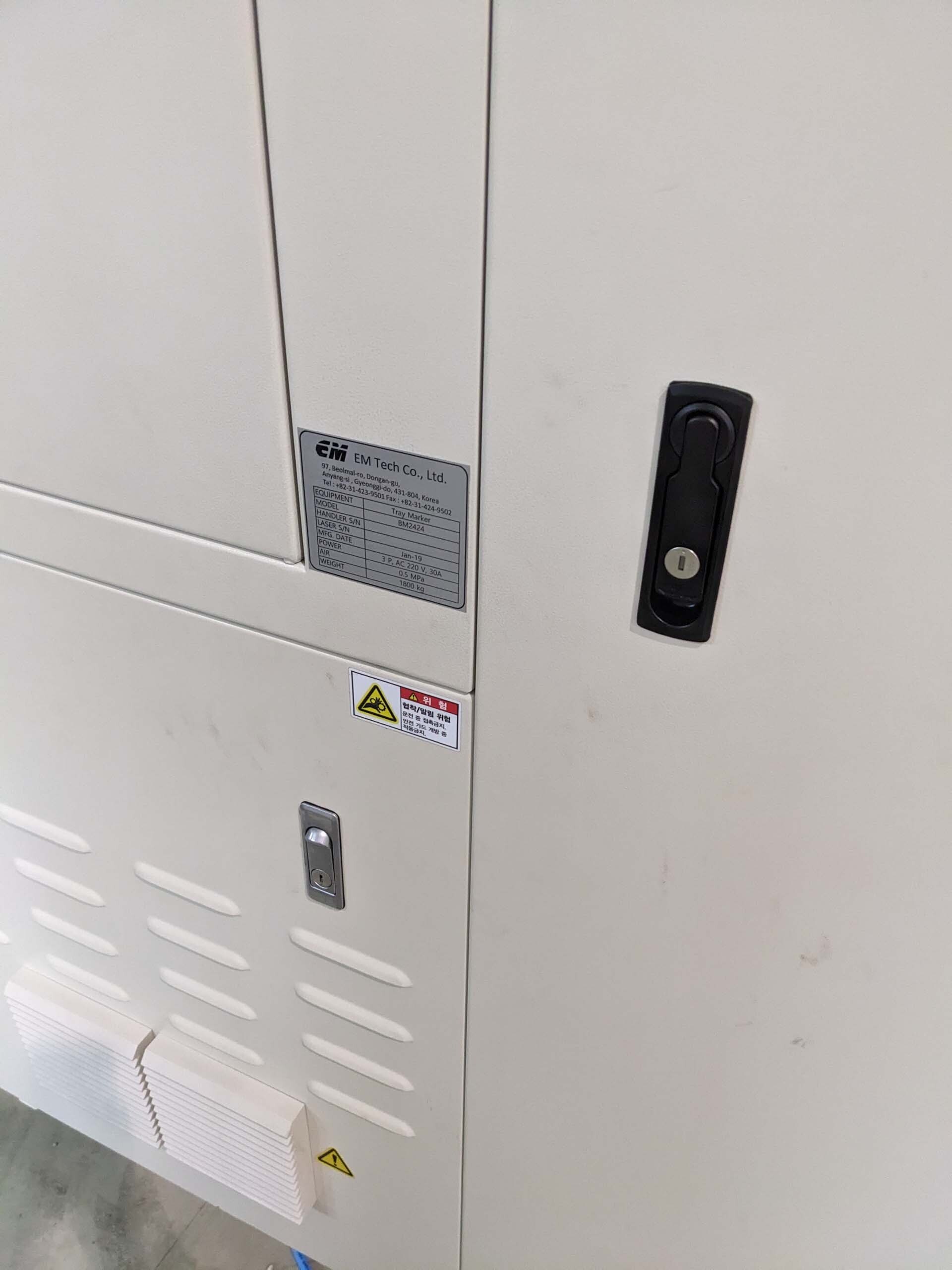

Used EM TECH BM2424 #293660908 for sale

URL successfully copied!

Tap to zoom

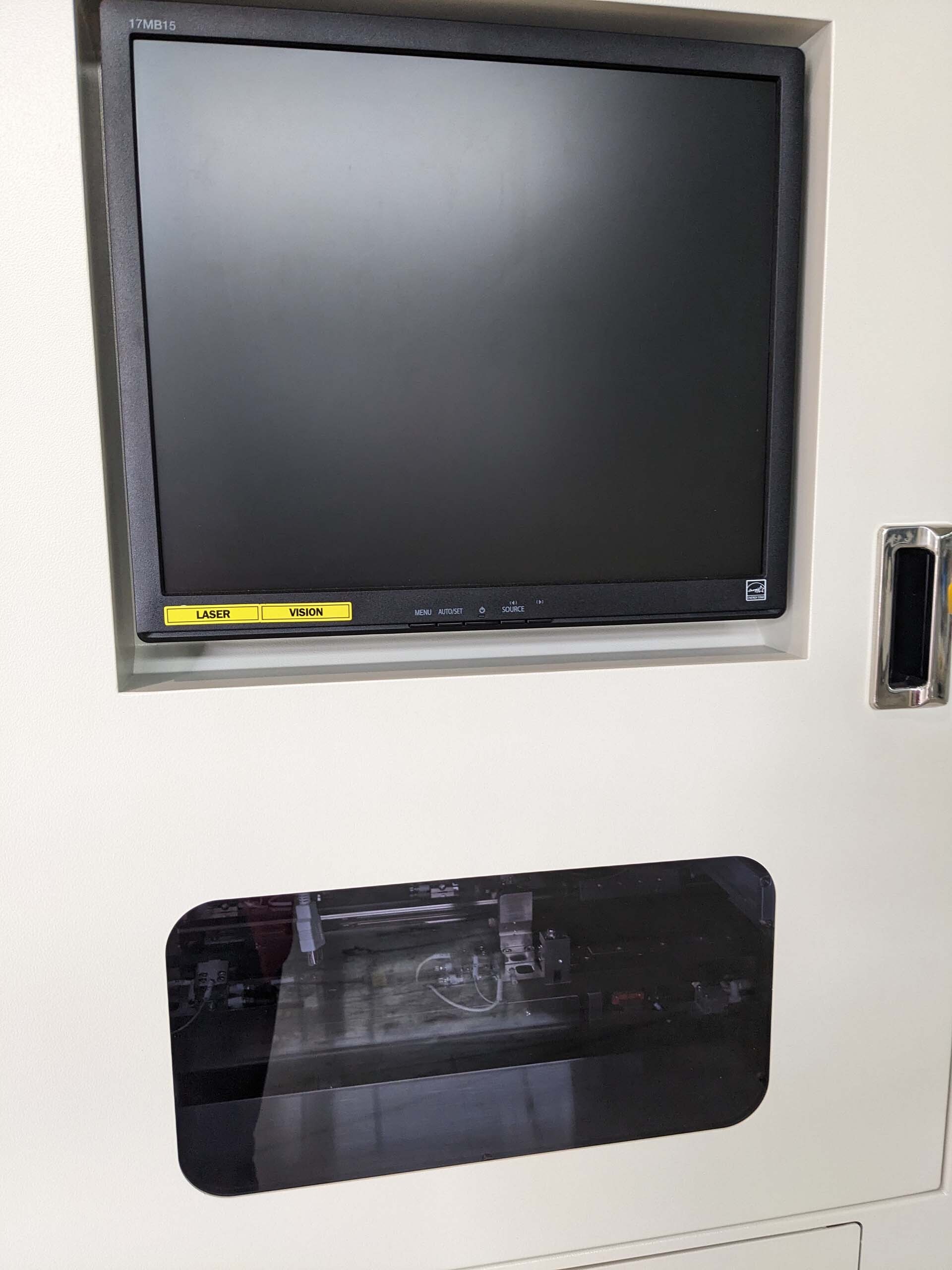

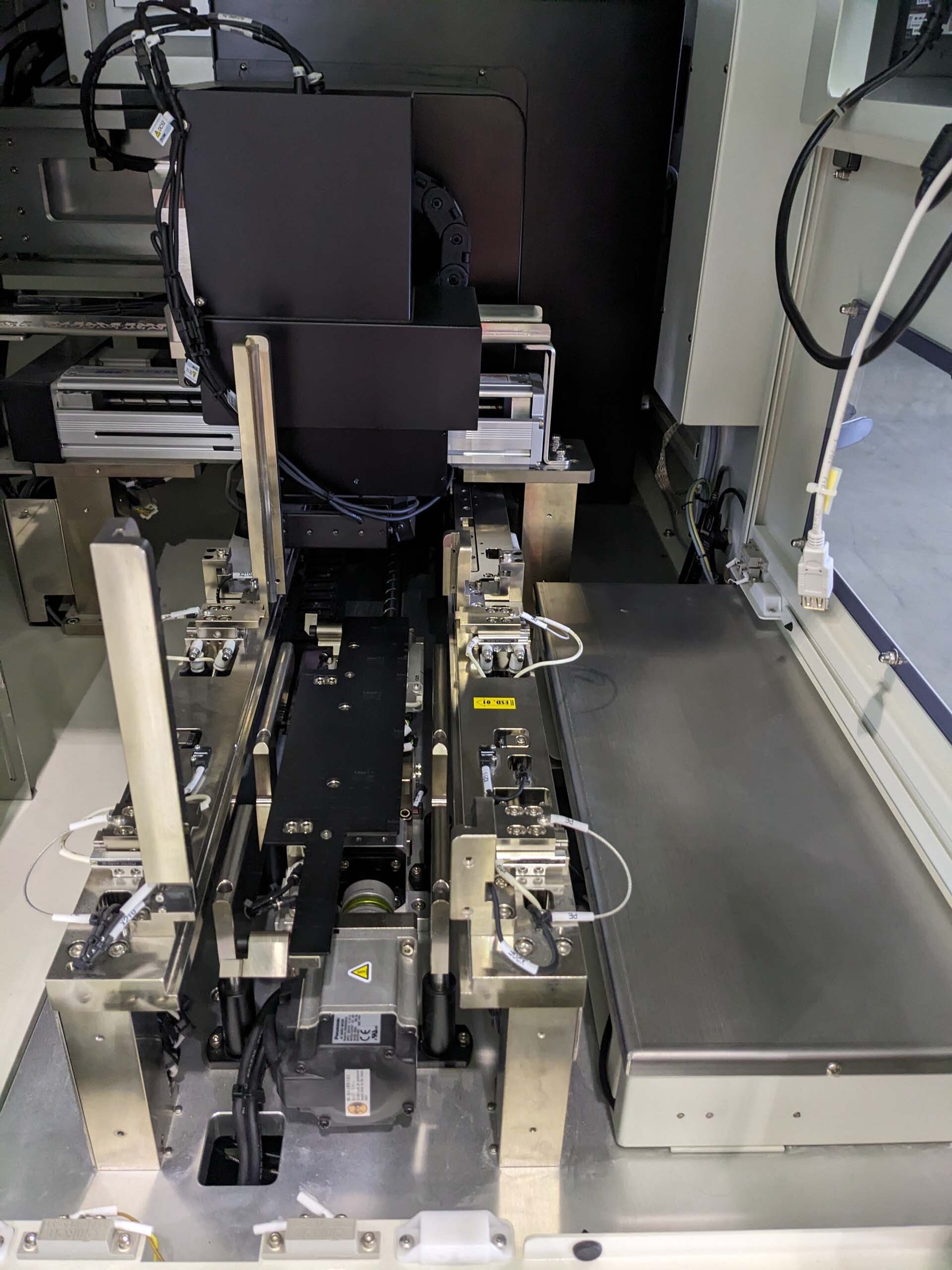

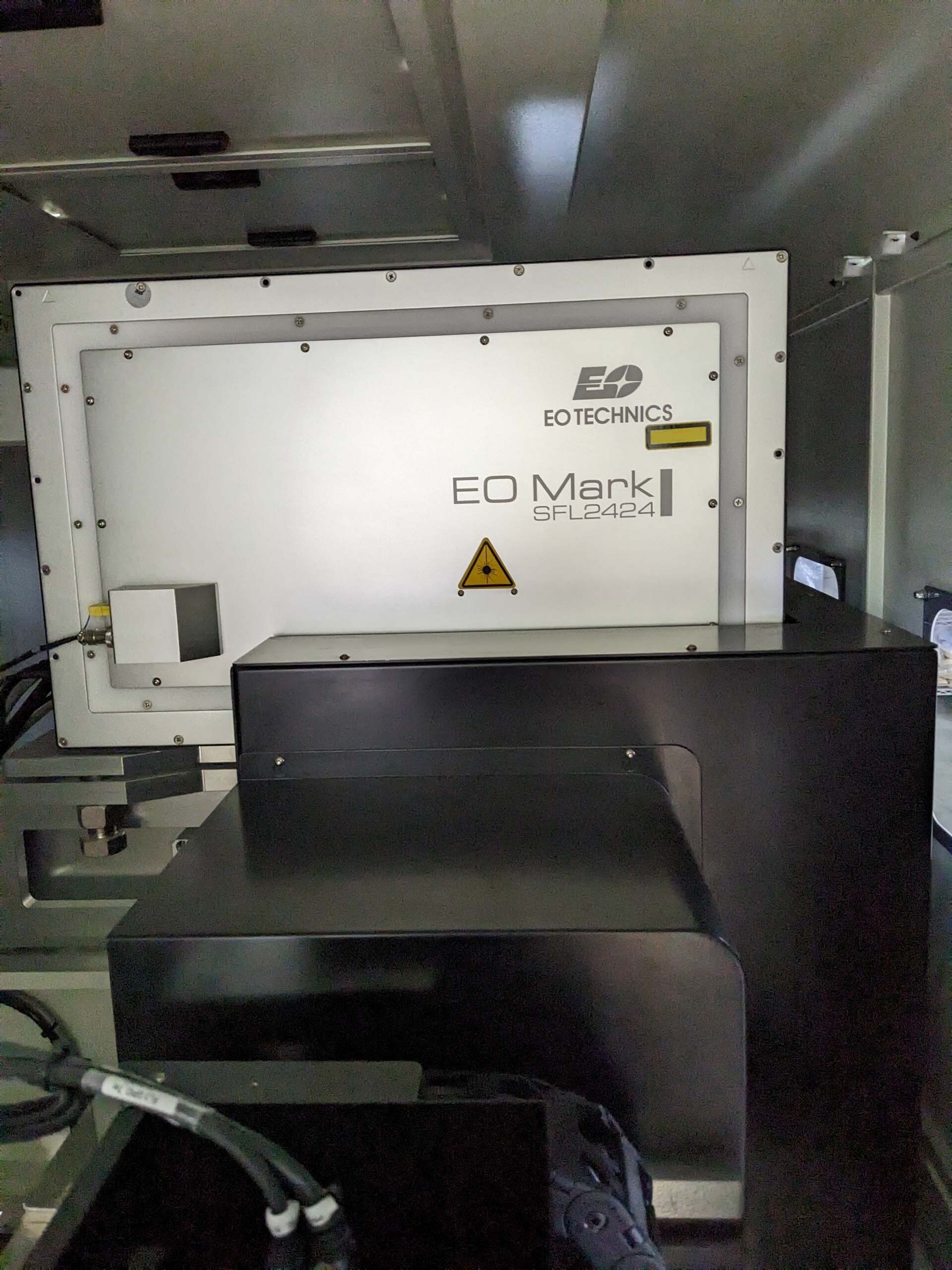

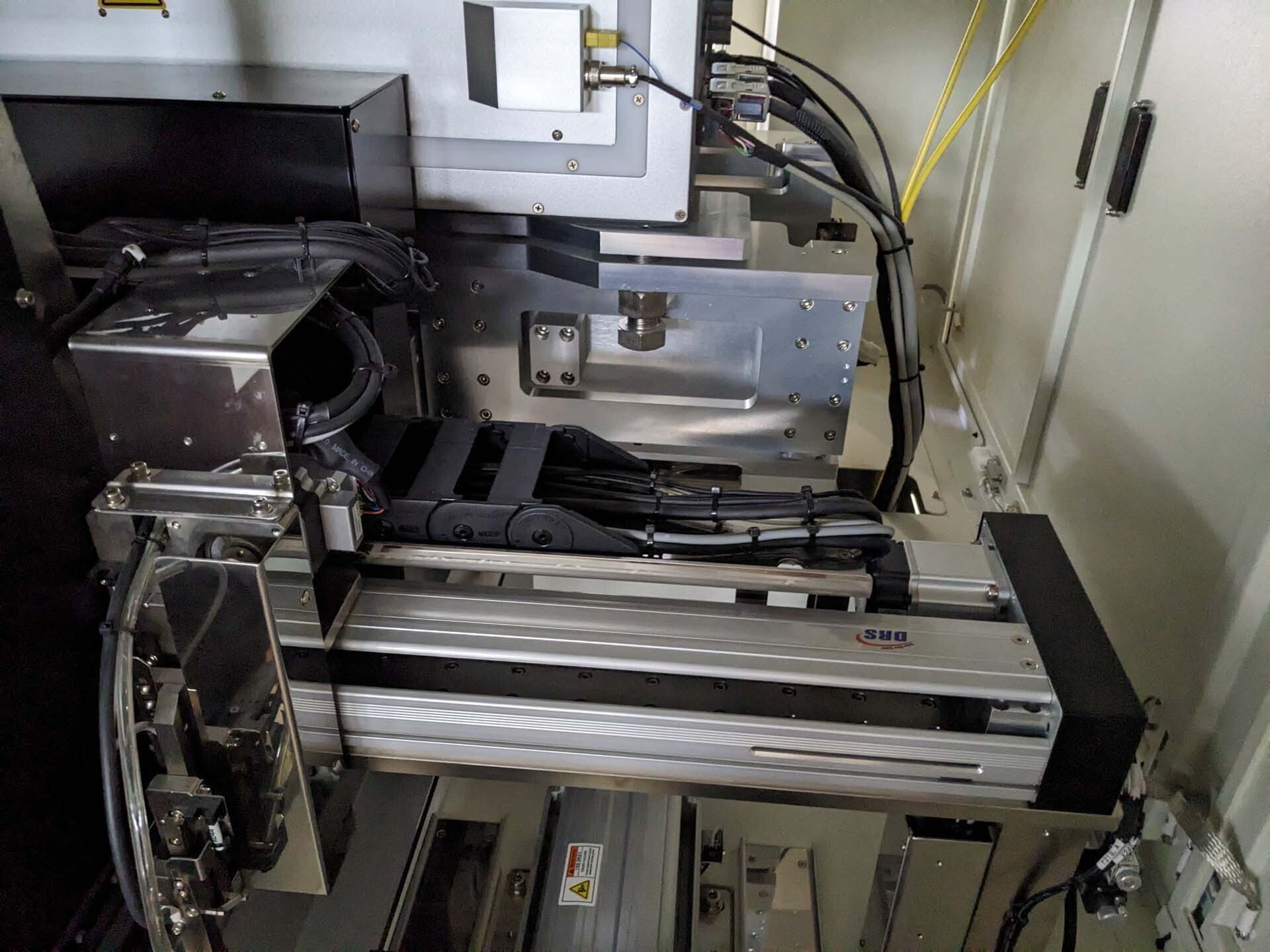

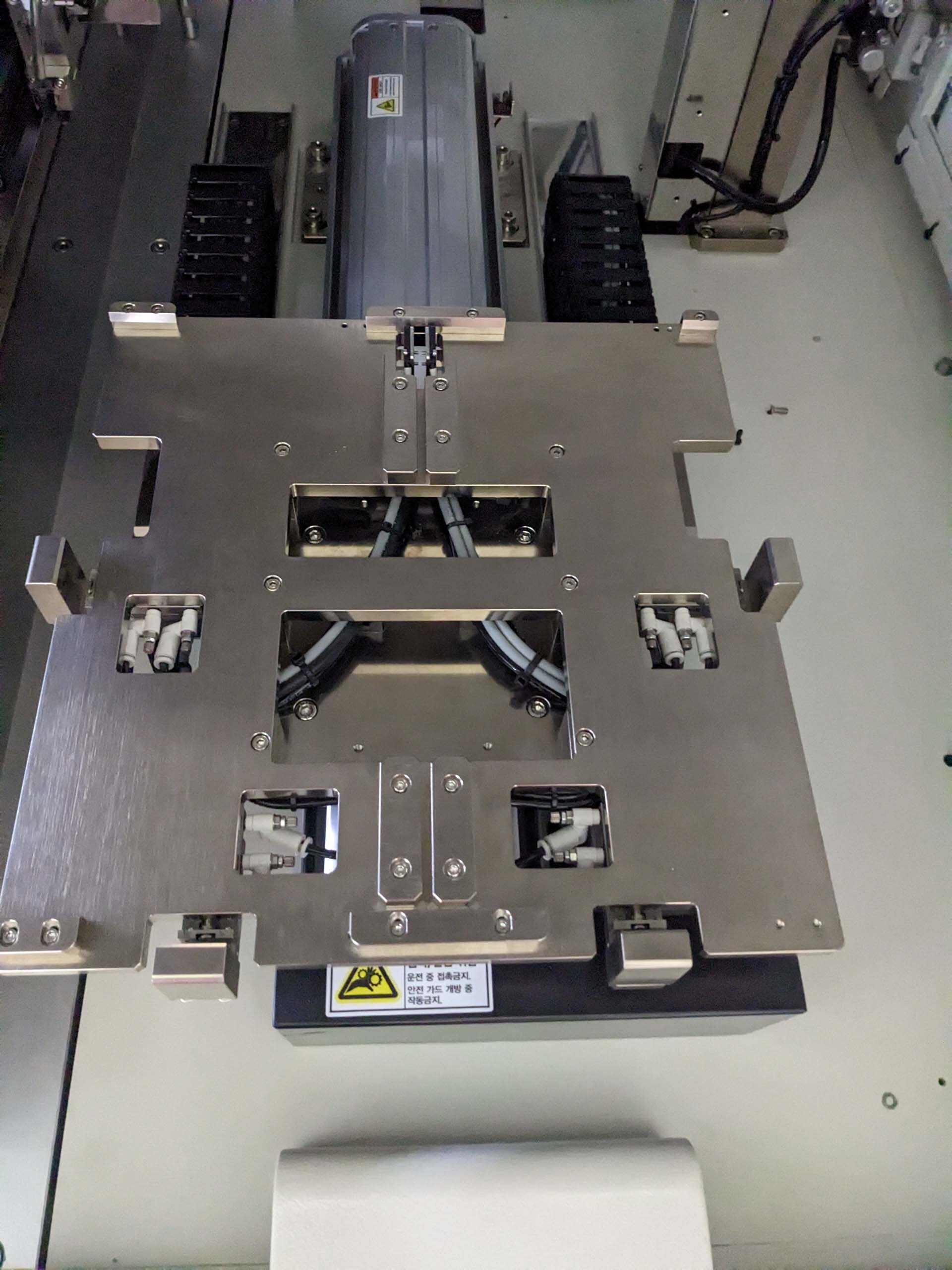

EM TECH BM2424 is a fully automated, multi-functional wafer processing equipment designed for use in a wide range of industries including semiconductor and microelectronics production. The system combines high process retention capability with repeatable, reliable and accurate process control, allowing users to process a variety of substrates with a high degree of repeatability. BM2424 features a 250mm x 250mm x 200mm process chamber that is designed to accommodate a wide variety of wafer sizes ranging from 3" to 8" in diameter and 0.8mm to 8mm in thickness. The unit includes a variety of process chambers, including an etch chamber, a polish chamber, a dry etch chamber, and a wet etch chamber. Each process chamber is designed to optimize wafer profile uniformity while facilitating cleaning, washout and preparation for the next process step. A high-performance 20nm quartz spinner is included as part of EM TECH BM2424 machine. This spinner has been designed to provide uniform distribution of the wafer-associated materials while avoiding any potential damage of the wafer edge by the rotational force. The spinner also ensures that any trapped gases contained inside the process chamber are removed within a certain period of time, thus preventing any potential contamination of the wafer surface. BM2424's thin film deposition process utilizes a low-pressure physical vapor deposition (PVD) technique, allowing users to deposit thin films of various materials onto their substrates. The PVD technique utilizes both thermal and electron assisted bombardment to physically vaporize the target material, which is then re-condensed onto the wafer surface. The thickness of the deposited layer can be accurately controlled depending on the growth rate of the target material. EM TECH BM2424's in-situ endpoint detection capabilities allow users to accurately ascertain the thickness or step height of the thin film as the deposition process is underway. This endpoint detection tool monitors the deposition rate and stops the deposition process when the desired film thickness or step height is reached. The endpoint parameters can be stored for later usage and are easily customizable for different applications. BM2424's wafer handling robot is highly efficient and designed for a minimum of 100 wafers per cleaning and process cycle. The robot is also capable of handling a wide range of different types of wafers, from soft and delicate to hard and robust. The wafer handling robot allows the operator to select the number of wafers to be processed and the specific process parameters that must be applied. EM TECH BM2424 includes a variety of specialized process chamber accessories. An integrated stainless steel washout station allows users to quickly clean the process chamber before each new process cycle, ensuring the highest level of cleanliness. A temperature-controlled transfer arm enables users to quickly and accurately transfer important data from the control asset to the process chamber, reducing the risk of any data loss or errors. BM2424 is a comprehensive and reliable wafer processing model that offers users a combination of accuracy, repeatability, and high throughput in a variety of industries. The equipment's intuitive user interface, automatic endpoint detection capabilities, and durable construction make it an ideal choice for semiconductor and microelectronics production requirements.

There are no reviews yet