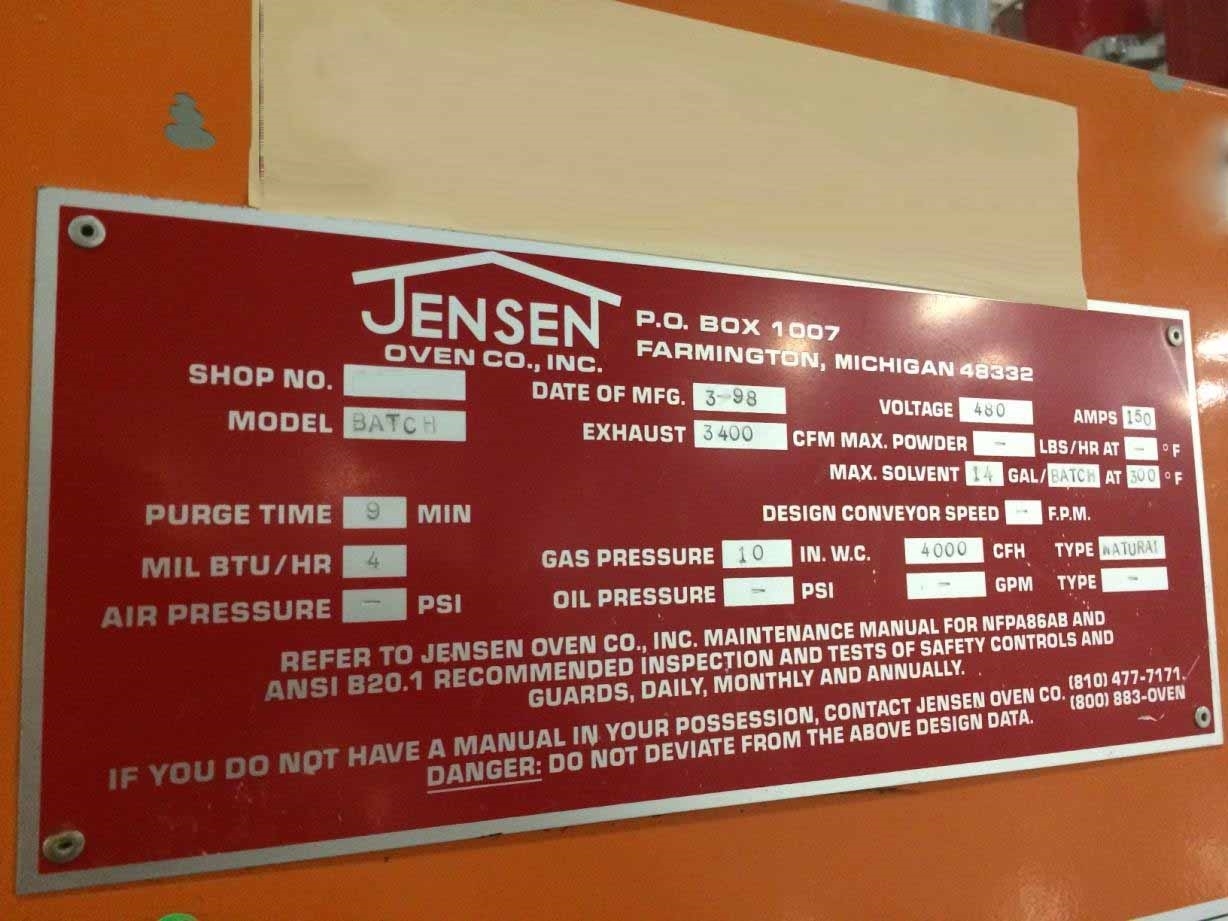

Used JENSEN BATCH #9207025 for sale

URL successfully copied!

Tap to zoom

ID: 9207025

Vintage: 1998

Cure oven

Exhaust: 3400 CFM

Power: 480 V, 150 A.

1998 vintage.

A JENSEN BATCH is an industrial oven or furnace which is used in a variety of industries to heat products or materials to a desired temperature. It is designed to meet the most exacting standards in both temperature uniformity and process repeatability. This ensures precise results are achieved, and reproducibility and dependability are maximized. BATCH oven can operate at temperatures ranging from -10 degrees Fahrenheit up to 1400 degrees Fahrenheit. It is typically used for curing, tempering, baking, drying, aging, thawing, and annealing. It features a steel construction with a wide array of available temperatures, sizes, configurations and atmospheres. The oven also offers fast ramp up and cool down times, allowing for increased productivity and throughput. JENSEN BATCH oven is designed with a vented top heating chamber and is insulated with ceramic fibre insulation or both sides of the oven with optional stainless steel temperature control panel. The insulated chamber allows for lower thermal losses and excellent temperature uniformity, while the stainless steel panel provides accurate temperature control. The oven also features an automated cycle control system for both temperature and time settings, ensuring a reproducible process every time. The oven also offers an array of safety features to ensure that safe working conditions are maintained, such as over temperature protection, an exhaust blower system, and flame safety devices. The exhaust blower helps to reduce odors and smoke during the heating process, while the flame safety devices shut down the oven if a fire is detected. Additionally, the oven can be equiped with optional features including an electronic data logger, air filtration devices, and a charging system. BATCH oven is an ideal solution for meeting the needs of a variety of industrial processes. With its wide variety of features, safety systems, and customizable options, it can help to provide reliably precise, reproducible, and dependable results for any production line.

There are no reviews yet