Used SAM SM-350 #293647144 for sale

URL successfully copied!

Tap to zoom

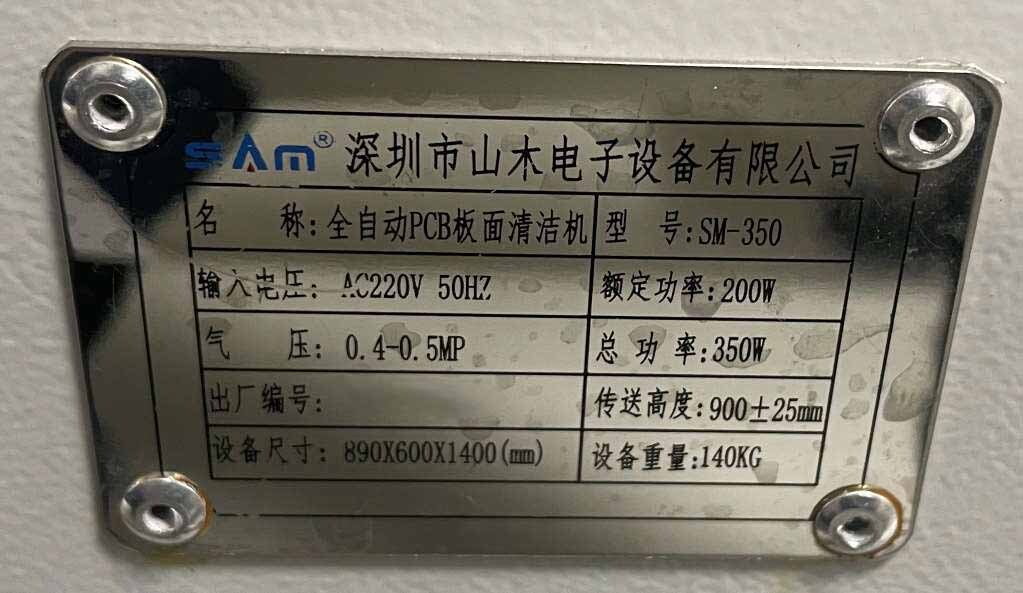

SAM SM-350 is a precision wafer processing equipment designed to provide superior cleaning and inspection services at cost-effective rates. This system is capable of handling up to 6 inches in diameter silicon, gallium arsenide, or quartz wafers with exacting accuracy. Using advanced wet chemical processes, SM-350 offers users precise and repeatable results every time. SAM SM-350 uses four stages of cleaning, including scrub, permeate, scrub and rinse, and final rinse. The scrub process uses an oxidizing surfactant in a programmable-controlled process to ensure complete surface cleaning. The permeate phase utilizes a controlled concentration of chemicals to allow the aqueous cleaning fluid to penetrate and clean deep into the wafer surface to ensure optimal cleanliness. The scrub and rinse process uses ultrasonically, for more effective removing of soils and contaminants from all surfaces of the wafer. Lastly, the final rinse phase utilizes deionized water to completely clean off all remaining chemical residue SM-350 is designed with the user's convenience in mind. Its controls are conveniently located and intuitive interface allows for easy operation of all unit functions. Moreover, the unit offers an amazing array of data output capabilities, including digital process data, detailed wafer logs, cleaning profiles, and tracking of machine statistics. SAM SM-350 is an impressive wafer processing tool that shows great promise in cleaning and inspection jobs. With its wide-ranging features, precise and repeatable results, easy-to-use interface, and superior process control, SM-350 is sure to be an asset to any industrial or scientific process requiring a deep and thorough cleaning of various materials.

There are no reviews yet