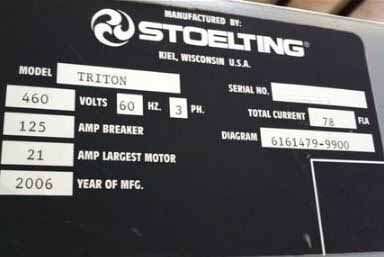

Used STOELTING / TREK / WESTEK Triton #9173227 for sale

URL successfully copied!

Tap to zoom

ID: 9173227

Vintage: 2006

Aqueous inline washer

Polypropylene construction

14" Belt width

Touch screen control panel

Redundant over

Temp and liquid low level safety protection

Digital temperature control for recirculating tank heat

Easy draining stainless steel conveyor rail

Removable tank screens

Adjustable spray pressures

Stainless steel recirculating plumbing

Utility sink

Voltage: 240/460

2006 vintage.

STOELTING / TREK / WESTEK Triton is a high-performance wafer processing equipment, designed for performing both high-precision and high-volume wafer fabrication tasks. TREK Triton is an integrated, fully automated system that can be used to fabricate a wide variety of wafers including silicon, gallium arsenide, and other types of thin films. It is capable of performing high-speed temperature cycling and ultra-clean dry cleaning operations. WESTEK Triton is designed for a variety of process applications in the wafer fabrication industry. The unit is capable of handling up to six wafers at a time and is capable of processing wafers with a thickness range of 150 - 500 microns. It is compatible with a variety of wafer sizes and shapes including 1" (25.4mm), 2" (50.8mm) and 3" (76.2mm). The machine also features a multi-stage inductive heating tool and a multi-zone temperature controller. This allows users to control the temperature of different wafers or plates independently. STOELTING Triton offers a wide range of process options, such as lithographic coating, forming, surfacing, etching, and polishing. The asset also features a fully automated wafer handling model that is compatible with a variety of conventional and robotic handling systems. This allows users to customize the handling equipment according to their specific process requirements. Triton also features an advanced control system that provides users with a high degree of control and accuracy of their processes. This unit includes both integrated machine control software and an optional Human-Machine Interface (HMI). The integrated machine control software allows users to enter and edit wafer fabrication recipes and profiles, which allows them to keep track of their production in real-time. The HMI, on the other hand, allows users to monitor and manage the wafer fabrication process in an intuitive way. STOELTING / TREK / WESTEK Triton is also designed to be highly reliable and efficient, providing a reliable platform for a wide variety of wafer fabrication processes. It is designed with a number of advanced features and safety mechanisms to ensure maximum performance and safety for both the user and the equipment. It also offers advanced options for maintenance and troubleshooting, allowing users to quickly and easily troubleshoot any process or machine issues.

There are no reviews yet