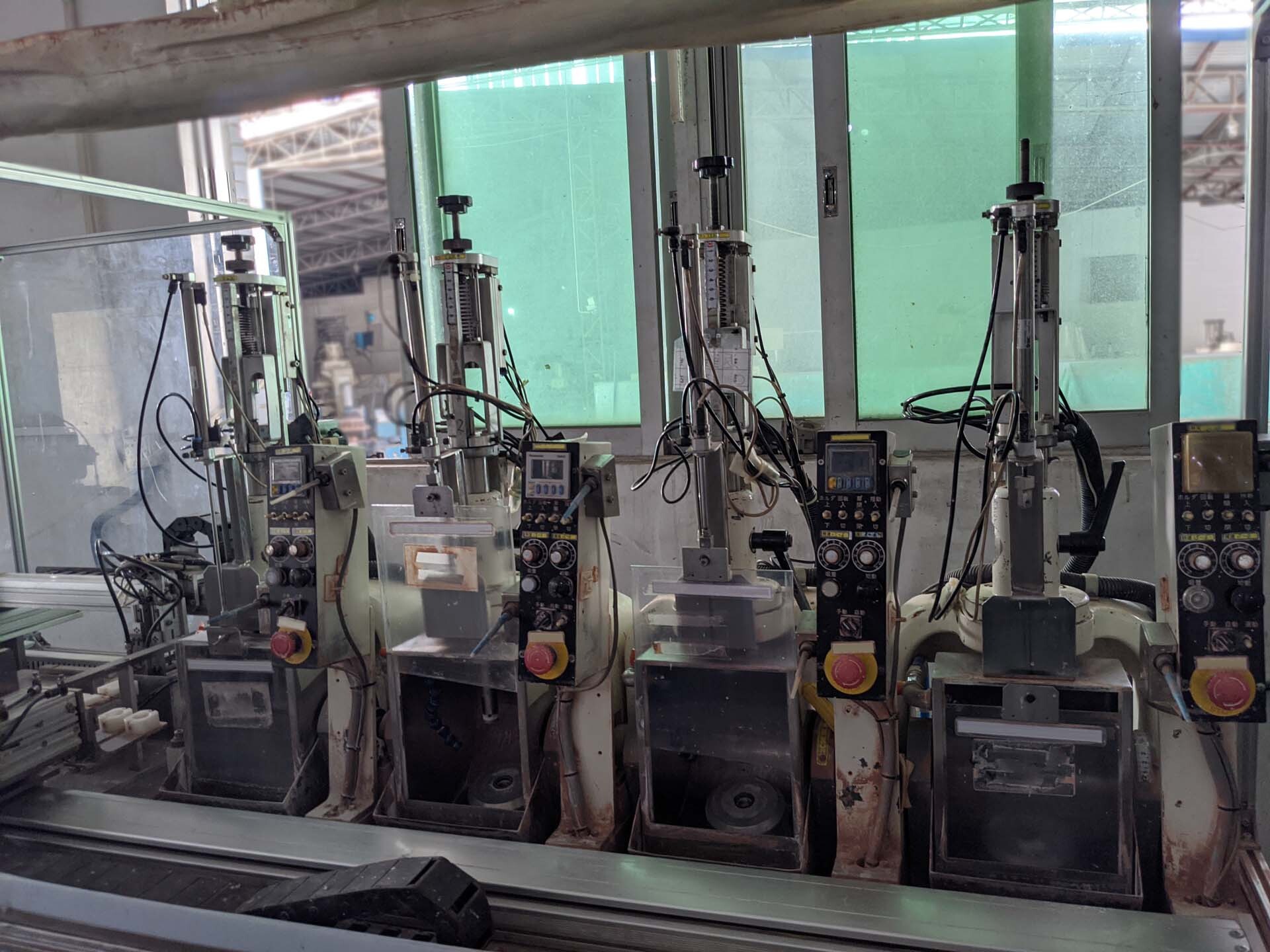

Used HARUCHIKA HPS-50-4P #293663511 for sale

URL successfully copied!

Tap to zoom

HARUCHIKA HPS-50-4P is a highly advanced wafer processing equipment designed with cutting-edge technology to meet the needs of modern research and development laboratories. The system is renowned for its versatility, with the ability to support various substrates from silicon wafers to photomasks, and its ability to handle everything from single to four-up wafer processing. This unit features a powerful 4-channel photo-mask circuit board, enabling it to support up to four 4-inch or 6-inch wafers simultaneously. Additionally, the auto-focus camera unit allows for precise focusing of each wafer's surface, reducing the chances of distortion or other issues. The pool of distributed lenses available with the machine is capable of magnifying images up to 800x, allowing researchers to take detailed images of wafers. The tool also comes with integrated thermal process controller which can facilitate the monitoring of wafer surface temperature during etching or development. The temperature control process is further enhanced with the addition of HARUCHIKA FHT-units, which help ensure the uniformity of the temperature throughout the wafer and ensure that the whole process is operating in the correct environment. HPS-50-4P also includes a "hot pressure cutting" asset. This model was created to accurately cut and edge wafers, with the ability to handle wafers up to 450.00 mm in diameter. The tool also utilizes a special thermal spray nozzle, which allows for the precise application of tightly focused particles onto the wafers' edges. This nozzle is needed for high accuracy cutting of the wafers boundary-lines and creates less chipping or bundling of the wafer than with other systems. HARUCHIKA HPS-50-4P also offers a full suite of software tools to track the progress of each wafer and monitor its production. This includes manual process control tools, designed to facilitate precise measurement and statistical process control data, and debugging tools to troubleshoot any process issues. Additionally, the equipment also supports data import and mapping as well as link management functions. In conclusion, HPS-50-4P is a highly advanced and versatile system for processing wafers. This unit simplifies and accelerates the wafer fabrication process while also allowing for accurate temperature control and precise cutting of even the smallest edges. With its full suite of software tools, it is suitable for any research and development environment.

There are no reviews yet