Used SATISLOH Blocker PRA #9302745 for sale

URL successfully copied!

Tap to zoom

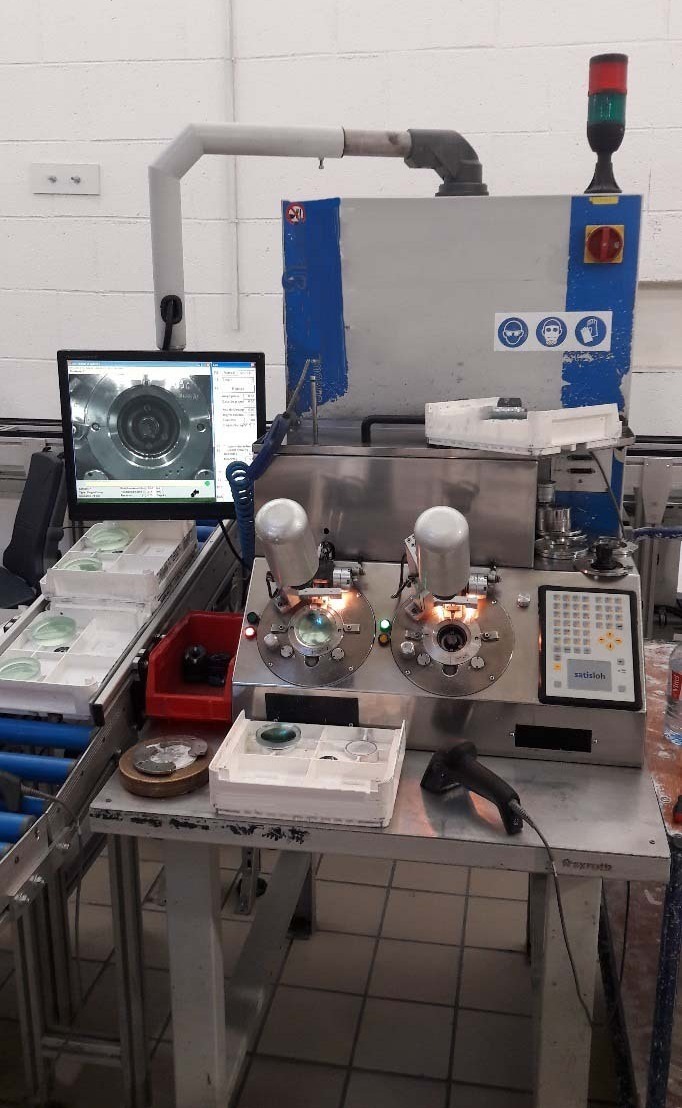

SATISLOH Blocker PRA is a wafer processing equipment developed by SATISLOH that packs a range of advanced production automation technologies. It offers solutions to efficiently manage the complete wafer production process from substrate coating and doping to different wafer processing steps, such as mechanical polishing, wet etch, via etch, chemical mechanical polishing, or wet etch. The system's core feature is its automated loading and unloading processes, which enable quick and efficient wafer transfer between the unit's various processing modules. This reduces downtime and allows for high throughput of wafer production. Blocker PRA also includes a sophisticated sensor machine that tracks the position of each wafer along the production line to ensure the highest quality. The tool has the capacity to store up to 10 thousand recipes for different wafer processing tasks. The asset benefits from its modular design that enables easy integration into existing production lines. Using a range of available control technologies, the model supports a range of processes, including wafer cleaning, mechanical/chemical polishing, etching, planarity measurement, and inspection. Moreover, the equipment also has the capacity to store production records, data reports, and process traceability. The system also enables advanced visualization capabilities. By using a graphical user interface (GUI), operators can monitor, control, and adjust various parameters and other properties of the unit. The GUI also makes it simple to set up different recipes for various wafer processing tasks. Finally, SATISLOH Blocker PRA is designed with safety in mind, and is equipped with various safety features, such as automatic halts and emergency shuts. Furthermore, for the most sensitive production tasks, the machine also includes an optically isolated monitoring tool to ensure safety. In conclusion, Blocker PRA offers a modern and reliable solution for efficient wafer processing. Its flexible design and advanced automated processes reduce production downtime and ensure high quality. Furthermore, its safety features and extensive data storage capacity make it an ideal choice for both small and large scale production applications.

There are no reviews yet