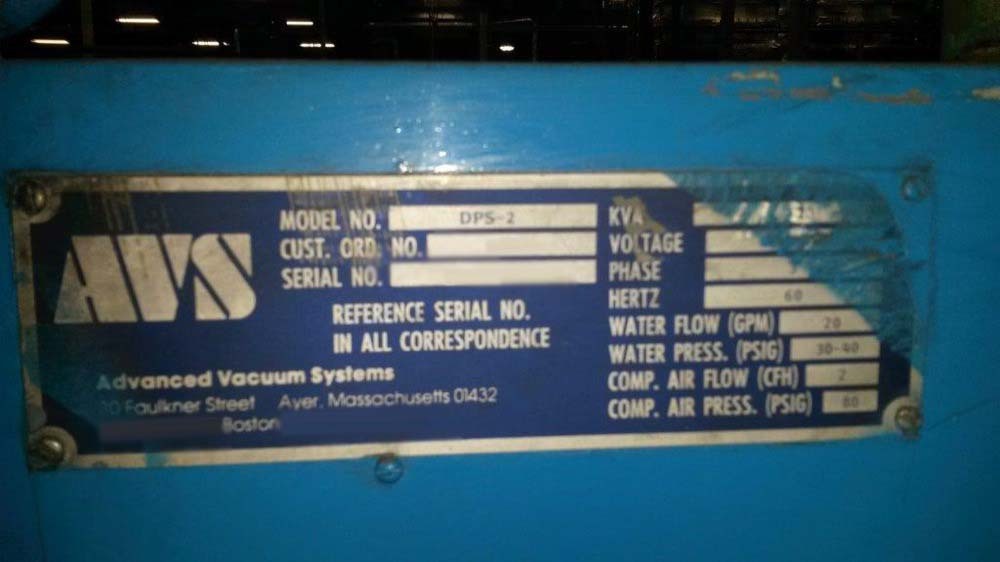

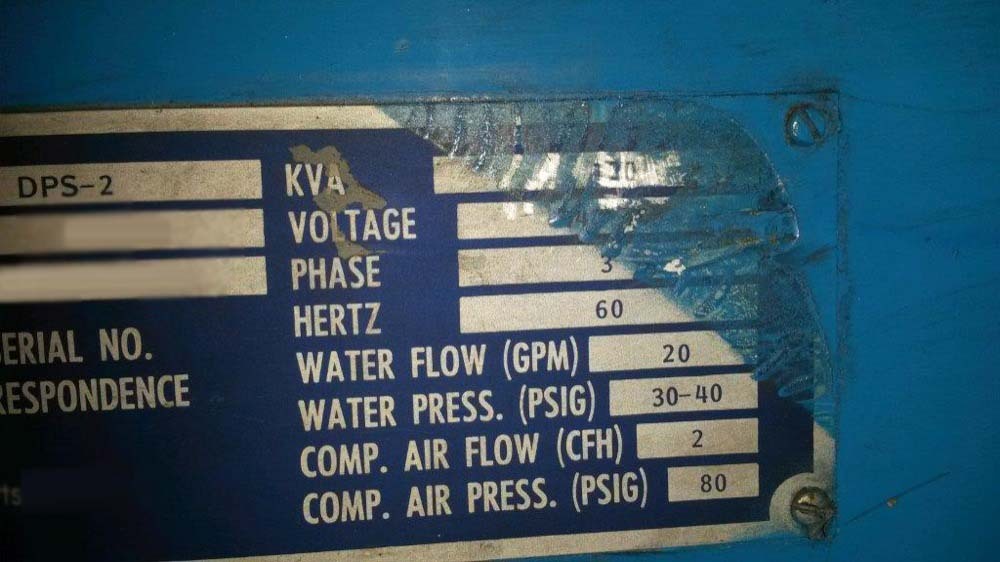

Used ADVANCED VACUUM SYSTEM DPS-2 #9078812 for sale

URL successfully copied!

Tap to zoom

ID: 9078812

Vintage: 1986

Vacuum sintering furnace

Temperature: 1600°C

Hydrogen burn off

Graphite hot zone

1986 vintage.

ADVANCED VACUUM Equipment DPS-2 is an advanced, multi-functional plasma etch/deposition system. It is used for etching and depositing thin films on substrates in a high vacuum environment. The unit features a station based construction, using two independent chambers to allow dual operation. The standard model includes an inductively coupled plasma source, a vacuum antechamber, a turbo-molecular vacuum pump with a xenon-gas dosing valve, a flexible drive mechanism and a freely configurable process chamber. The vacuum antechamber houses two large gates, an evaporation source, and a quartz crystal microbalance. The turbomolecular pump allows high vacuum operation, while the gas dosing valve provides users with precise control over the gas loadings. The drive mechanism enables robust, low-vibration positioning and the modular design ensures that the machine is easily scalable and upgradable. The central heart of the tool is the inductively coupled plasma source (ICP), which is used to generate a flame-like flame to etch or coat the substrates. The ICP is designed to provide highly uniform plasma deposition, with excellent repeatability for consistent film quality. The ICP has a wide range of power levels, adjustable from 1 to 3 kW, making it suitable for a variety of applications. It is mounted on a robust frame with a highly adjustable gas inlet and outlet, allowing users to accurately control process variables. The process chamber is sealed with three vacuum seals. It is equipped with a 50 mm quartz window, a vacuum gate valve, and an integrated heater. The quartz window provides a visual access to the process chamber, while the gate valve maintains the internal pressure of the process chamber. The built-in heater provides the thermal energy required for coating and etching processes. DPS-2 is designed to be used in a wide range of applications. It is suitable for ultra-high vacuum applications, as well as high-throughput, industrial-grade production processes. It is capable of producing a high-quality thin film with excellent uniform coverage and repeatability. The asset is compatible with a range of substrates, such as wafer, ceramics, plastics, and other materials. It is also capable of multiple etch cycles with consistent results. Overall, ADVANCED VACUUM Model DPS-2 is a powerful, versatile plasma etch/deposition equipment, suitable for a wide range of applications. It provides excellent uniformity and repeatability, and is proven to be reliable and efficient. With its robust design and easy scalability, the system is the ideal choice for industrial, production-level processes.

There are no reviews yet