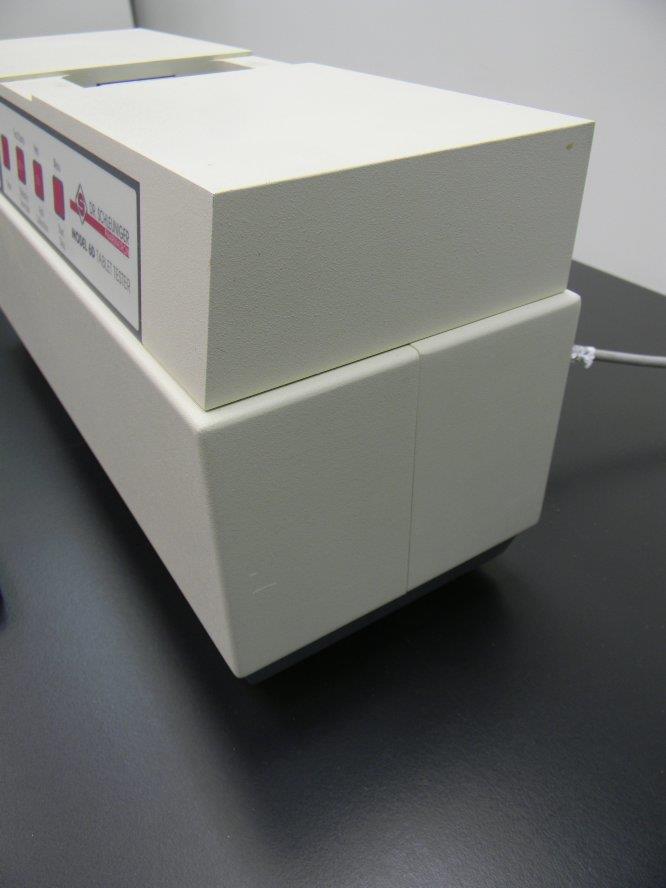

Used SCHLEUNIGER 6D #9127461 for sale

URL successfully copied!

Tap to zoom

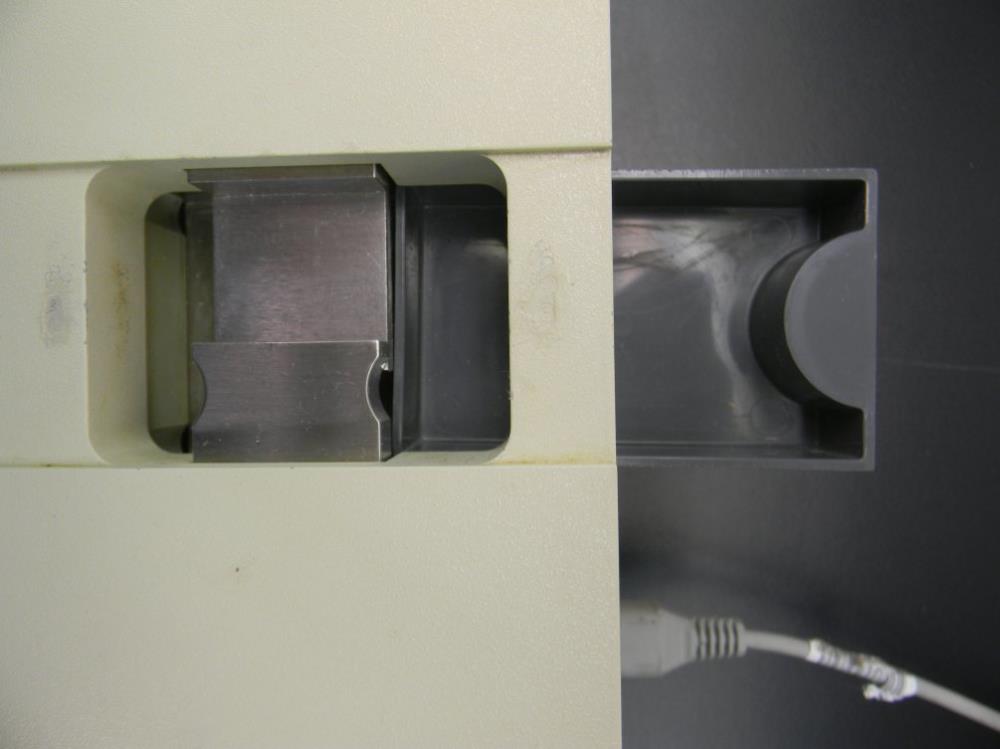

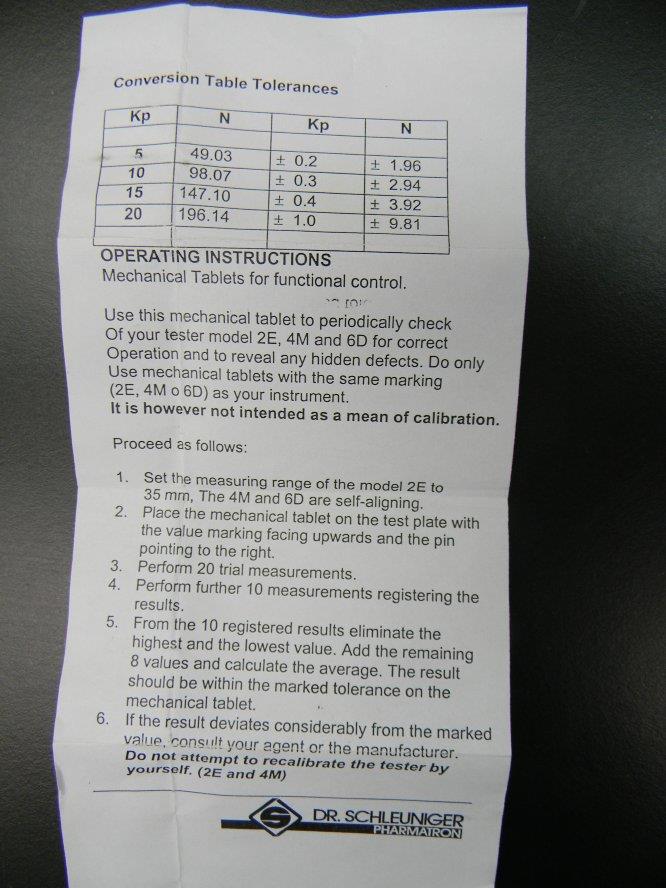

SCHLEUNIGER 6D is a specialized wafer processing equipment manufactured by SCHLEUNIGER AG, a Swiss-based leader in the development of automated precision machines for the electronics, medical device, and telecommunications industries. It is designed for the efficient handling, manipulation, and processing of wafers up to 6-inches in diameter, facilitating the production of complex, high-precision electronic components. The system consists of several components: an integrated wafer-transport unit, stepper motor-driven wafer-transport and alignment machine, pass-through transport tool, conveyor transport asset, and 6-inch end-effector. The integrated wafer-transport model allows the automated rotation and lifting of wafers, enabling precise alignment and positioning of the wafer prior to processing. The stepper motor-driven wafer-transport and alignment equipment provides repeatable, highly precise wafer positioning and alignment with repeatability of 0.5-degree accuracy. Furthermore, the system includes features that prevent wafer misalignment during transport and ensure that parts are properly aligned for testing and processing. The pass-through transport unit consists of an advanced, self-cleaning conveyor transport machine that utilizes a Vacuum Notch Tool (VNS) for improved wafer transport and alignment accuracy. This asset can transport up to 200 wafers per hour over a large-diameter hub and is designed to maintain alignment accuracy regardless of wafer numbers or size. The conveyor transport model has been designed to maximize throughputs by allowing multiple wafers to be processed simultaneously. Finally, 6D features a high-precision 6-inch end effector that can handle various component sizes and shapes with a repeatability of 0.01mm. The end effector has a built-in detection mechanism that can sense the presence of components to ensure accurate spacing, and it also incorporates an independent gripper equipment for secure handling of components during processing. In summary, SCHLEUNIGER 6D is an automated precision machine that facilitates the efficient handling, manipulation, and processing of wafers up to 6-inches in diameter. It includes advanced features such as a pass-through transport system, conveyor transport unit, integrated wafer-transport machine, stepper motor-driven wafer-transport and alignment tool, and a high-precision 6-inch end effector for accurate component alignment and secure handling. It is an ideal solution for those looking for rapid, high-precision production of complex electronic components.

There are no reviews yet