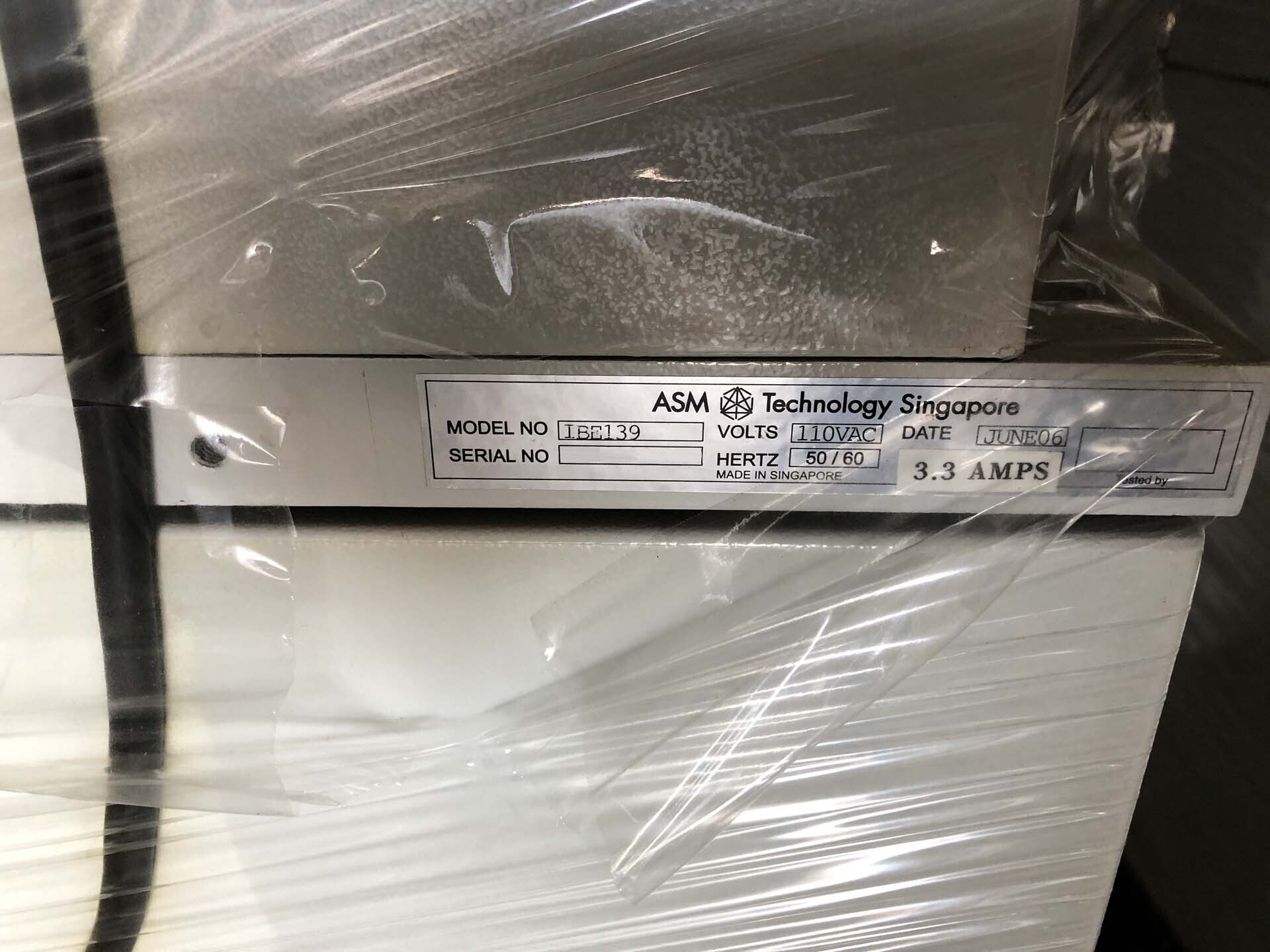

Used ASM COE 139 #9300861 for sale

URL successfully copied!

Tap to zoom

ASM COE 139 is a high-temperature oven and furnace specifically designed to meet the exacting requirements of an electroplating industry. It is a continuous, programmable oven with a digital temperature controller and a built-in cooling equipment. The oven is designed to provide a controlled temperature profile with uniformity across the entire product, as well as providing consistent plating thickness over the entire area heated. This is achieved through an adjustable furnace atmosphere, which includes a calibrated range of available temperatures, and an accurate thermocouple system for readouts and control. ASM COE139 features a highly efficient heating unit that delivers a temperature-controlled atmosphere to uniformly treat both parts and products. With its digital programmable control machine, users can easily adjust the temperature and time parameters of any given cycle and set an even, constant level for the entire product. It also eliminates hotspots and cool spots, which can cause inconsistencies in plating or reduce product quality. The oven and furnace surface is constructed with a unique coating for easy cleaning and maintenance that resist temperature scaling and discoloration. The oven wall has an air gap to minimize heat loss and for better insulation. COE 139 also features a high capacity cooling tool that includes a high-efficiency fan. This fan helps dissipate heat generated by the interior of the oven, ensuring a uniform temperature throughout the entire chamber. Inside the oven is a uniformity survey bar, sample holders, and a thermocouple assembly. The bar is designed to measure the internal temperature uniformity to make sure that there are no hot or cold spots inside the oven. The sample holders and thermocouple assembly can be used for measuring actual sample temperatures. Overall, COE139 is an efficient and reliable oven and furnace, and allows for controlled temperature profiles across a wide range of industrial applications. It is well-suited for meeting the demands of many processes such as preheating, curing, annealing, brazing, soldering, sintering, melting, and plating, among others.

There are no reviews yet