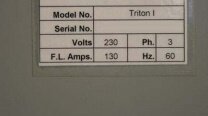

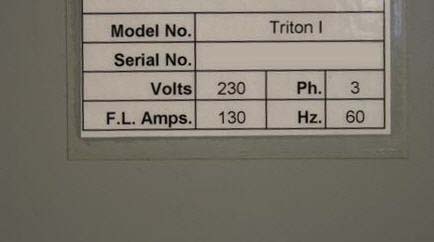

Used STOELTING / TREK / WESTEK Triton I #129982 for sale

URL successfully copied!

Tap to zoom

ID: 129982

Aqueous board cleaner

Maximum board size: 14"

Stainless steel recirculation plumbing

High pressure / high volume stainless pumps

Centrifugal high pressure blower

230 VAC, 130 Amps.

STOELTING / TREK / WESTEK Triton I is a wafer processing equipment designed for cutting-edge fabrication of micro & nano-scale MEMS devices, optoelectronics, and other high-precision components. This state-of-the-art system features a unique "cook-chill" process, enabling precise control over the delivery of both thermal and chemical processes throughout the manufacturing process. TREK Triton I also offers a range of wafer sizes for optimal performance on a variety of substrates—from semiconductor wafers to glass substrates—as well as several different process chambers for deposition, etching, or combination processing. Equipped with the latest in wafer handling software, WESTEK Triton I features an easy-to-use graphical user interface (GUI) with simplified navigation. Its advanced control algorithms allow for easy setup and operation, and the user can also add custom commands and recipes to suit specific requirements. The unit's automate chamber and gas delivery systems also allow operators to quickly switch between processes and substrates, saving on time and costs. Triton I's integrated auto-alignment and wafer recognition systems provide optimal precision in alignment and speed of processing, while its powerful scan and image capture machine allows for ultra-precise inspection of finished materials. The tool also features an integrated vacuum asset, enabling fast, safe, and clean operation. STOELTING Triton I is especially useful for the fabrication of optoelectronics and other large-scale components due to its large process chamber size. The chamber can accommodate a variety of substrates, from small to large sealed or un-sealed substrates, up to a maximum substrate size of 300mm. It also features integrated plasma etching capabilities, as well as reactive ion and plasma-enhanced chemical vapor deposition. All of these features give STOELTING / TREK / WESTEK Triton I the versatility to handle both traditional and custom-fabrication needs. TREK Triton I provides the highest levels of precision for applications such as the fabrication of MEMS sensors, optical components, MEMS actuators, and high-end MOEMS (optical micro-electro-mechanical systems). It is designed to be extremely fast and reliable, allowing for optimal optimization of fabrication cycles and high throughput rates. At the same time, its innovative technologies provide users with maximum safety, as well as excellent repeatability and user-friendly operation. WESTEK Triton I is the answer for those looking for the ultimate in wafer processing systems.

There are no reviews yet