Used SC FLUIDS MEMS Dryer #141020 for sale

URL successfully copied!

Tap to zoom

ID: 141020

Wafer Size: 6"-8"

Vintage: 2002

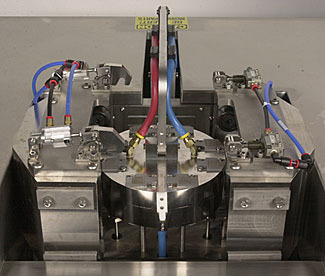

Supercritical CO2 MEMS dryer for single wafer drying, 6" to 8"

Specifications:

Wafer size: 6" to 8"

Ultraclean CO2 delivery system

Point of use particle filter: less than 0.003µ

Solvent separator and water heater

Automated process chamber closing mechanism

PLC controller: stores up to 10 process recipes

2002 vintage.

SC FLUIDS MEMS Dryer is a state-of-the-art wafer processing equipment designed for use in micro-electromechanical systems (MEMS) production. This dryer utilizes SC Fluidic Technolgy's patented heated vapor technology to dry MEMS fabrications. The system boasts an exceptionally low thermal budget, as well as exceptional uniformity when drying. It is designed for the most efficient and accurate drying of the porous layers of MEMS wafers. MEMS Dryer is a fully enclosed, batch processing unit that can process a variety of wafer sizes, from 200 to 400 mm diameter. The machine provides a clean, germ-free work environment. It also features a vacuum tool that can hold a pressure up to 650 mbar, at a temperature of up to 100°C. The heated vapor technology vaporizes water molecules, allowing the wafer surface to remain dry and free of residual moisture. The asset also features automated controls and alarms, allowing for seamless automation and process control. Through its PLC controller, operators can accurately control the temperature, pressure, and time of the drying process. The user-friendly controls and easy-to-use software make the model simple to operate and maintain. SC FLUIDS MEMS Dryer is ideal for high-throughput production. It has a maximum rate of 800 wafers/hour and its automated programs guarantee accurate drying parameters. The equipment also comes with a safety switch for emergency shutoff in the event of unforeseen events. MEMS Dryer is one of the most advanced wafer processing systems on the market. It offers superior accuracy, efficiency, and safety measures. It also boasts outstanding stability, repeatability, and flexibility in its operations. This system is an excellent choice for MEMS fabrications that require precise, reliable drying.

There are no reviews yet