Used MICROSENSE EZ 11 #9151871 for sale

URL successfully copied!

Tap to zoom

ID: 9151871

Wafer Size: 12"

Vintage: 2016

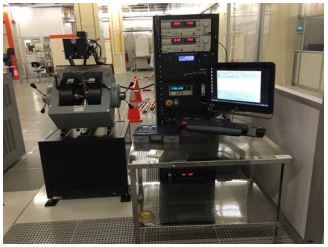

Vibrating sample magnetometer (VSM), 12"

Automatic sample rotation EZ1-VAR

Electromagnet with vibrator and pickup coils

Maximum field at room temperature: 3.2 Tesla

Maximum field at room temperatiure

EZ1-LNA Temperature option in place: 2.7 Tesla

Electronics cabinet

Full set of sample holders

(2) High purity nickel standards, 6mm, 8mm (q=1)

Gaussmeter calibration standards

Computer system including

DVD-Writer (combo)

Color monitor

EZ1-LNA Temperature option: Temperature range 77K + 100K-1000K

Vector coil option with dual signal processor EZ1-SCV-DSP

EZ11 Air cooled chiller

2016 vintage.

MICROSENSE EZ 11 is a wafer processing equipment used to facilitate precision and tight control over fabrication processes. This system is equipped with a highly accurate servo motor for precise repeatability and accuracy. It works by providing ultrafast thermal processing, which can be adjusted to user-defined parameters for improved functionality. The construction of the unit is designed to be simple and easy to use. Its frame consists of an aluminum frame with two levels of support, which is used to hold the wafer during processing. The machine is equipped with a stainless steel cold plate and a heated plate for thermal processes. A single or multiple sample stages can be integrated into the machine based on the desired application. An operator panel is included in the tool, which comprises of switches, indicators, alarms, and emergency stop. The asset is equipped with a motor control unit to ensure precise repeatability and accuracy during the processing process. The motor allows for a variety of movements, such as simultaneous rotation and translation, which enables automated repeatable operations. The servo motor control is used to ensure consistent operation regardless of the external environmental conditions. The model is fitted with an adjustable temperature controller for heating and cooling purposes. The temperature range is adjustable from 0 to 550°C and the temperature controller can be operated in both open- and closed-loop modes. The user-defined parameters can be set to ensure maximum thermal uniformity. The equipment is also fitted with a high-speed digital signal processor, which is used to facilitate fast controllable heat production. The digital signal processor is also used for to regulate the timing of the temperature cycles and thermal ramping periods for each individual process. The user interface for the system is equipped with a graphical user interface, which allows users to set and adjust the parameters for their processes. A variety of math modules are also included, which use the provided data to accurately calculate the thermal gradients and other parameters related to the process. The unit is equipped with a variety of safety features, such as automated shut down processes in the event of power failure. Other safety features include an over-heating protection machine, which can be programmed to ensure optimal performance and increased tool longevity. EZ 11 is a reliable and easy to use asset that ensures excellent performance and flexibility. It is suitable for a wide variety of wafer processing applications, such as general processing, batch processing, crystal growth, electroplating and thin film processes.

There are no reviews yet