Used KINETICS MegaFlow II #9226730 for sale

URL successfully copied!

Tap to zoom

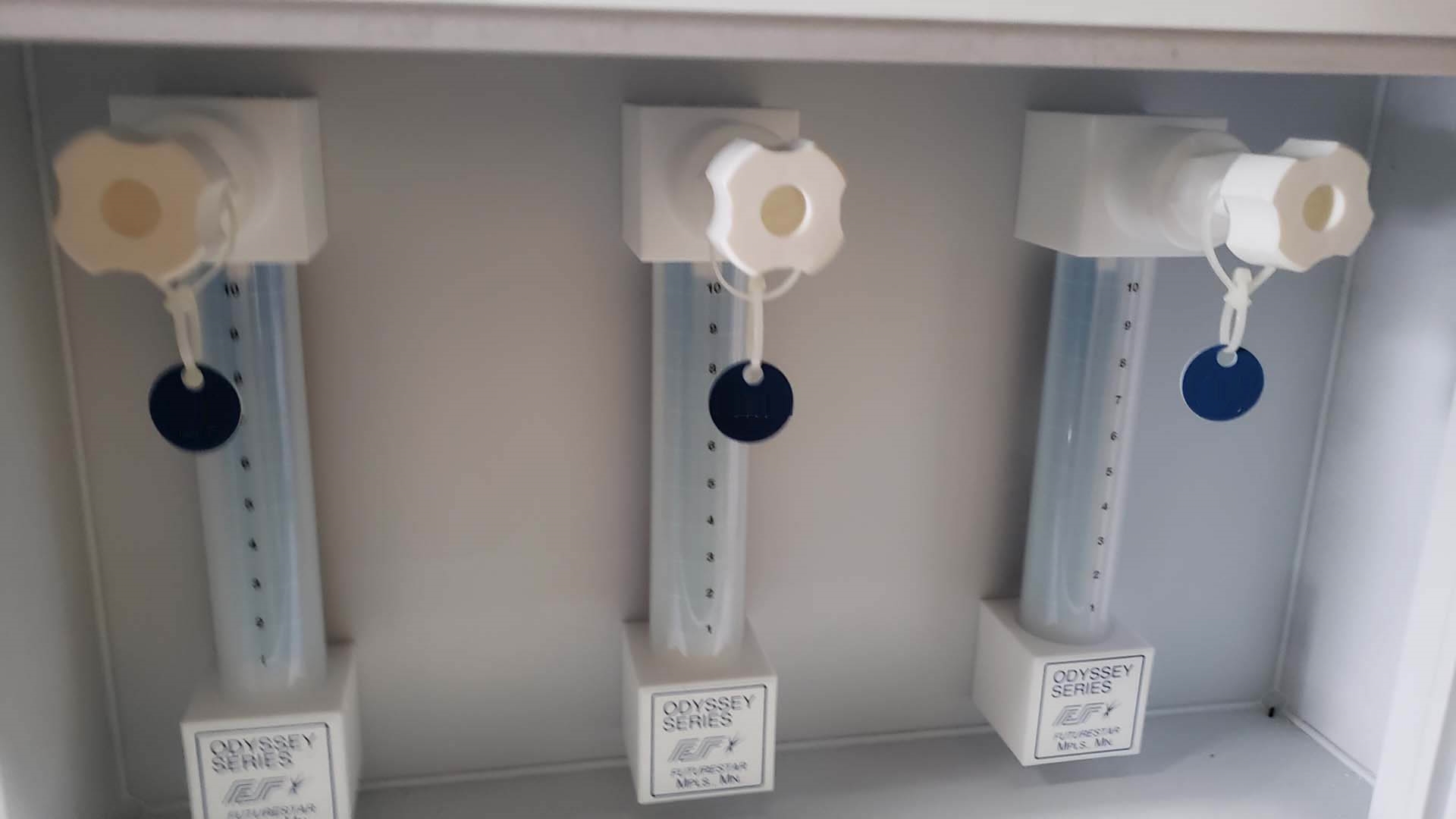

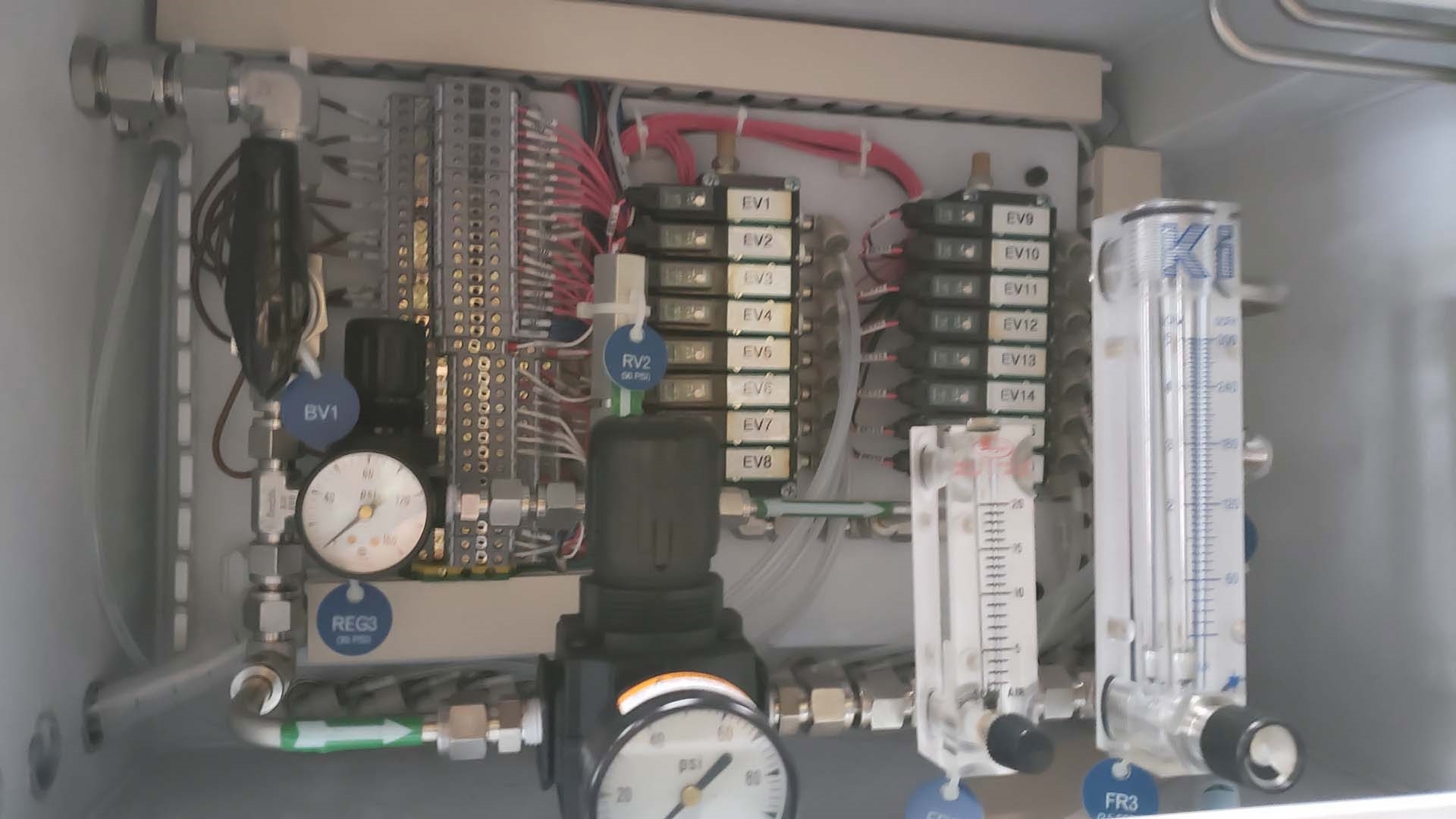

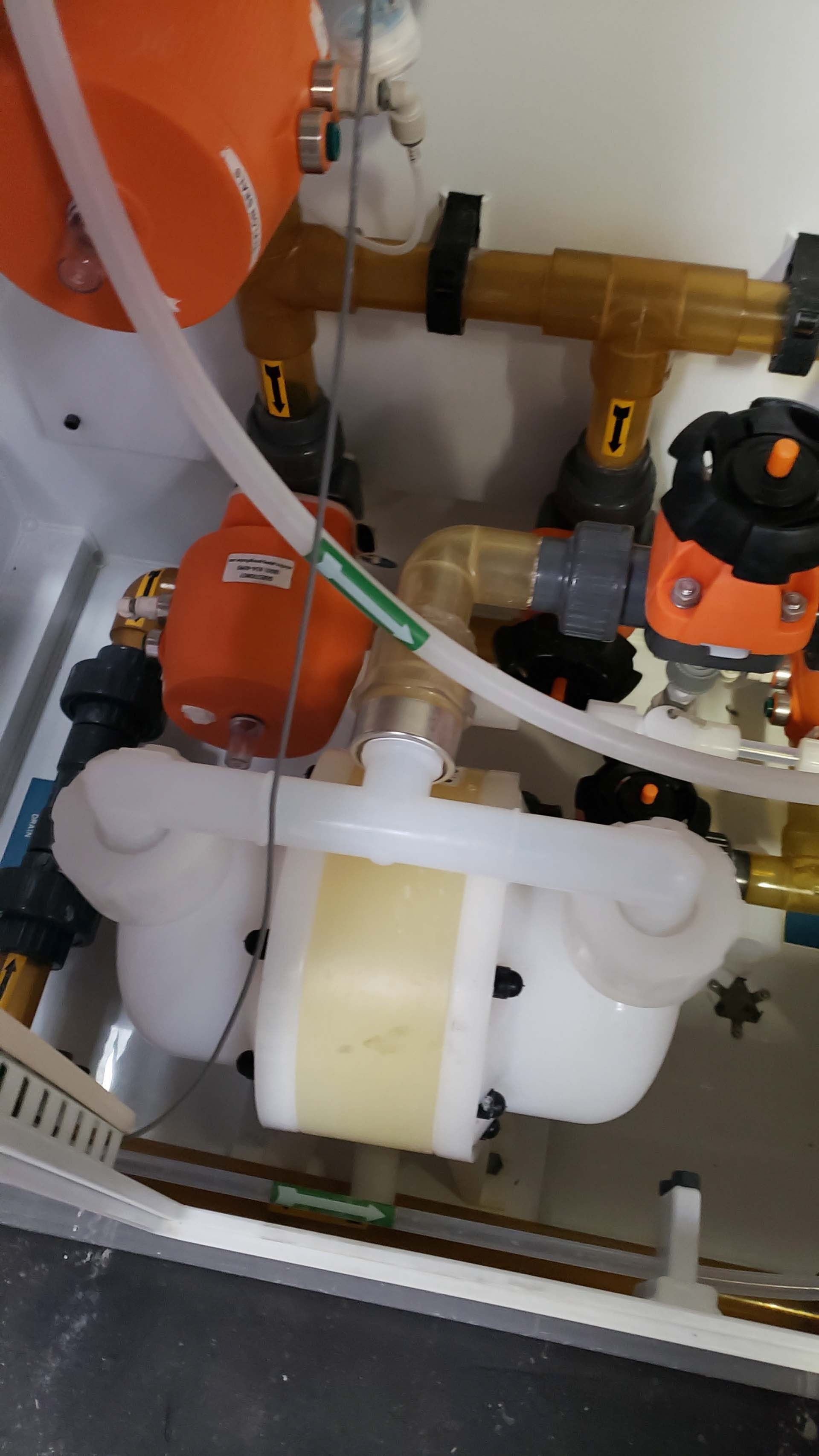

KINETICS MegaFlow II is an innovative wafer processing equipment designed for wafer fabrication. It is capable of accommodating a wide range of wafer sizes up to 8 inches. The system utilizes a state-of-the-art advanced multistage technology to accomplish various processes such as photoresist strip, RTP, epoxy backfilling, leadframe plating, and others. The unit is designed for optimal accuracy, repeatability, mechanical stability, and precision. MegaFlow II begins with wafer loading from the dock. Wafers can be loaded via the open front or side mount. The systems come equipped with a pre-clean station for cleaning the surface of the wafer prior to any process steps. Next, the wafer is transferred to the process station wherein a specific process is performed based on the user's needs. For instance, the RTP process utilizes hot exhaust gas, which is discharged into the furnace to raise the temperature of the wafer. During the heating cycle, the wafer is also mixed with nitrogen or inert gas for controlling the temperature and ensuring a uniform heat distribution. The backside plate process also leverages a hot gas motor to flow heated nitrogen gas around the wafer for homogenous heating. KINETICS MegaFlow II also uses a high-precision tool to accurately measure the wafer after each process to ensure optimal quality control. The machine utilizes a digital display that helps operators monitor parameters like temperature, pressure, and filtration. The tool also comes with data logging capability that stores data for each machine operation. This helps in ensuring traceability of the process. Finally, the waste generated is automatically disposed of in the built-in waste tank. The exhaust asset automatically vents away the vapors produced from the pressure & thermal processes. In conclusion, MegaFlow II is a feature-filled wafer processing solution that offers many advantages to the user. It ensures optimum accuracy, repeatability, and precision; and its automated processes ensure a safe and low risk operation. With all the features offered, it is undoubtedly one of the most reliable and preferred solutions for wafer fabrication.

There are no reviews yet