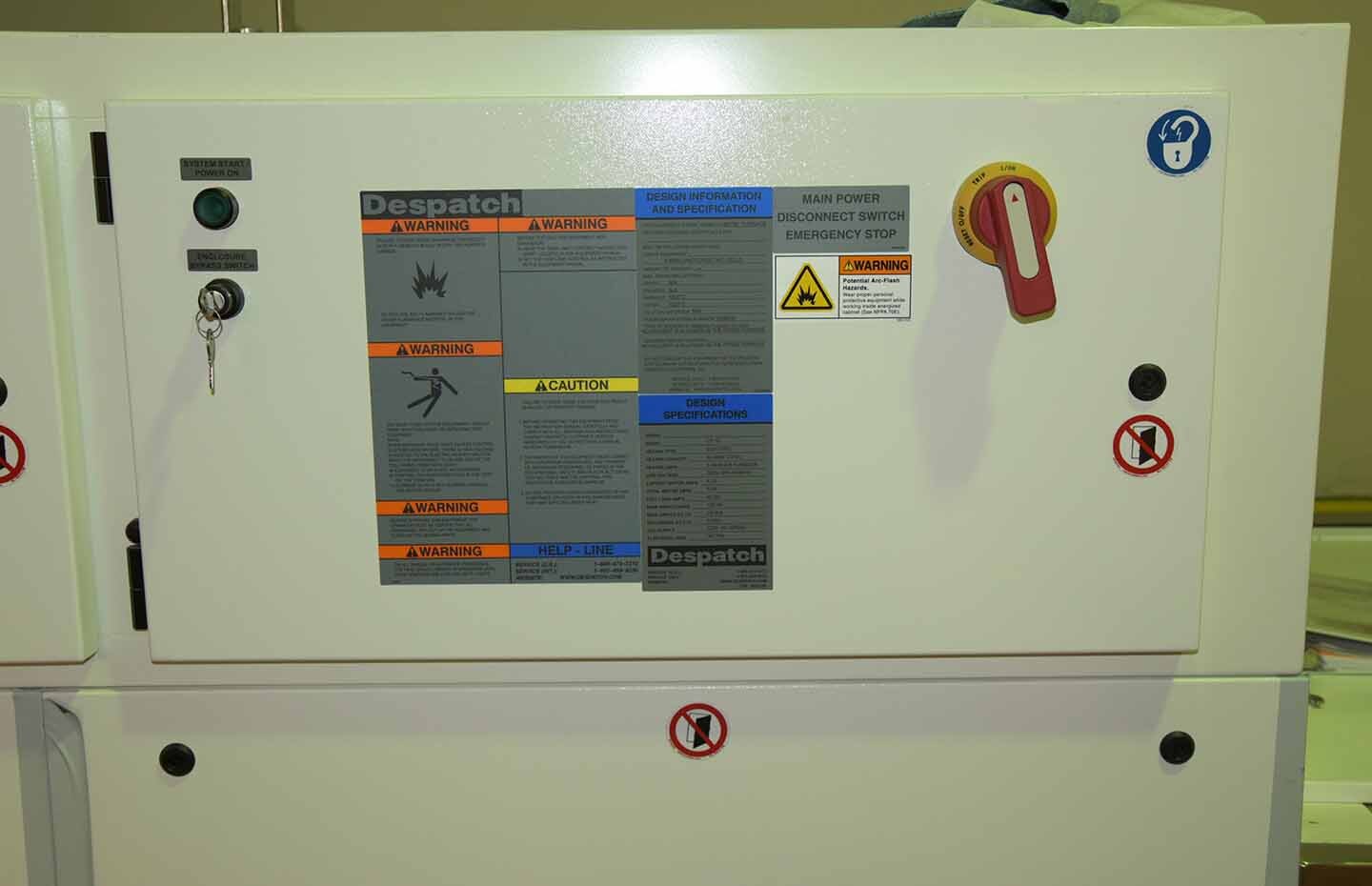

Used DESPATCH CF-SL #9202349 for sale

URL successfully copied!

Tap to zoom

ID: 9202349

Vintage: 2014

Metallization firing furnace

Accurate temperature profile conveyor

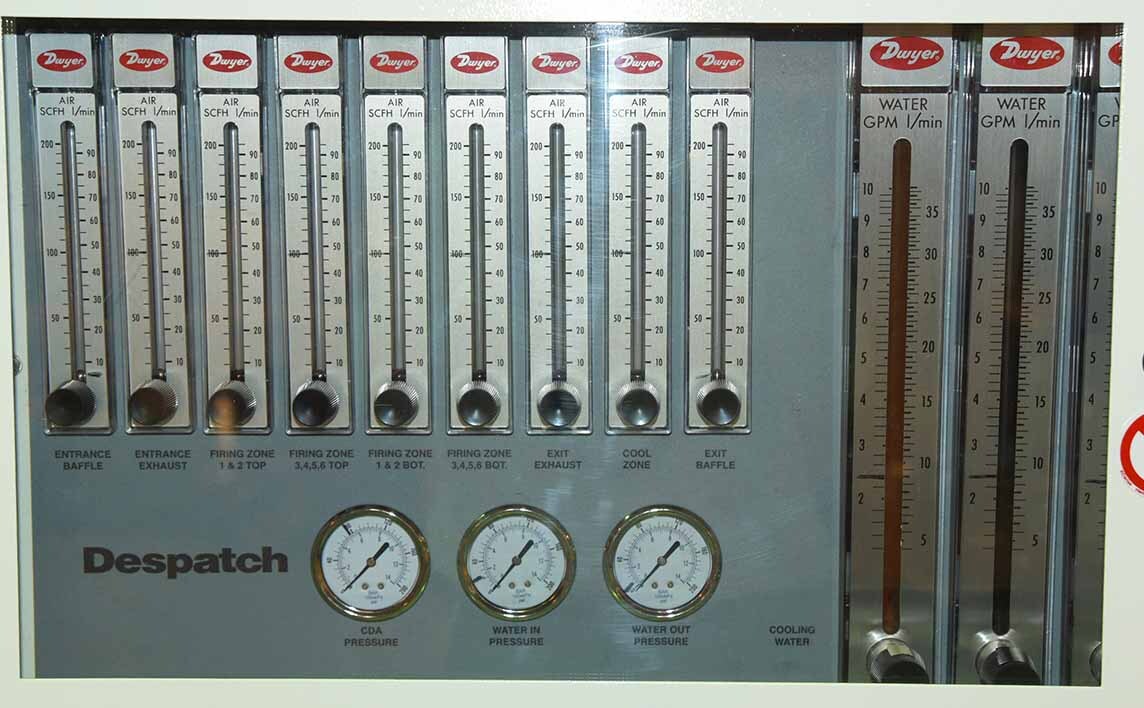

Water requirements:

Typical flow: 11 lpm

Pressure (Maximum): 4 Bar (60 psi)

pH Level: 7.2-7.6

Inlet temperature: 16-18°C (59-64°F)

Exhaust:

Cabinet exhaust: 850 M³/hr (500 SCFM)

(2) Process exhaust venturi assist hoods

Process atmosphere:

Clean dry air: 19 M³/hr (11 SCFM)

Process capabilities:

Maximum temperature: 1000°C

Conveyor speed range: 66-762 cm/min (26-300 Ipm)

Conveyor speed accuracy: ± 0.5%

Throughput (6"x6" / 156 mm x 156 mm wafers): Up to 2,500 wafers/hour

Edge support for cells on conveyor belt provides more consistent heat

Without shielding by supports cells

Burnout

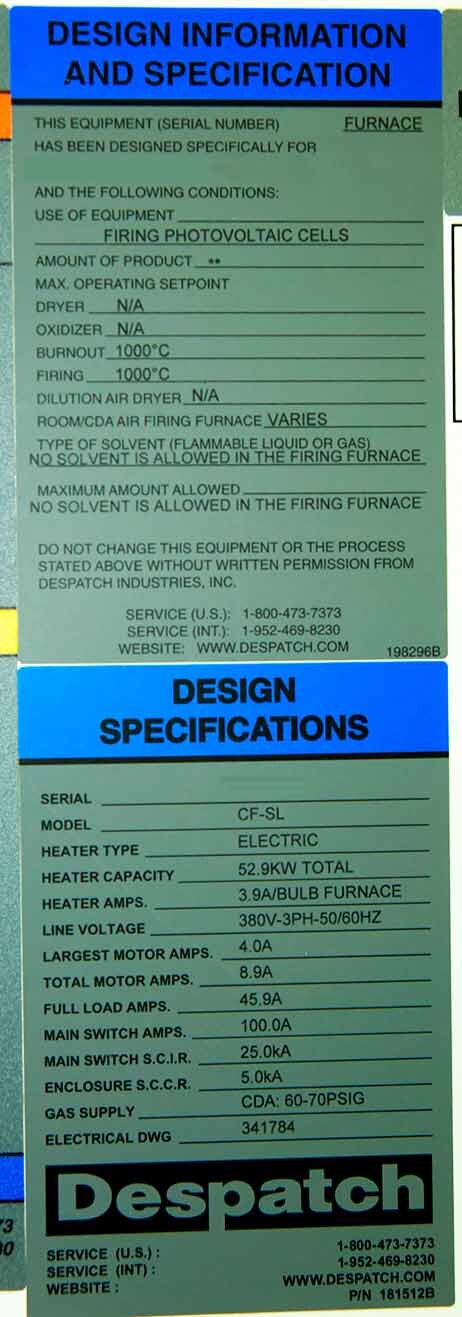

Heater capacity: 52.9 kW (Total)

Heater: 3.9 A / Bulb furnace

Largest motor: 4.0 A

Total motor: 8.9 A

Full load: 45.9 A

Main switch: 100.0 Amps

Main switch S.C.I.R: 25.0 KA

Enclosure S.C.C.R: 5.0 KA

Air supply:

CDA: 60-70 PSIG

Electrical requirements:

Connected load: 46 A (38 kVA)

Typical operating load: 32 A (26 kVA)

Transformer to operate: 460 V

Power: 380-480 V, 3-Phase, 50/60 Hz

2014 vintage.

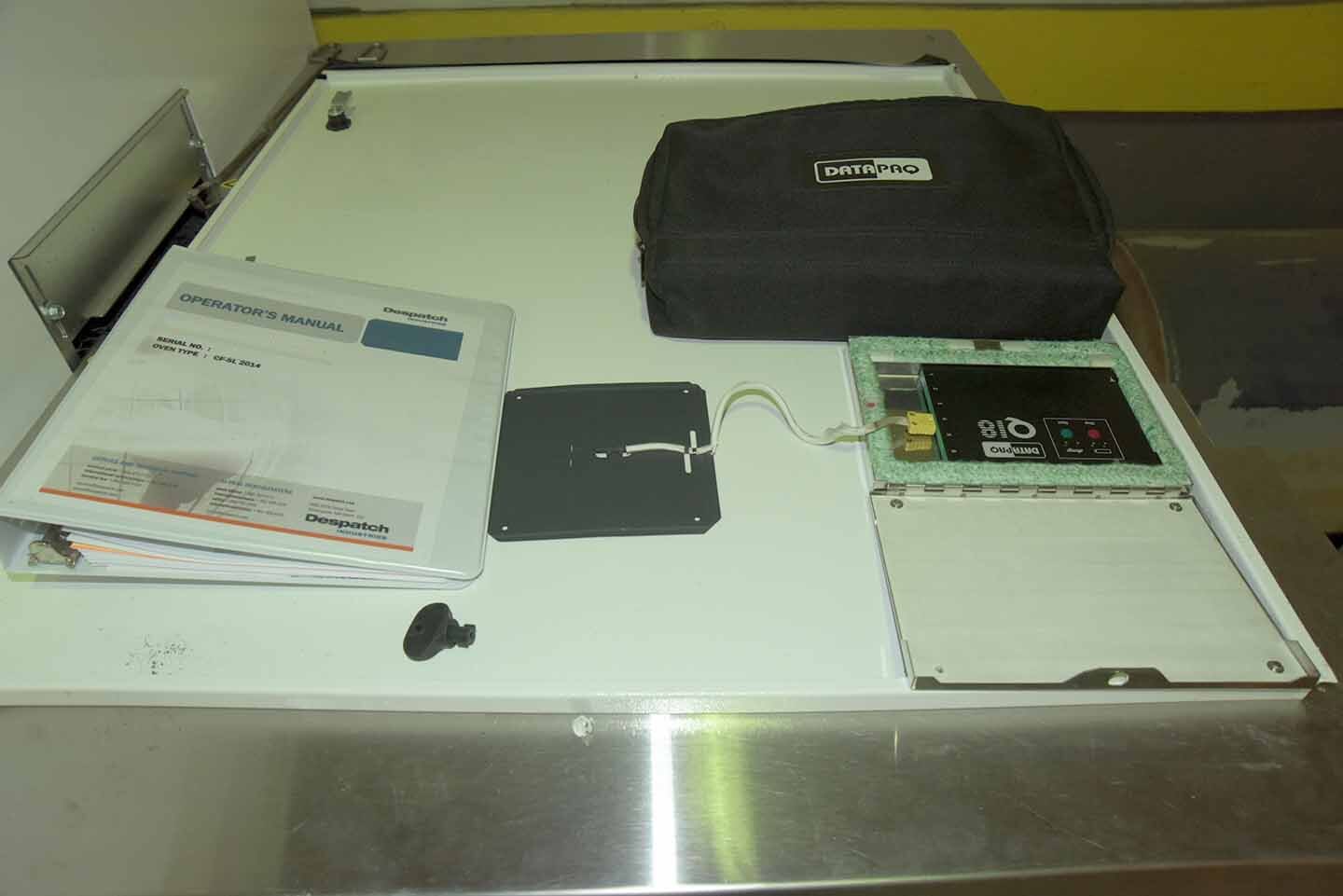

DESPATCH CF-SL is a combination forced air convection / high-speed air impingement oven / furnace. This industrial oven is designed for rapid heat-up and cool-down of production materials. It is simple and economical to install, with advanced temperature control capabilities. CF-SL is a cabinet oven, with a rectangular internal chamber measuring 36" W x 36" D x 46" H and a maximum temperature of 1000°F. The oven is designed to efficiently heat single sided or double sided parts, with a 300-200°F temperature variation at the top and bottom of the chamber. The oven has two forced air blowers, a 7-inch and a 5-inch blower. The airflow is adjustable, providing uniform heated air throughout the chamber. The oven utilizes a high-speed air impingement equipment to direct high-velocity heated air towards the parts, providing fast and uniform heating of the parts. DESPATCH CF-SL is equipped with dual-zone temperature control, where the top and bottom of the chamber can be maintained at different temperatures. This allows for improved product quality control, as the parts can maintain consistent temperatures throughout processing. Additionally, the oven has a precision PID temperature control system for precise temperature control. The oven is insulated with fire resistant ceramic fiber blanket, allowing for 4 - 6 hours of unattended operation and reducing energy loss. The oven has a halogen temperature indicator light to indicate when peak temperature has been reached, saving energy. The oven is also equipped with a shut-off timer to keep the oven from overheating. Additionally, the oven has optional features including timer-controlled cooling, manual standby operation, humidity compensation, and optional Cool/Heat dual unit capability. The Cool/Heat dual machine allows the oven to cool the chamber below room temperature, providing quick cool-down of parts. CF-SL oven was designed for pre-heat, thermal cure, assembly and paint bake applications. It features a removable high temperature work platform, and two integrated fork lifts for quick and easy loading and unloading. The heating elements in the oven are high temperature rated, ensuring safe operation and long life. The oven can be built to enhance safety, with a stainless steel exterior, mesh door guard, and additional safety guards. Overall, DESPATCH CF-SL is an efficient, economical, and safe oven/furnace with advanced temperature control capabilities. It is ideal for processes that require rapid heating and cooling, and can accommodate a variety of applications.

There are no reviews yet