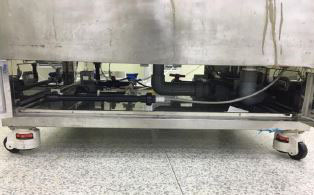

Used ULTECH Ultrsonic #9153462 for sale

URL successfully copied!

Tap to zoom

ID: 9153462

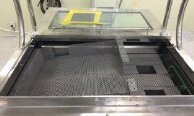

LED Equipment cleaning system

Includes

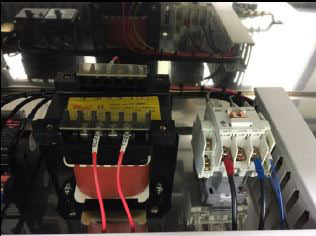

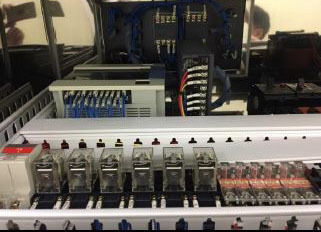

(3) Ultrasonic generators

(1) Control module

(3) Regulators

(1) Pressure gauge

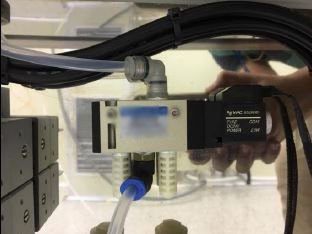

(3) Selenoid valves

(1) PLC.

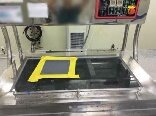

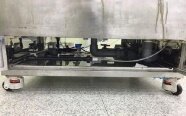

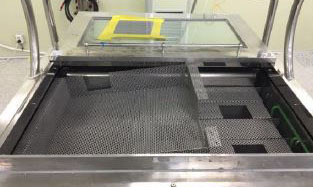

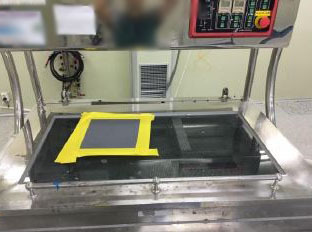

ULTECH Ultrasonic wafer processing systems are used to prepare and clean wafers for semiconductor manufacturing. These systems provide a reliable and repeatable method for removing residues from wafer surfaces, as well as for preparing surface finishes used for bonding purposes. The basic design of ULTECH Ultrasonic wafer processing systems consists of a sound transducer, a tank, and a controller. The sound transducer is designed to generate and transmit ultrasonic waves which will provide the energy needed to break down and remove contaminants from the wafer surface. The tank is filled with a cleaning fluid, usually water, and special chemicals are added to reduce static electricity levels. The controller unit is programmed to control the frequency, amplitude, and duration of the sound waves which will be used to deliver the energy needed for cleaning. The ultrasonic waves generated by ULTECH process are highly effective in removing microbial, inorganic, and organic contaminants. The waves travel beyond the surface of the wafer and cause a cavitation effect to loosen the contaminants from the surface. The cleaning process is further enhanced by the agitation of the cleaning agents in the tank which help to break down and lift the contaminants away from the surface. After the contaminants are removed, the surface finish of the wafer can also be controlled. This is done by adjusting the frequency, amplitude, and duration of the sound waves generated by the transducer. By using lower frequency waves, a fine, uniform finish can be achieved. This finish is used to facilitate adhesion of packaged devices and is necessary for reliable backgrinding processes. ULTECH ultrasonic wafer processing systems are used in a wide range of industries, including aerospace, automotive, and medical, as well as in the manufacture of semiconductor devices. The systems are easy to use and provide a cost-efficient, repeatable and reliable method for preparing and cleaning wafer surfaces.

There are no reviews yet