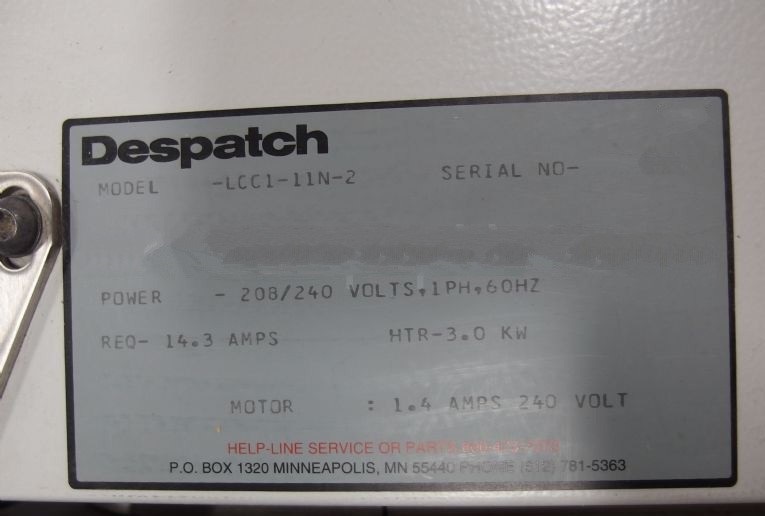

Used DESPATCH LCC-11N-2 #9152454 for sale

URL successfully copied!

Tap to zoom

ID: 9152454

Oven

Material of construction: Stainless steel

Temperature range: 260 deg C

Currently warehoused.

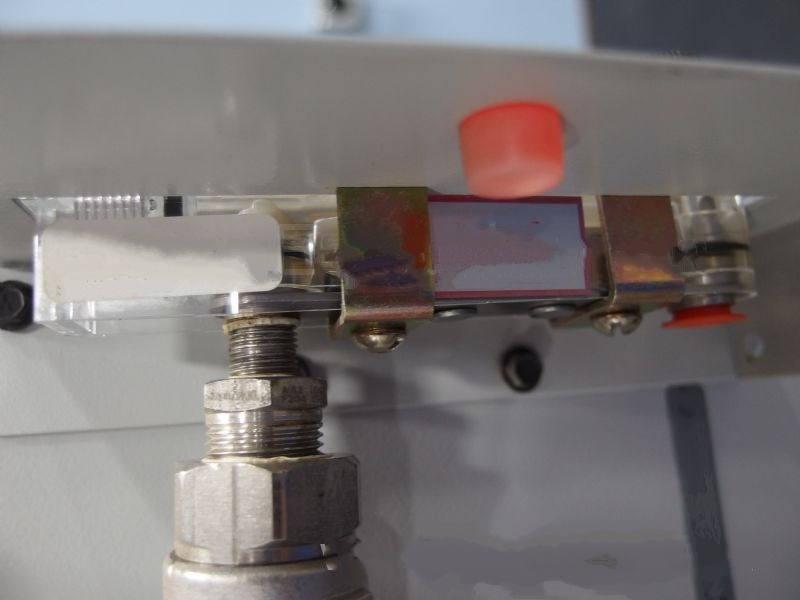

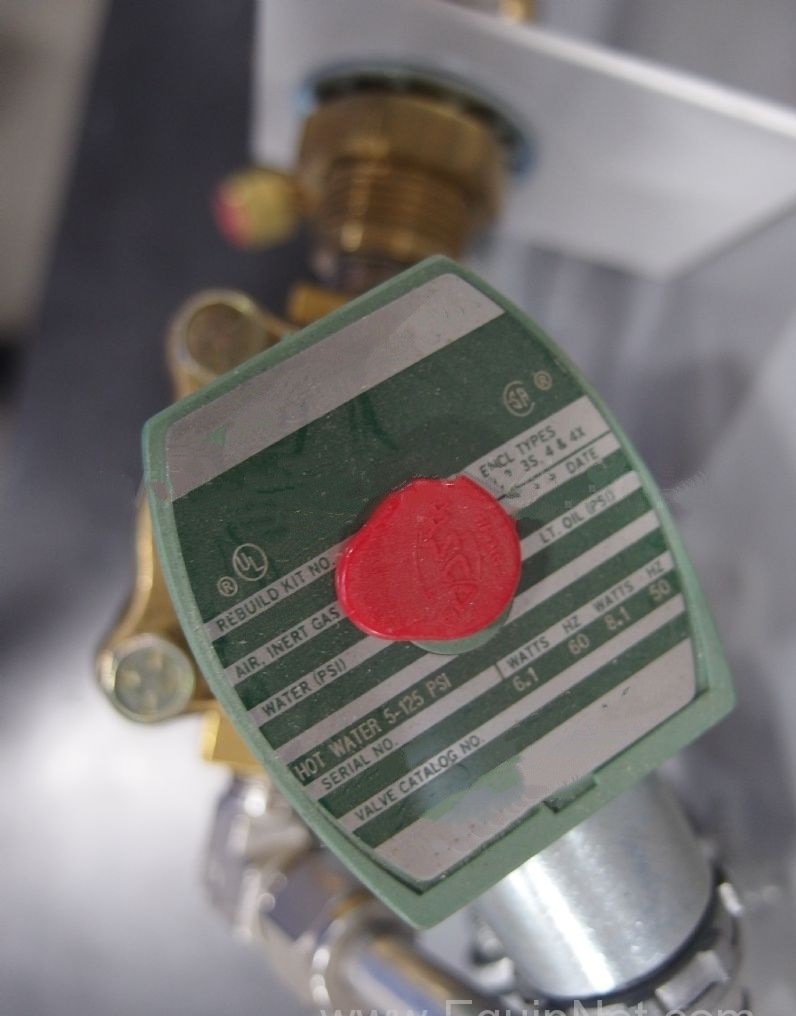

DESPATCH LCC-11N-2 is a large chamber conveyor furnace designed for uniform heating of a variety of materials. This model features a split cross-flow atmosphere and two independent chambers for improved temperature uniformity and enhanced productivity. The operating temperature of this furnace ranges from 500°F to 1700°F (260°C to 927°C). LCC-11N-2 is equipped with proprietary air recirculation and profile-tracking systems, designed to reduce heat loss and increase energy efficiency. This convection process distributes heat evenly and maximizes product quality. The oven features an advanced hot face construction that is optimized for long-term durability and superior heat transfer to the products being processed. In addition, the hot face consists of a low mass ceramic-welded material that improves heat transfer and increases the mechanical strength of the furnace. The furnace body is constructed from thick-wall steel that is designed to withstand high temperatures and maximize process repeatability. The chamber is equipped with a combustible gas detection system and has manual and automatic purge capabilities. The furnace also features a programmable logic controller (PLC) to control processing parameters, and an HMI (human-machine interface) for operator monitoring. DESPATCH LCC-11N-2 is designed for superior performance with improved temperature uniformity and increased process repeatability. This convection oven offers flexible, efficient processing of parts with precise temperature control. The furnace is suited for applications that require repeatable thermal processing at low, medium or high temperatures. This furnace allows for processing of parts with various geometric shapes and sizes from very small to large components. The system is designed for operation with natural gas and is available with an integrated exhaust extractor that removes combustion byproducts for a safe working environment. This unit is also capable of operating in an inert atmosphere, such as nitrogen or forming gas, which can be used to minimize oxidation and improve process repeatability. A fresh air intake vent and energy conservation measures are also included in the design to reduce fuel consumption while ensuring optimal performance. LCC-11N-2 is designed with advanced safety features, including temperature override limit controls and a myriad of safety interlocks. This heavy-duty oven has three independent temperature control zones that enable precise heating and cooling of each chamber. The furnace also includes heavy-duty loading and unloading features and a remote operation switch unit for increased safety. The furnace can be used in manual or automatic operation modes, to allow for hands-free loading and unloading. Overall, DESPATCH LCC-11N-2 is a robust industrial oven that offers precise temperature control, programmable process parameters and improved productivity. The furnace is suitable for a variety of thermal processing applications that require uniform heating of parts at high or low temperatures. The model also features advanced safety features and energy-saving options, making it an ideal choice for industrial production.

There are no reviews yet