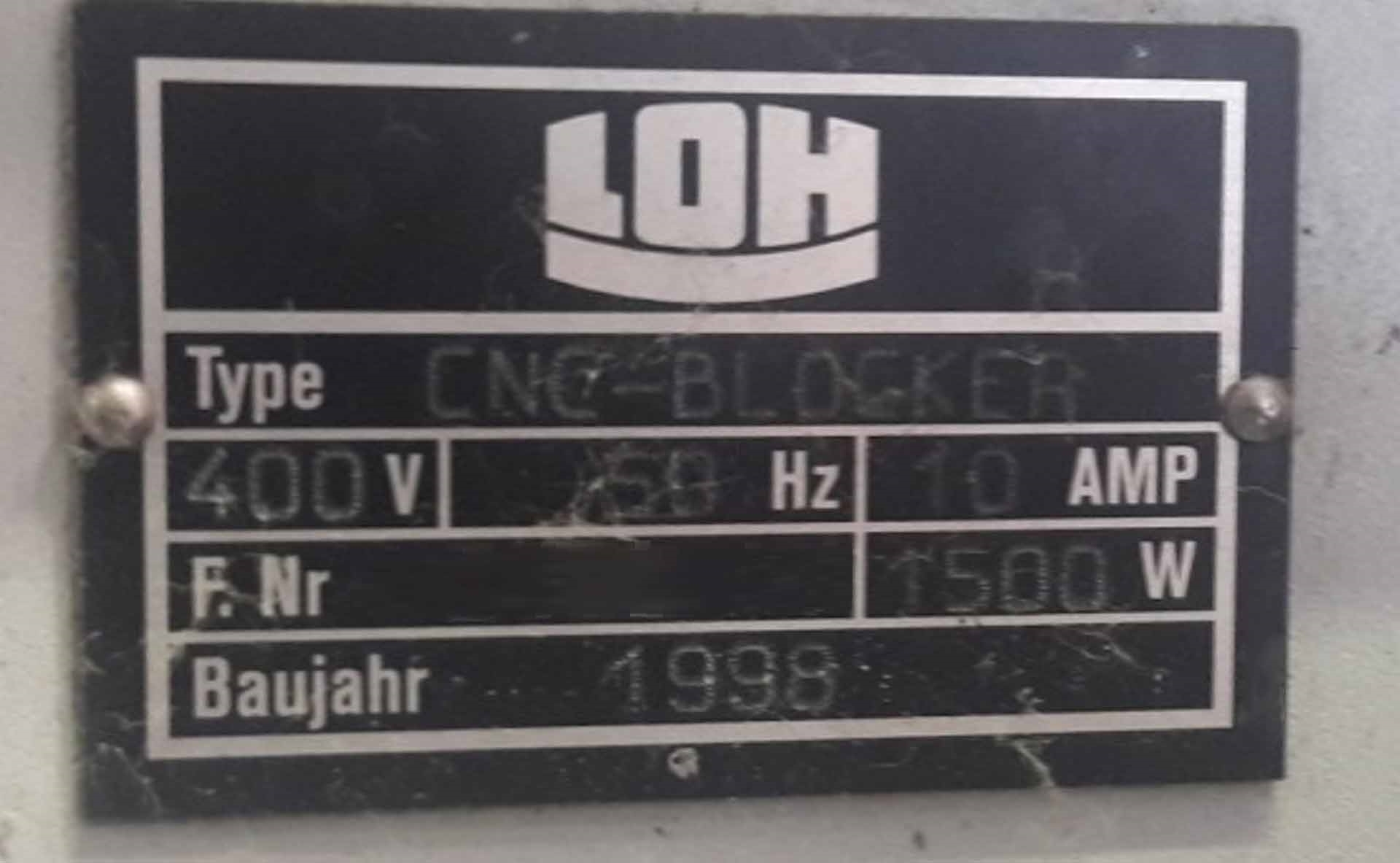

Used SATISLOH Blocker #9218531 for sale

URL successfully copied!

Tap to zoom

SATISLOH Blocker is an advanced wafer processing equipment specifically designed for applications where throughput and accuracy are of utmost importance. The system is made up of several interconnected components, including a processing chamber, a loading station, an unloading station, a control unit, and an auxiliary gas handling machine. The processing chamber, typically a flowing gas or vacuum chamber, is the largest component of Blocker and is used to perform the wafer processing. Inside the chamber, the wafer material is heated to the desired temperature, then exposed to a custom mixture of desired gases and chemicals, all of which are controlled by the control tool that oversees all of the asset's operations. The heated wafer material is then rapidly cooled, cooled again, and then the reaction chambers is flushed with inert gas to ensure that the reaction is complete. The loading station is where the unprocessed wafer material is fed into the model. A robotics arm, programmed with specific instructions, positions the wafer material so that it can be efficiently loaded into the processing chamber. The unloading station is in place for the removal of the processed wafer materials. The robotics arm is also used here to ensure that each processed wafer is unloaded with precision. The control equipment is the brains of the system and is responsible for connecting the various components and overseeing the unit's operations. Different types of control systems are used depending on the size and type of the machine, but all of them monitor the tool's components and make sure each step is executed in the correct order. The auxiliary gas handling asset is used to maintain the quality of the mixed gases used in the reaction chamber, specifically controlling the flow, purity, and composition of the mixture. In summary, SATISLOH Blocker is an advanced wafer processing model specifically designed for applications where throughput and accuracy are paramount. The equipment is composed of several distinct components including a processing chamber, a loading station, an unloading station, a control system, and an auxiliary gas handling unit to monitor and ensure the correct combination of gases are being used throughout the process. Blocker is used in a variety of industries, ranging from semi-conductor manufacturing to food processing, and its innovative design makes it one of the most reliable and efficient systems on the market.

There are no reviews yet