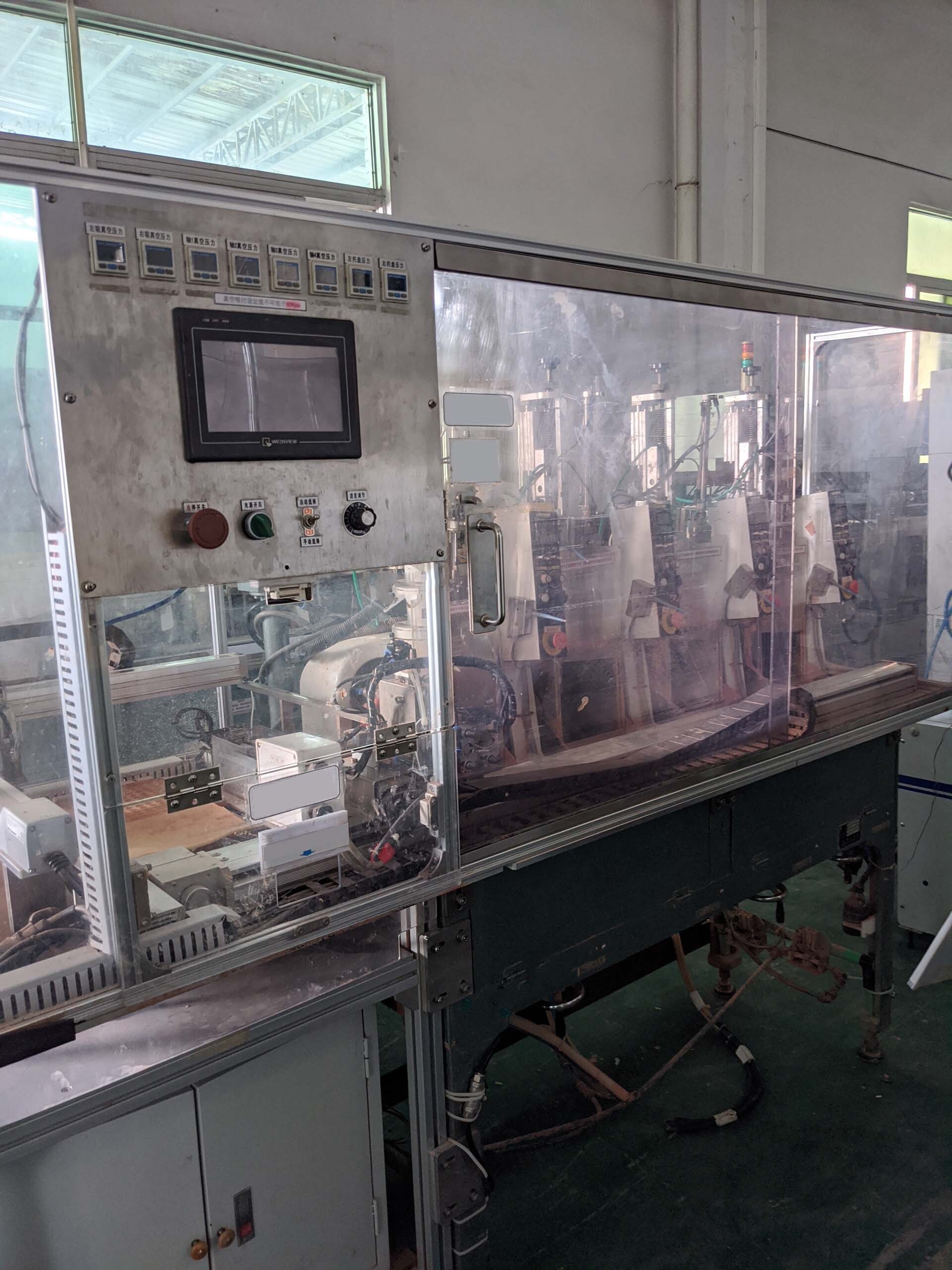

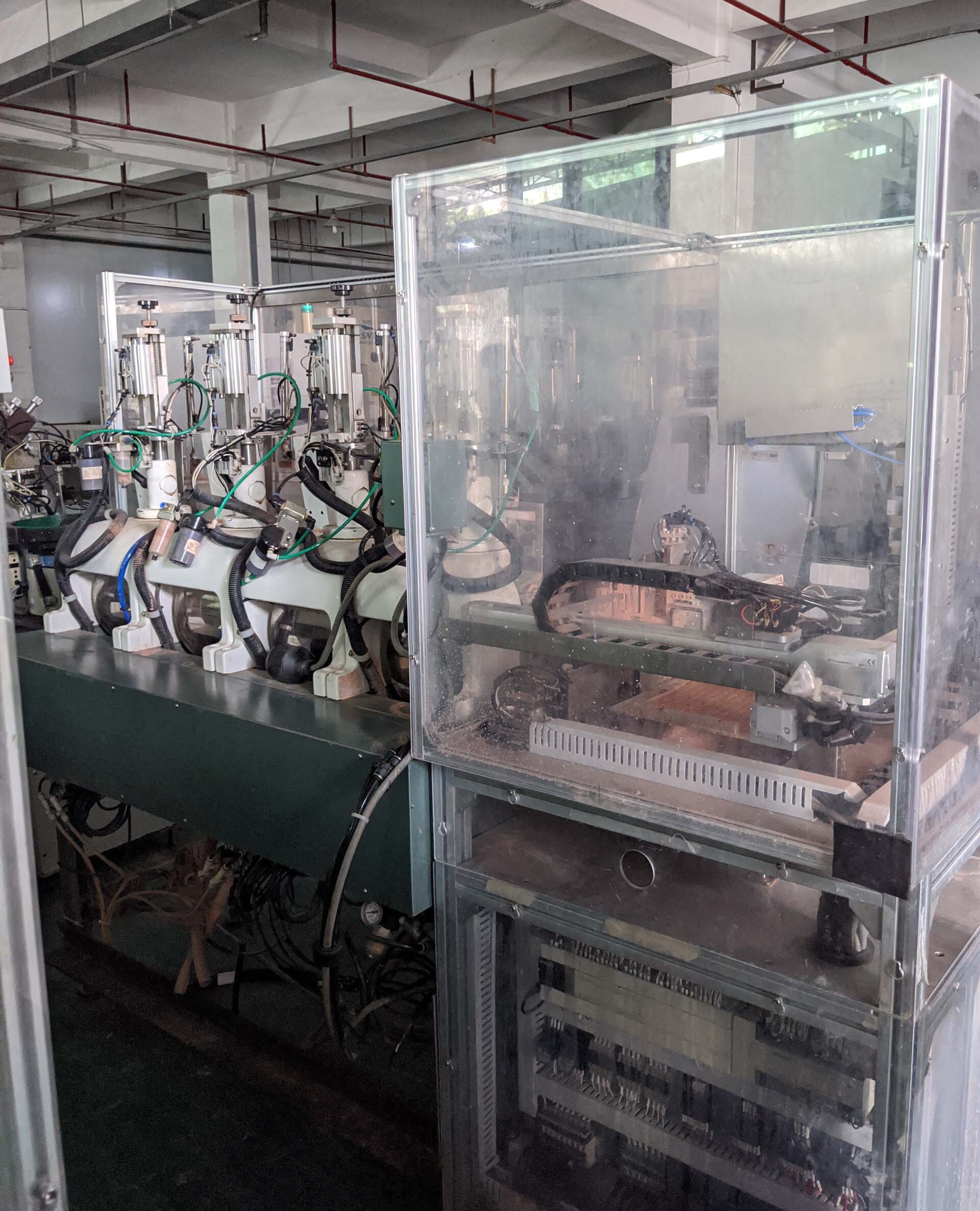

Used HARUCHIKA HPS-50-4P #293663526 for sale

URL successfully copied!

Tap to zoom

HARUCHIKA HPS-50-4P is a powerful, fully automated wafer processing equipment that enables semi-automated and manual microfabrication. This system is capable of carrying out a variety of high-precision processes in quick succession. HPS-50-4P has four primary and four secondary wafer processing stages and is designed to handle a wide array of processing needs. For example, it can be used for thin-film deposition, resist spin coating, photolithography, wet etching, ion milling, wafer bonding, and moulding. HARUCHIKA HPS-50-4P utilizes a linear motor-driven unit for accurate and precise movement of the wafers. This allows efficient and reliable operation of the machine for all of the processes. In addition, the tool provides advanced control over the position, speed, and acceleration of the wafers. This ensures maximum control over the processes. HPS-50-4P also features an integrated vision asset. This model makes it easier to ensure process accuracy and reliability across a wide range of applications. The vision equipment also enables automated wafer alignment and edge detection capabilities. The system comes with a range of other features designed to enable optimal wafer fabrication. These include an auto-shutdown feature to protect against mechanical stress, a monitor unit to measure the live performance of the machine, and a built-in database to store processes and data. Overall, HARUCHIKA HPS-50-4P is a powerful and versatile wafer processing tool that is capable of quickly and reliably carrying out a wide array of operations. The integrated vision asset makes it easy to ensure accuracy and reliability, and the wide range of features helps maintain optimal performance. All this adds up to a model that is perfect for users that require high-precision wafer processing capabilities.

There are no reviews yet