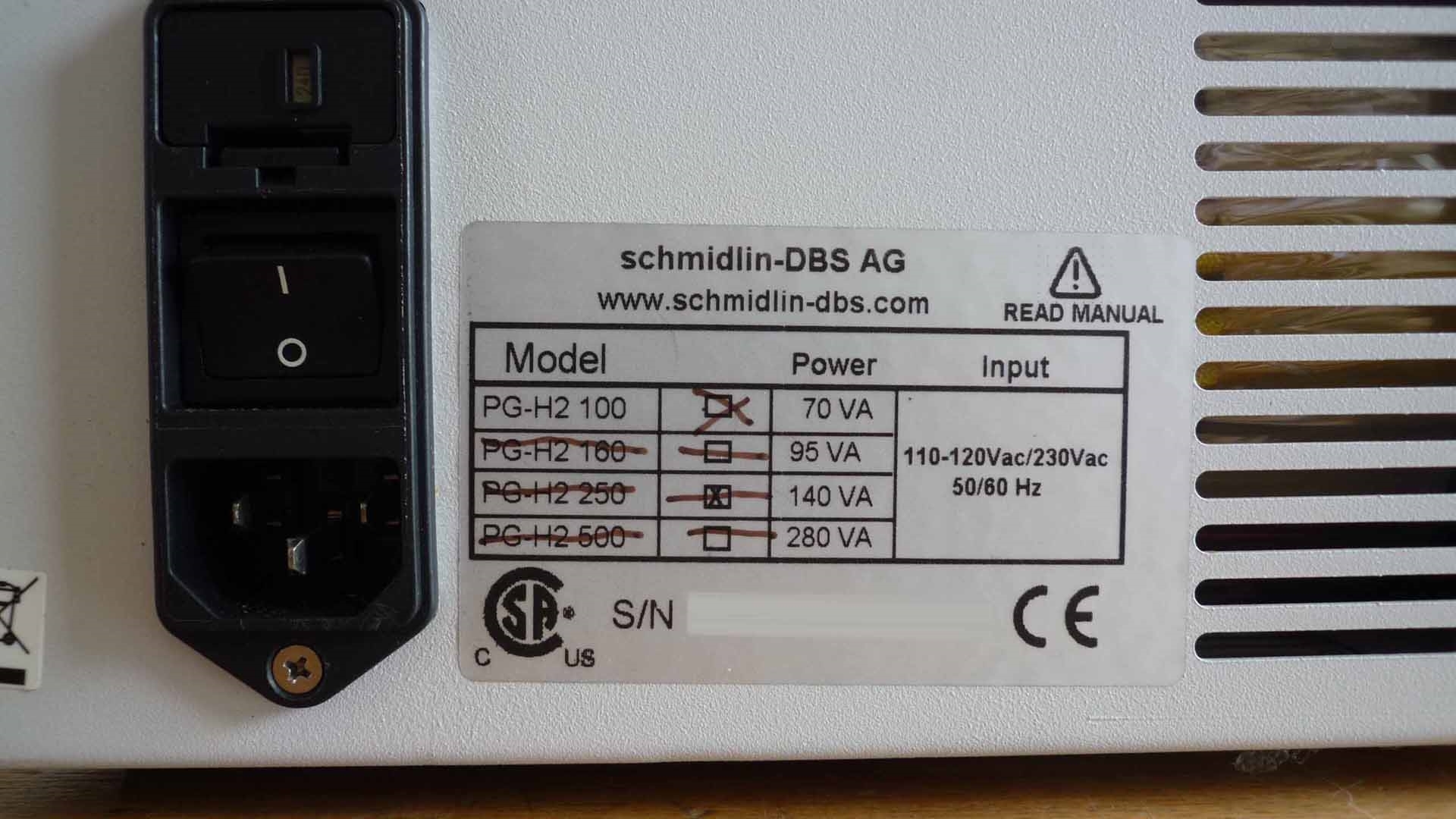

Used LNI SCHMIDLIN PG-H2 100 #9245687 for sale

URL successfully copied!

Tap to zoom

LNI SCHMIDLIN PG-H2 100 is an automated, high-performance wafer processing equipment designed for high-precision wafer fabrication. This machine is suitable for diverse applications, including the production of silicon wafers, MEMS, MEMS sensors, thermopiles, and optical semiconductor wafers. It is largely used for post-growth processing of wafers, such as dry and wet etching, cleaning, coplanarity checking, deposition, ripening, doping, and electromigration. PG-H2 100 wafer processing system consists of two main components, the and the pick-and-place unit. The unit's pick-and-place unit is a multi-axis robot arm that is scalable up to five axes to handle different wafer configurations and pick-and-place operations. It is capable of accurate and repeatable placement of wafers onto substrates. The substrate holder is an adjustable frame with an integrated heating and cooling machine, allowing for easy adjustment of temperatures. The tool is equipped with three main modules for wafer processing: the chemical application module, the PVD module, and the vacuum module. The chemical application module is ideal for controlling the precision of chemical etching with a range of applications including pre-clean and cleaning operations, spray coating, spin coating, and dry etching. The PVD module is a vacuum chamber for physical vapor deposition of metals, polymers, and dielectrics for depositing semi-conductor layers like aluminum and titanium nitride. The last module, the vacuum module, is suitable for processes including RIE, ion etching, plasma cleaning, and oxidation. This asset is designed for easy installation, operation, and maintenance, with an intuitive touchscreen interface and ethernet connectivity. It also comes with a powerful data management model and automatic job scheduling. LNI SCHMIDLIN PG-H2 100 features a safe and operator-friendly environment with a fully enclosed and ventilated enclosure, no need for a cleanroom, and an advanced safety equipment to meet requirements for international standards. This system is capable of producing high-performance wafers with precision, cleanliness, and accuracy in mind. The precision, reliability, flexibility, and safety of PG-H2 100 make it an ideal choice for a wide range of wafer fabrication operations.

There are no reviews yet