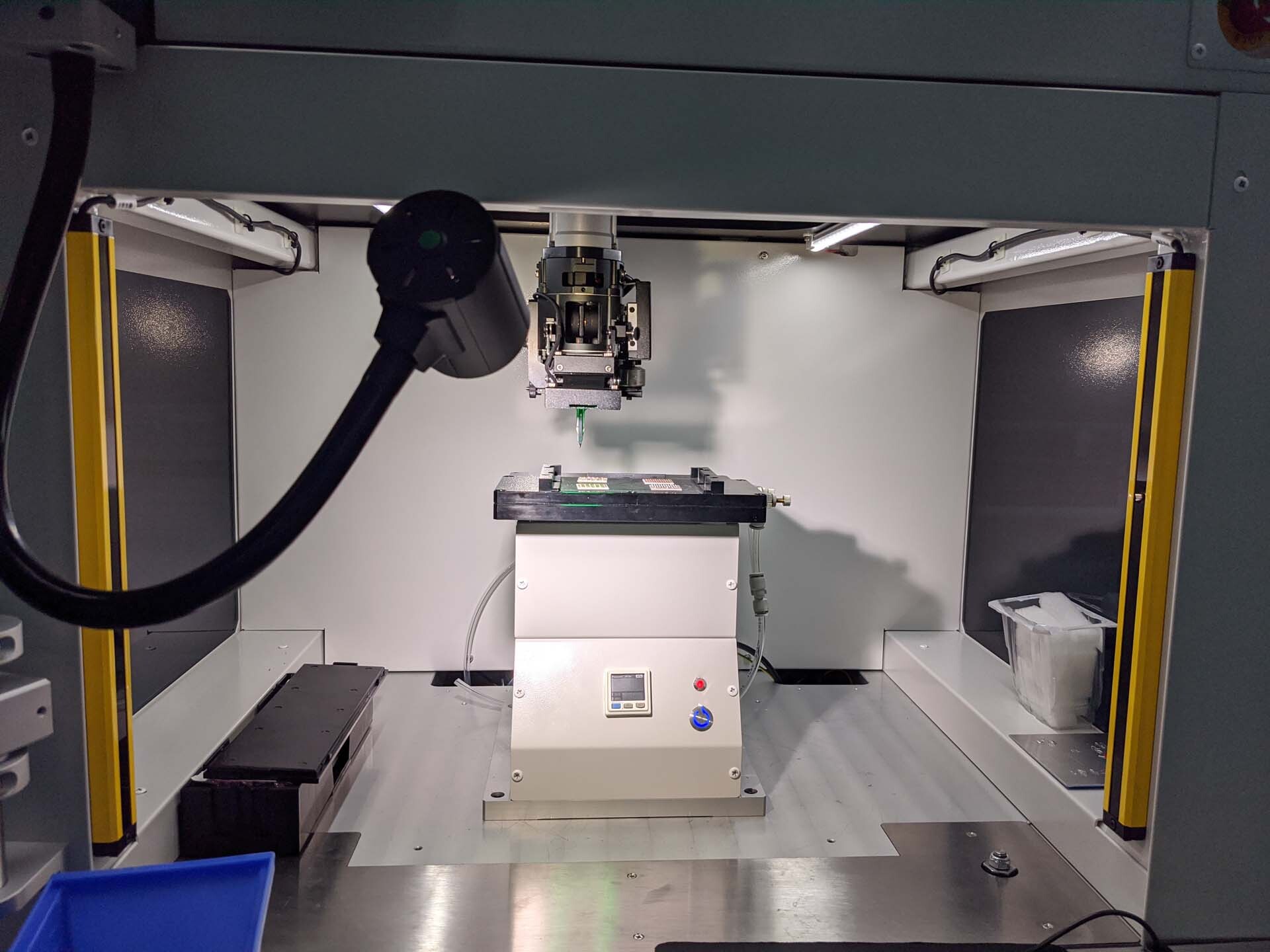

System

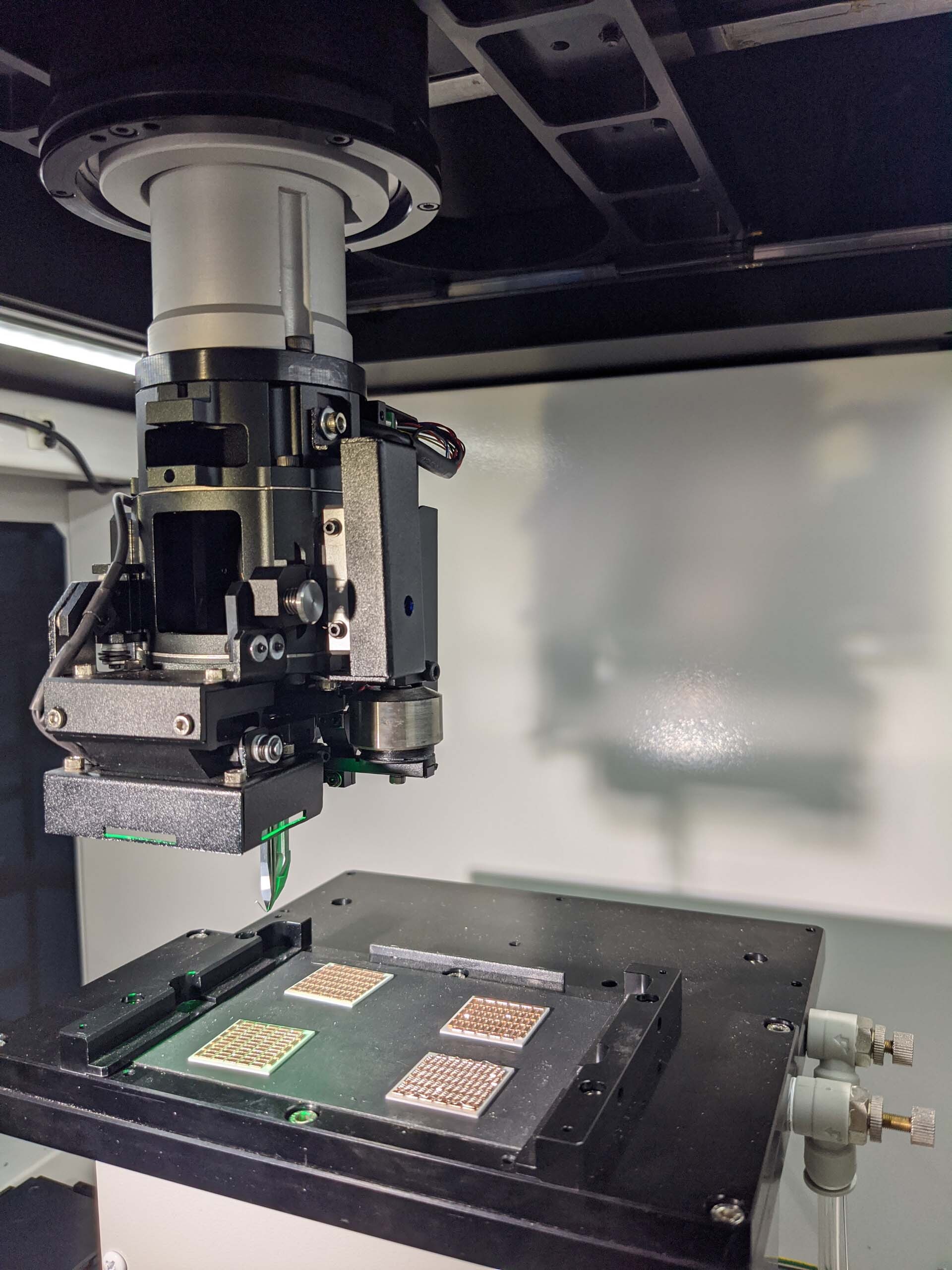

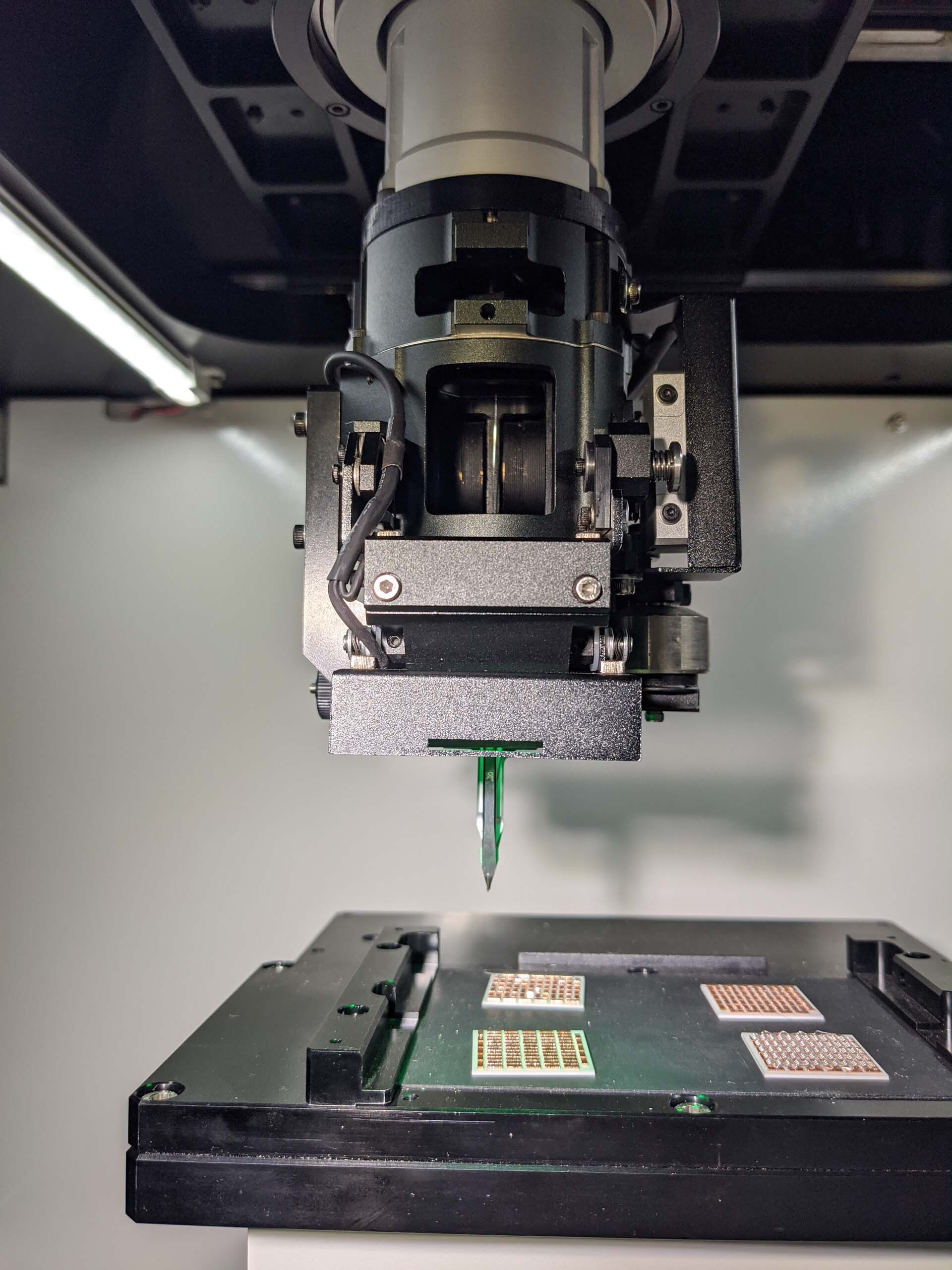

IGBT Module

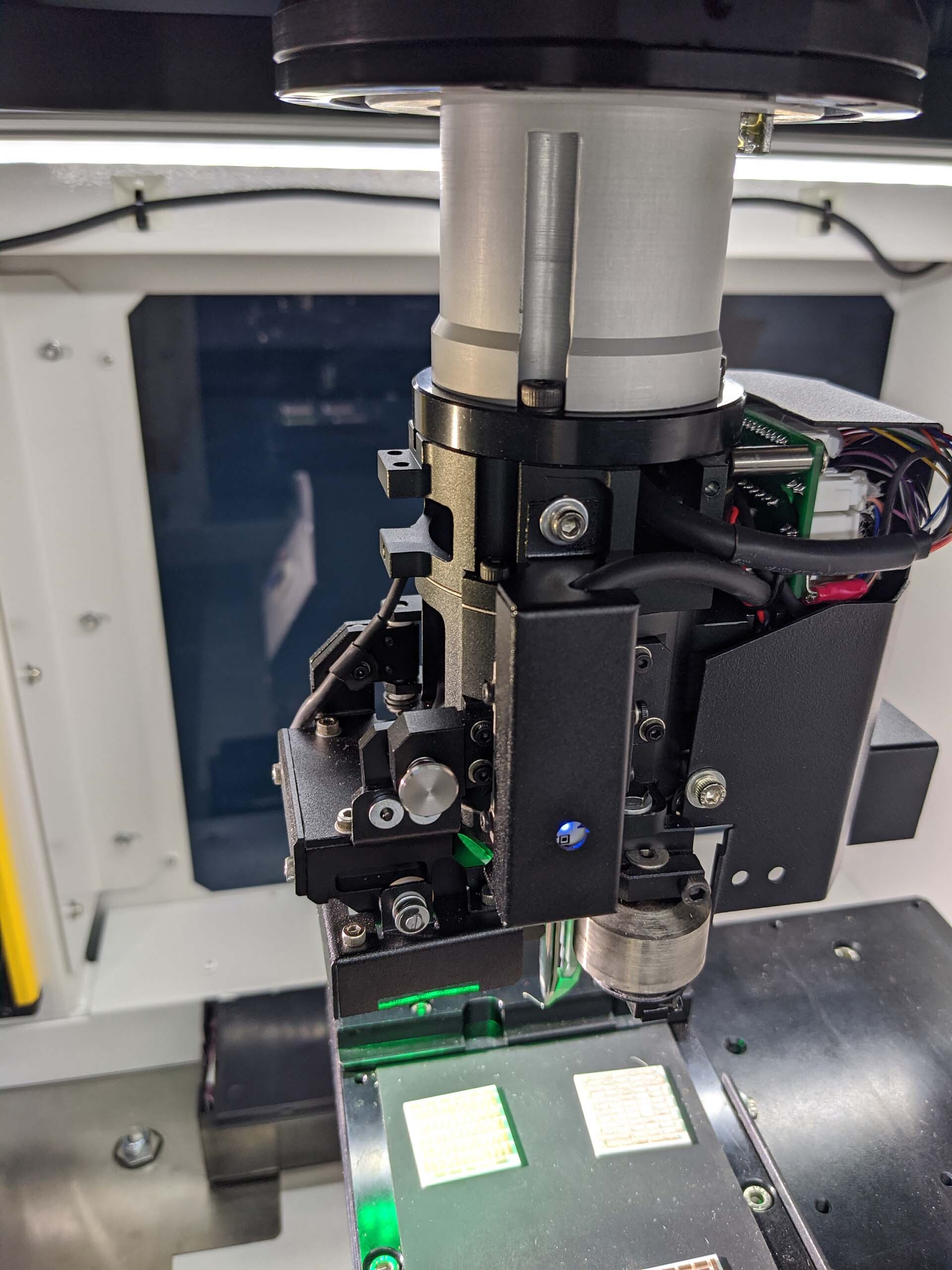

Bond effective area: 220 mm x 220 mm

Bond: 4-25 mil

AI Wire

AI Ribbon

Copper wire

Copper ribbon.

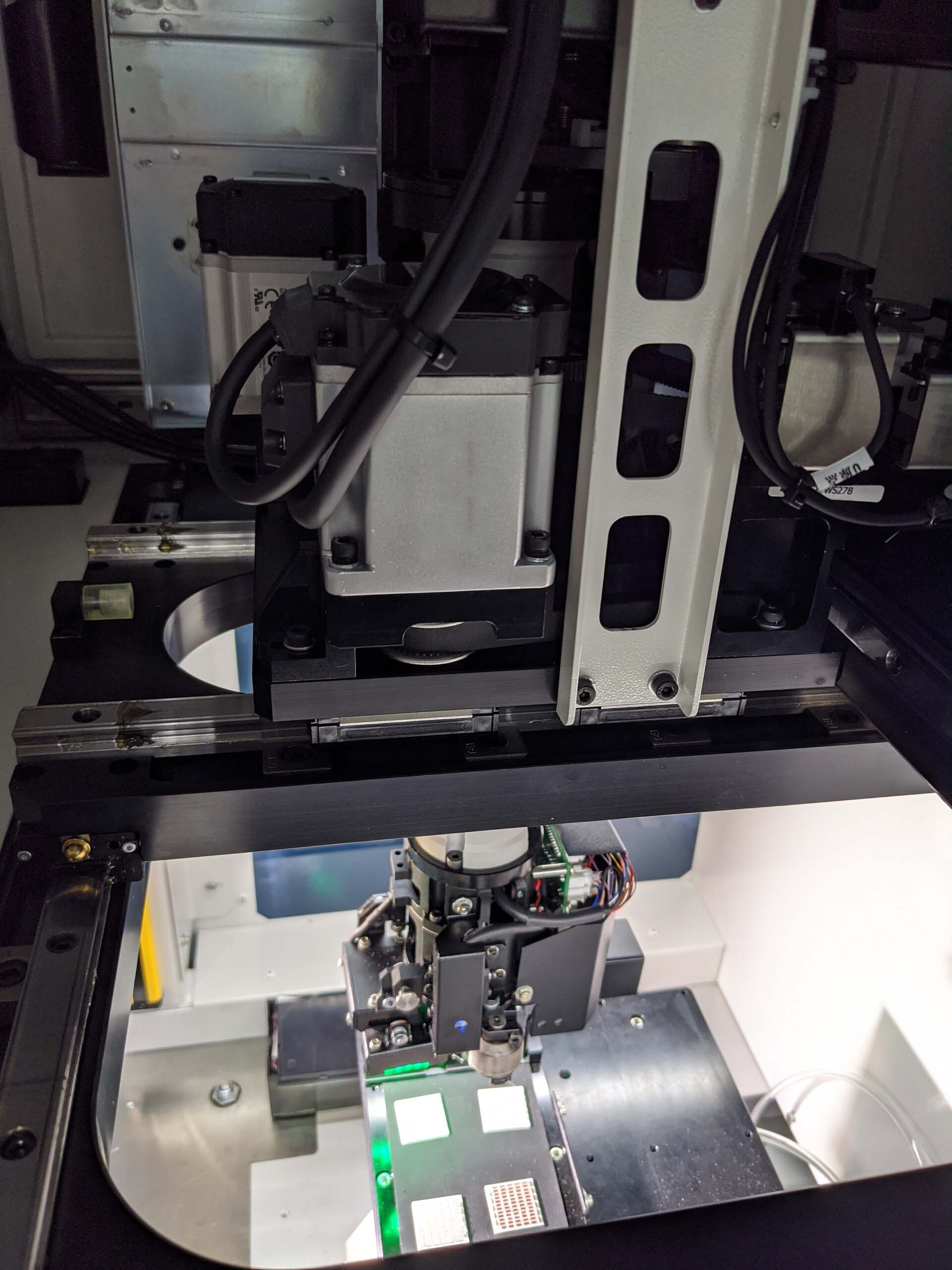

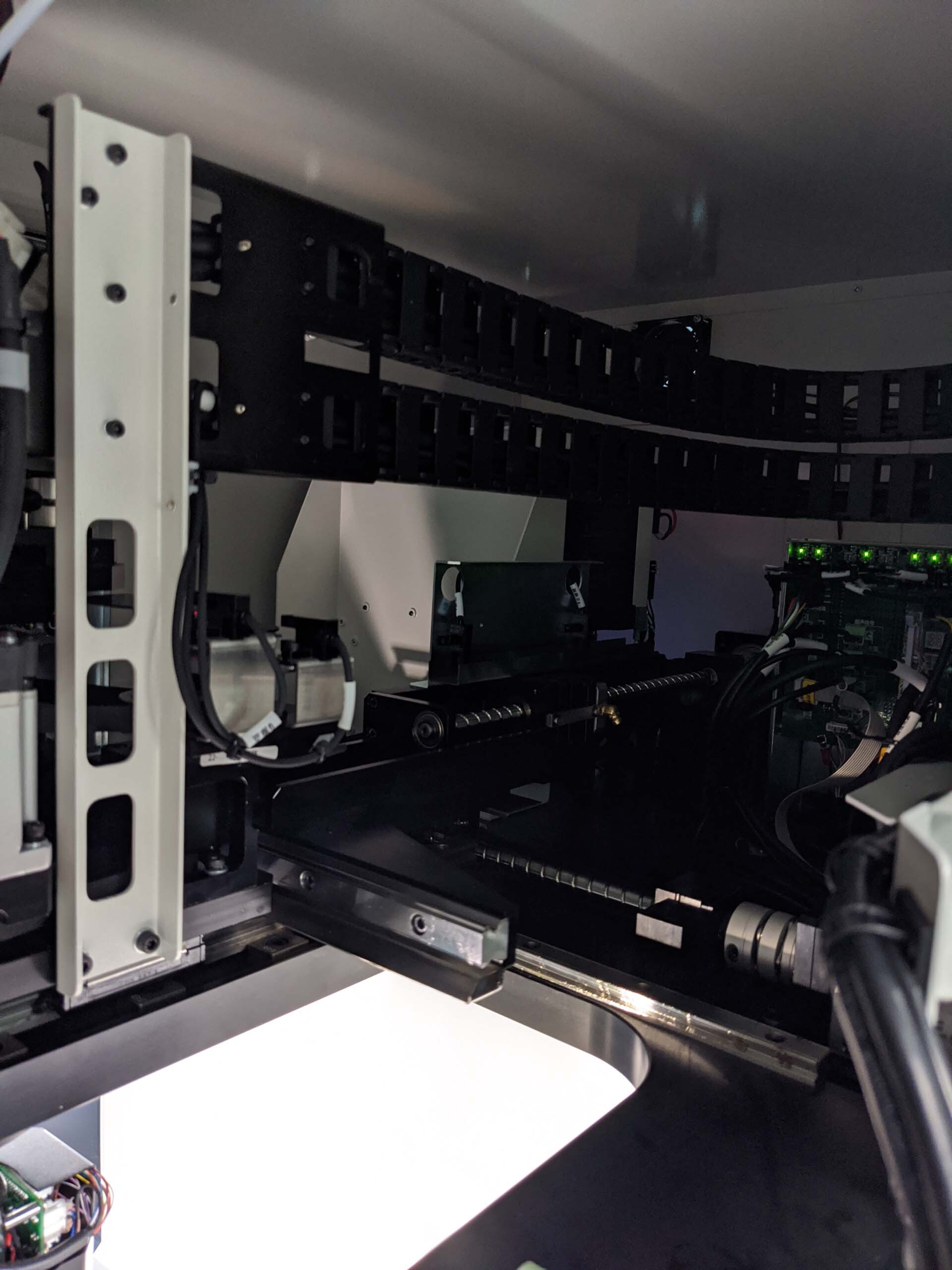

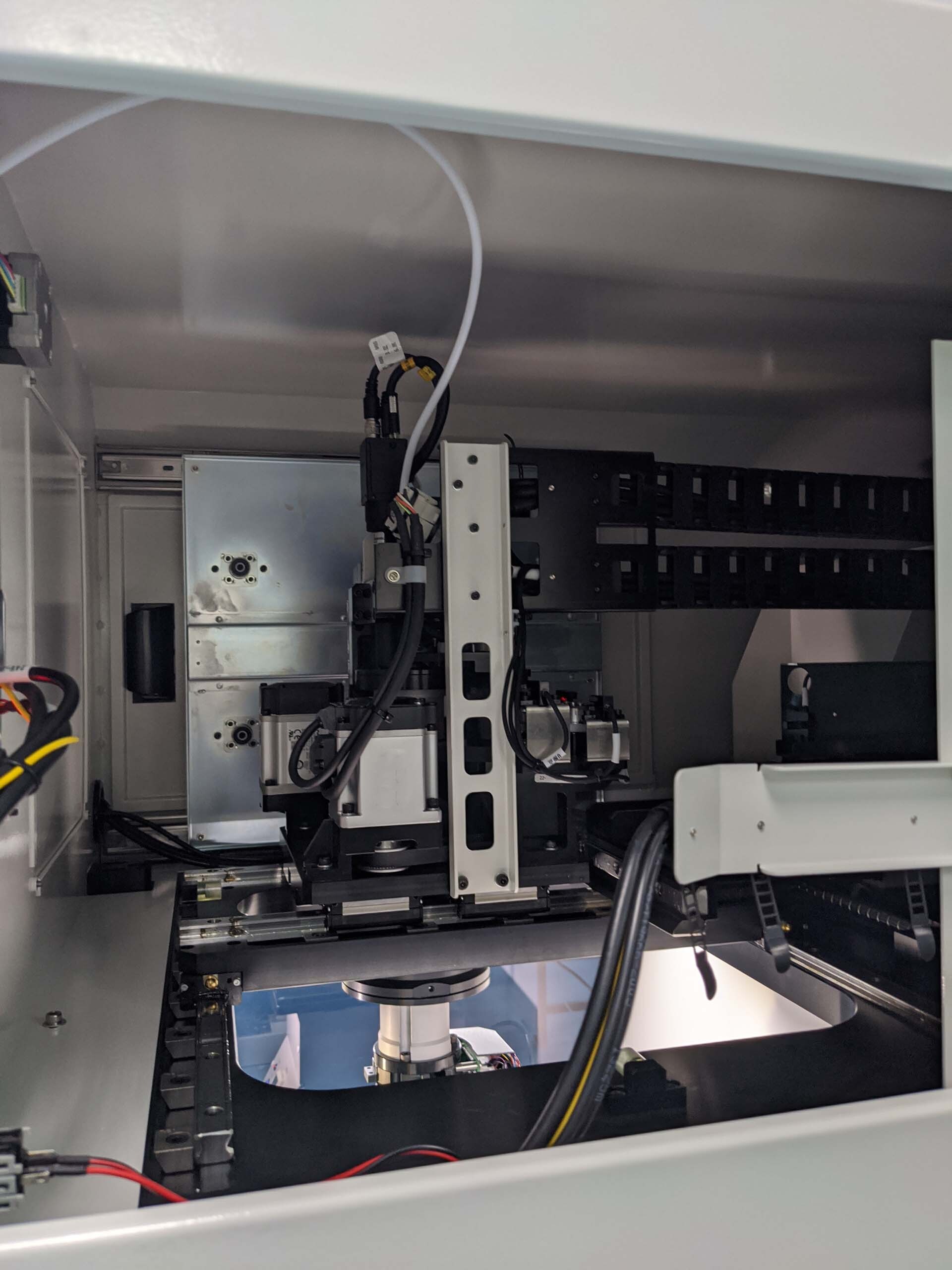

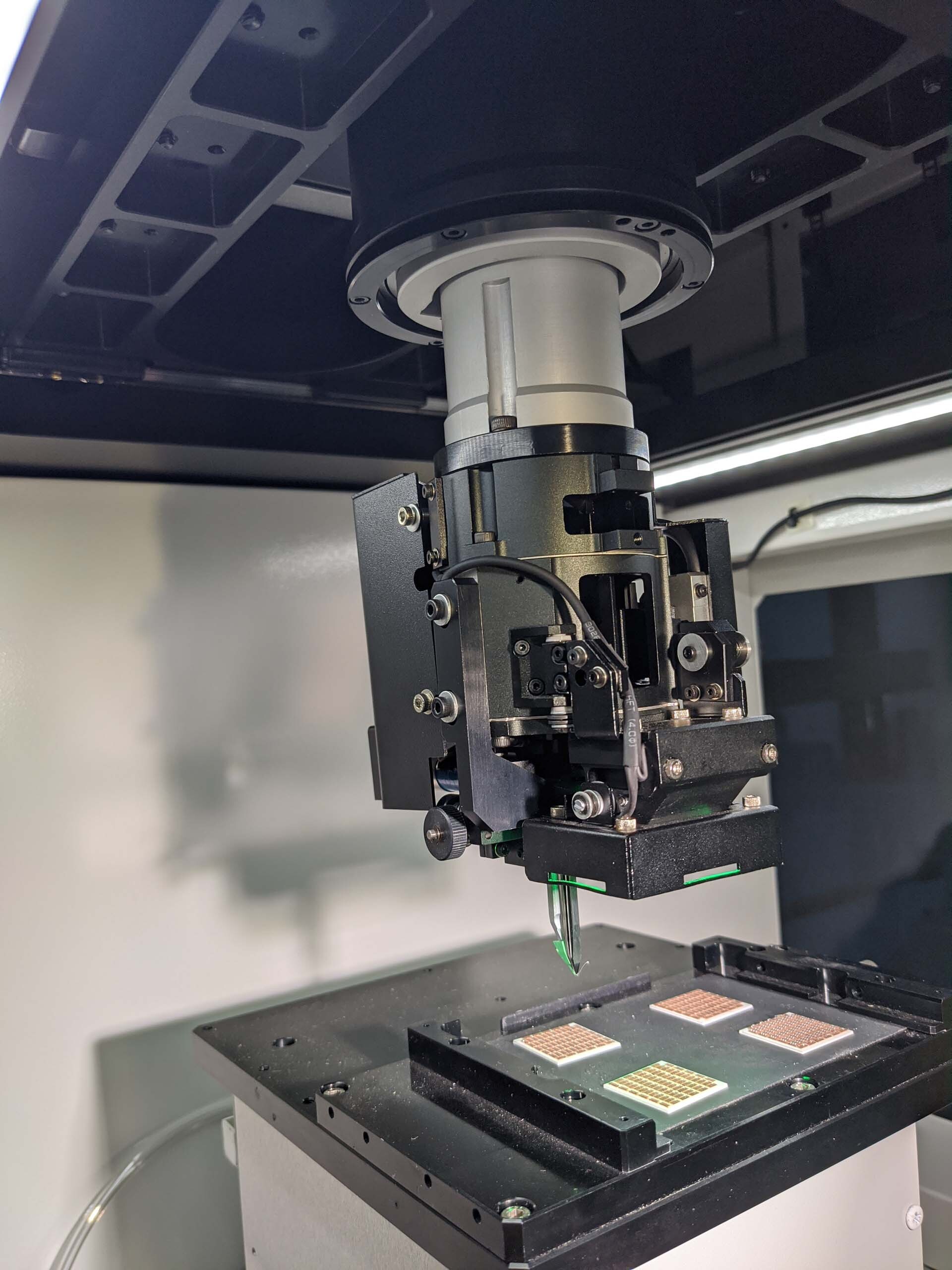

DAVOSEMI D-MAX is a wafer processing equipment designed to facilitate a wide array of wafer fabrication tasks. It is designed to handle various types of wafers including silicon and compound semiconductor, MEMS and optoelectronic wafers. The system comprises a stationary, heavy duty, die-bonding unit, a gantry-style robot, a series of freeze and freezeout chambers, and an advanced control unit. The die-bonding unit consists of an air-driven press with a controllable pressure range of 10 to 65 grams per square inch. The die-bonding unit is programmed to operate in two different modes; bonding and debonding. The bonding mode allows for the accurate and repeatable placement of wafers on the substrate, while the debonding mode allow for easy and fast removal of the wafer from the substrate. The gantry-style robot allows for precise, automated movement of the die-bonding unit. The robot has a maximum speed of 160mm/second, and a boost speed of 1,800mm/second. The robot arm can accommodate wafer sizes up to 25mm in diameter. D-MAX is equipped with several freeze and freezeout chambers. This allows for a variety of processes to be undertaken on the same wafer platform, such as ion implantation, diffusion, etching and lithography. The freeze and freezeout chambers are are temperature-controlled using an advanced P.I.D. temperature controller. DAVOSEMI D-MAX features an advanced control machine that allows for precise control of all stages of the fabrication process. This includes the programming and compliance of all the electronics and functions of the robot, the control of the air pressure, temperature control and compliance of the freeze and freezeout chambers, and the input and output. The control tool is capable of calculating the exact sequence of processes and provides flexible programming options. In summary, D-MAX is a highly advanced wafer processing asset that allows for accurate and repeatable wafer fabrication. It comprises a die-bonding unit, a gantry-style robot, a series of freeze and freezeout chambers and an advanced control model. This equipment is designed to handle various types of wafers including silicon and compound semiconductor, MEMS and optoelectronic wafers.

There are no reviews yet